T&I News 16 2021…

There has been plenty going on this week, so it is nice to compile a detailed blog post recording some of the activity. I tend to start the post mid-week, then finish it off on a Friday (this is my excuse for it occasionally looking a bit like a cut/paste job!) as it is a matter of record, as well as a news feature. Friday also saw us operate Coffee Pot for another of its advertised steaming days, with Matt and I deciding we needed some steam therapy ourselves, which meant the narrow gauge railway was also operational. It was also a chance for us to review some fencing and access features as next week, all being well, a significant amount of new fencing will start to be installed to open up the narrow gauge to visitors and improve access for viewing of the railway.

Tramway

The need to be able to move tramcars around the depot and carry out shunts (including to access the pit) resulted in a working party by the Beamish Tramway Group carrying out some preparatory work to enable trams to be shunted under their own power within the confines of the depot yard only (for now). Work included insulation (or mega) testing of the electrical circuitry on each tram, Blackpool 31 and Oporto 196 being the first two candidates (others to follow in due course). One move that is needed is the extraction of the Coop mobile shop, that is stored on our large trailer within the depot. The shop is to be placed into deep-store, and the trailer requires repair before it can be used again (for example, at harvest time).

Below: A live line in the depot yard…

Below: The team works on Blackpool 31 in preparation for its first move since March 2020.

Below: Some bulbs in the line alive/earthed indicator were replaced as part of the substation and switchgear recommissioning work.

Below: An empty space!!! Sunderland 16 and Sheffield 264 will receive attention and testing later this month, whilst Newcastle 114 is still partially dismantled following motor work pre-lockdown. As can be seen, the tram depot has become quite a multi-user space, so removing some of the road vehicles will help reinstate it as a working depot once again.

Gateshead 10

Below: The first of the pony truck axle boxes to receive attention is seen here. Chris has built up the thrust face with weld (the silver strips visible on the faces nearest to the camera). These will then be machine don the horizontal borer to reinstate the correct clearance and face profile.

Incidentally, quick access to posts regarding Gateshead 10 (or British Railways 26 if you prefer) can be found on the black-backed menu at the top right of the page (not when viewed on mobile phones) under ‘Tram Restorations’.

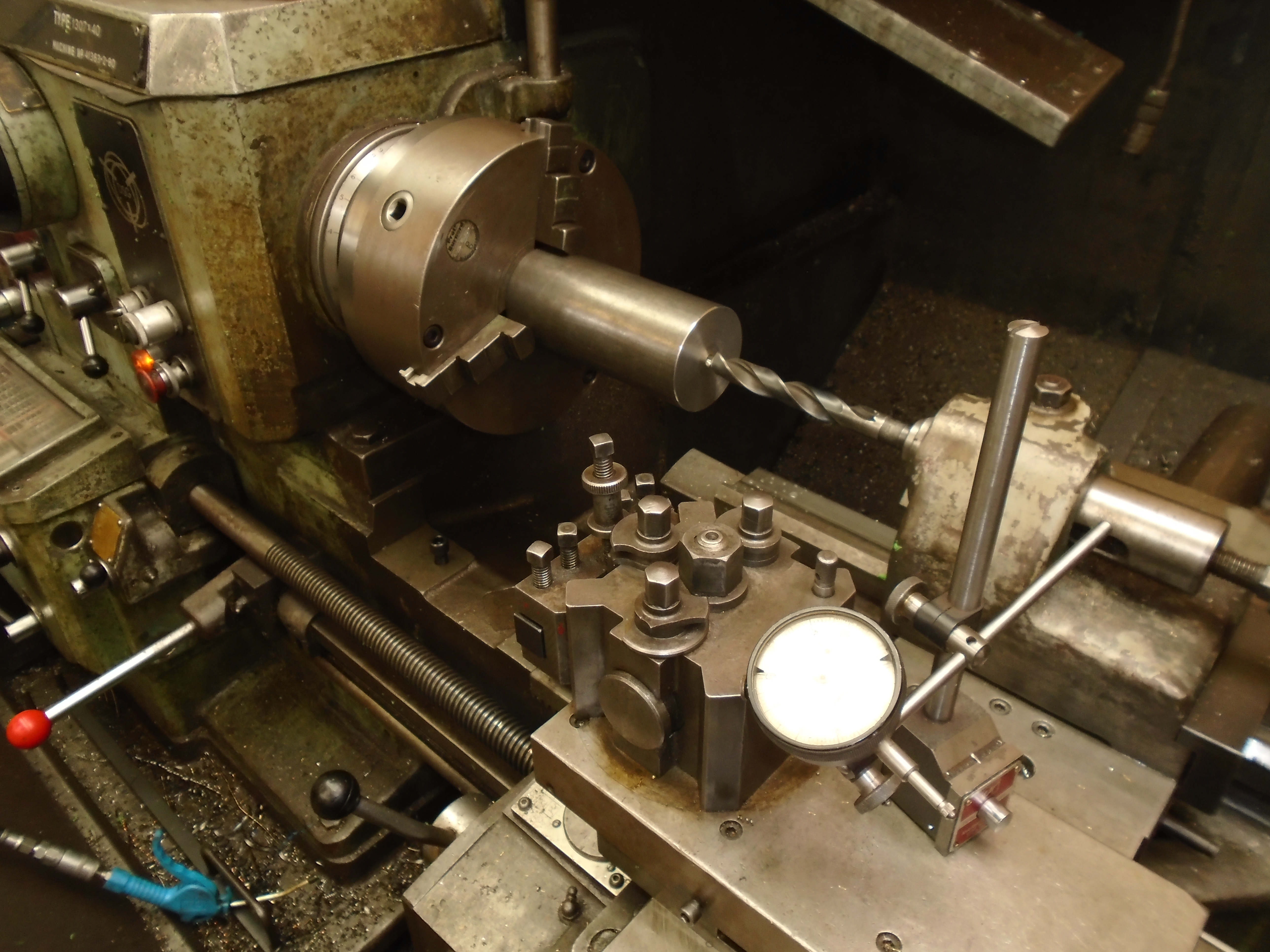

Below: The piece of steel in the chuck of our TOS lathe is part of the tooling needed for the boring job on the axle boxes, an example of which was shown above.

Below: Whilst Zoe is preparing for boring, Don is setting up the DSG lathe for manufacture of axle sleeves. It is probably easier to show how these will work in photographs, so we will cover this work in detail on the blog in coming weeks.

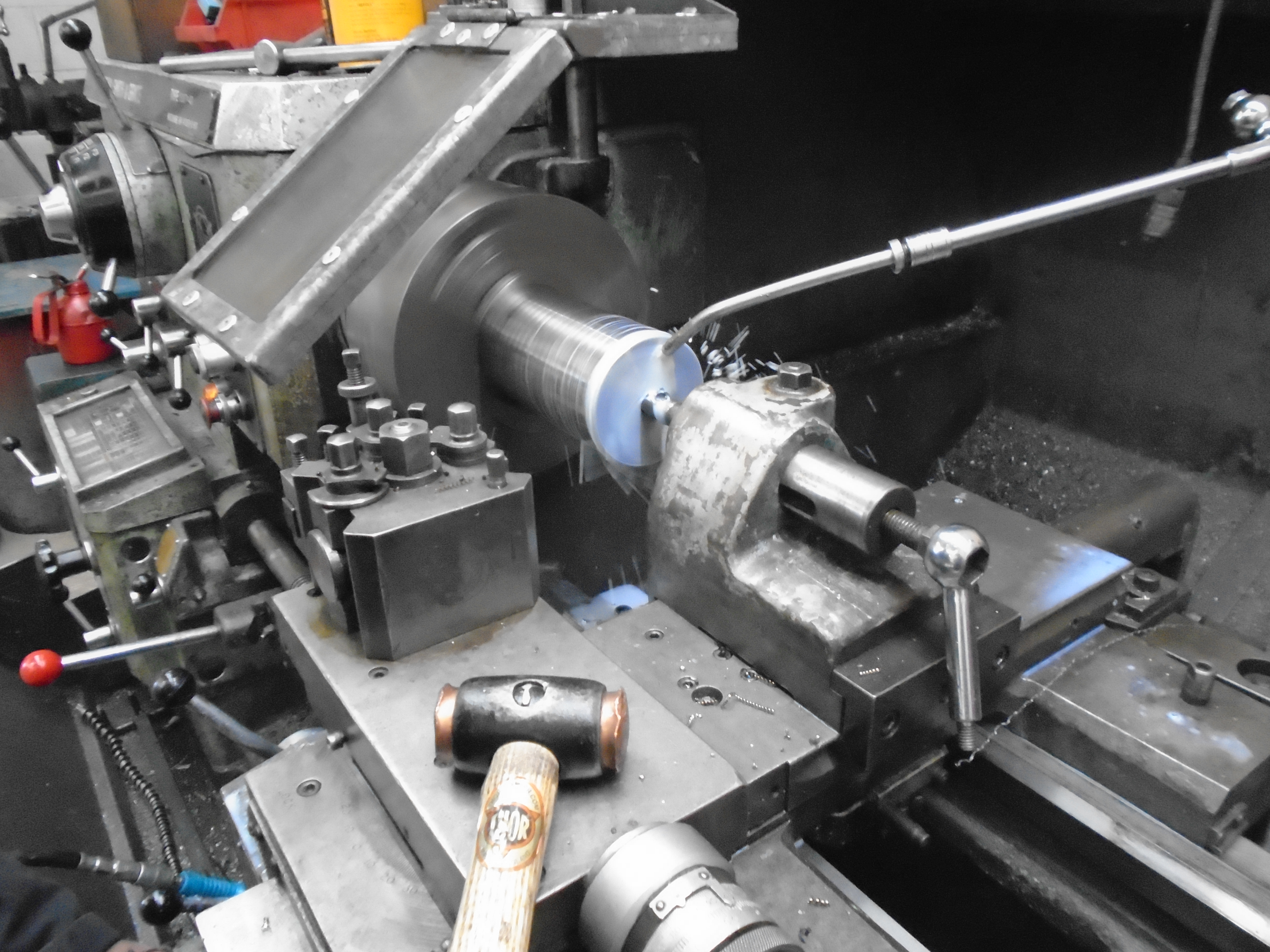

Below: Don is using the DSG lathe for this (and the whole job), the advantage here is the attachment for drilling fitted to the cross slide, meaning the drill can be fed using the power feed. A great advantage when doing 8 of them up though the drill sizes!

The taper turning attachment on the DSG will then be used to bore the internal tapers. These must correspond with the tapers on the axle journals that are something of a mystery to us and which are being eliminated, through manufacture of these sleeves. The sleeves will also correct the lack of length in the axles, which again for reasons lost to time, are too short, this causing quite pronounced problems in the axle journal and axlebox bearing interface and creating an appetite for the horseshe brasses that act to restrain the sideways thrust of the wheelsets within the bogie frames.

Due to the new demands on the machine shop, which is in near-daily use on production work like this, Don and Zoe have reactivated the flood coolant on this machine. It was used so sporadically before that such use would have been impractical.

The flash on the camera gives the appearance of the work being static in this second view.

Below: Over on the milling machine (and following on from the previous batch of photos), Zoe is about the face the back of her borer tooling in order to make it square with the shank (that has been welded to it). There will then be some holes to drill and a keyway to mill to fit this to the borer. It will then be used (with the appropriate milling cutter fitted to it) to mill the horn faces on Gateshead 10’s axleboxes

Below: The aforementioned keyway and holes being added to the boring tool.

Crosville 716

Below: The new WAV was introduced to staff and volunteers at our monthly catch-up meeting this morning, looking very impressive in the morning sunshine. Revealing it via video, the exterior and interior were displayed, and next-up we plan to make a video charting the history, restoration and completion of the bus, which I’ll put up on this blog as well as it being added to the museum’s YouTube library. This should take place later this month or early July.

Coffee Pot Running Day – Friday 11th June

Below: On Friday we held the monthly Coffee Pot running day, where the locomotive was joined by Glyder on the narrow gauge. This was primarily to carry out some shunting in connection with some fencing work that will be carried out shortly, but it also created an opportunity to pose Glyder with Crosville 716. Whilst the two probably didn’t meet, they may have shared the same postcode on occasion! Crosville ran bus services for the quarrymen at Bethesda (where the Penrhyn Quarry is located in North Wales) and I believe the buses ran into the quarry itself (the Red Lion level) though I’d be interested to learn more about this. I am fairly sure that I have seen photographs of buses in the quarry, as they replaced the use of the quarryman’s own open passenger coaches on the narrow gauge mainline to Port Penrhyn.

The opportunity to photograph the pair together was too good to miss and the juxtaposition of Glyder’s muted colours against the depth and gloss of 716 made for an appealing image, as seen here and in the header image for this post.

Below: The bus was then posed on the tramway, adjacent to the Pockerley tram shelter. Note the rather basic means of hiding the modern hand sanitiser dispenser!

Below: In the late afternoon Glyder heards back to the loco shed. In the background the Fullersite waggon awaits a delivery of coal, whilst the area to the left of and behind the loco will shortly be fenced, to allow visitors to access this area to watch narrow gauge operations. We also have a thought that, at some point in the future, we will create a sawmill in the area to the right of the track, so again this will be viewable from the new vantage point.

Coffee Pot’s next running day will be the 9th July. As usual, we will endeavour to have at least one other steam engine running in the Colliery, perhaps to show off the new fenced off viewing areas…

Tractor Repairs

Below: The Fordson N tractor that is used on site received some damage to its radiator following an incident on site, resulting in the bottom tank being smashed. This was brought to the workshop for repair, but with no spare parts available nor a solution in-house, a new tank has had to be cast. This was made using a pattern created from the broken original, which is seen in the centre of the view below. The components were reassoembled and tied together, then sand was packed by the moulder to create thickness in the walls of the tank. The resulting pattern was then moulded and cast, the result being seen at the bottom of the photo. This will now be machined before the radiator is reassembled, tested and painted.

Hi I think this T&T News should be No.16 not 15