T&I News 5 2022

After a bit of a gap, the news returns… We’ve been very busy across the museum, in all departments. It is also the time of year when we hold training days, have strategic planning workshops and on top of that have opened two new exhibits – so I apologise for the disruption to the weekly news on the transport blog!

Colliery Railway

Coffee Pot was in steam last week to enable some testing to be carried out and for it to shunt chaldron waggons onto the pit for inspection, greasing and preparation for their use in 2022. This will be more limited than before, as outlined in a previous post, but it will reduce the wear and tear on these waggons which are beginning to show their age once again. If I had a magic wand, I would attend to the wheel profiles first, then the chassis structure, but in the absence of a wand, we will continue to maintain and monitor these precious artefacts.

Below: Steam Tech Antony, assisted by volunteer Sam, carried out the work, making use of the pit in the Engine Works for the purpose.

Below: Last Saturday, Coffee Pot was out again, along with Glyder, to provide a suitable backdrop to the opening of Spainsfield Farm (open weekends only for now, due to the proximity to the haulage access road used for the wider Remaking Beamish construction project on weekdays). It was nice to hear the family who once occupied Spainsfield (in its original Weardale location) recall that they could see steam in the dale, on the Wear Valley line in the 1950s – so whilst the view is a little different, it is not without precedent! We will, at some point, have to remove some of the trees that have grown alongside the exchange sidings. This will have the double benefit of protecting our rolling stock from being scratched, and opening up the view of the railway from the north, from Spainsfield Farm.

Whilst Glyder was out, it was used to carry out some preparatory work for the Steam Gala next month.

Engineering

Below: Brake linkage components for Gateshead 10 – these have been bushed and repaired as necessary, and are currently being painted as part of the giant Meccano kit of components being prepared for reassembly onto the tram.

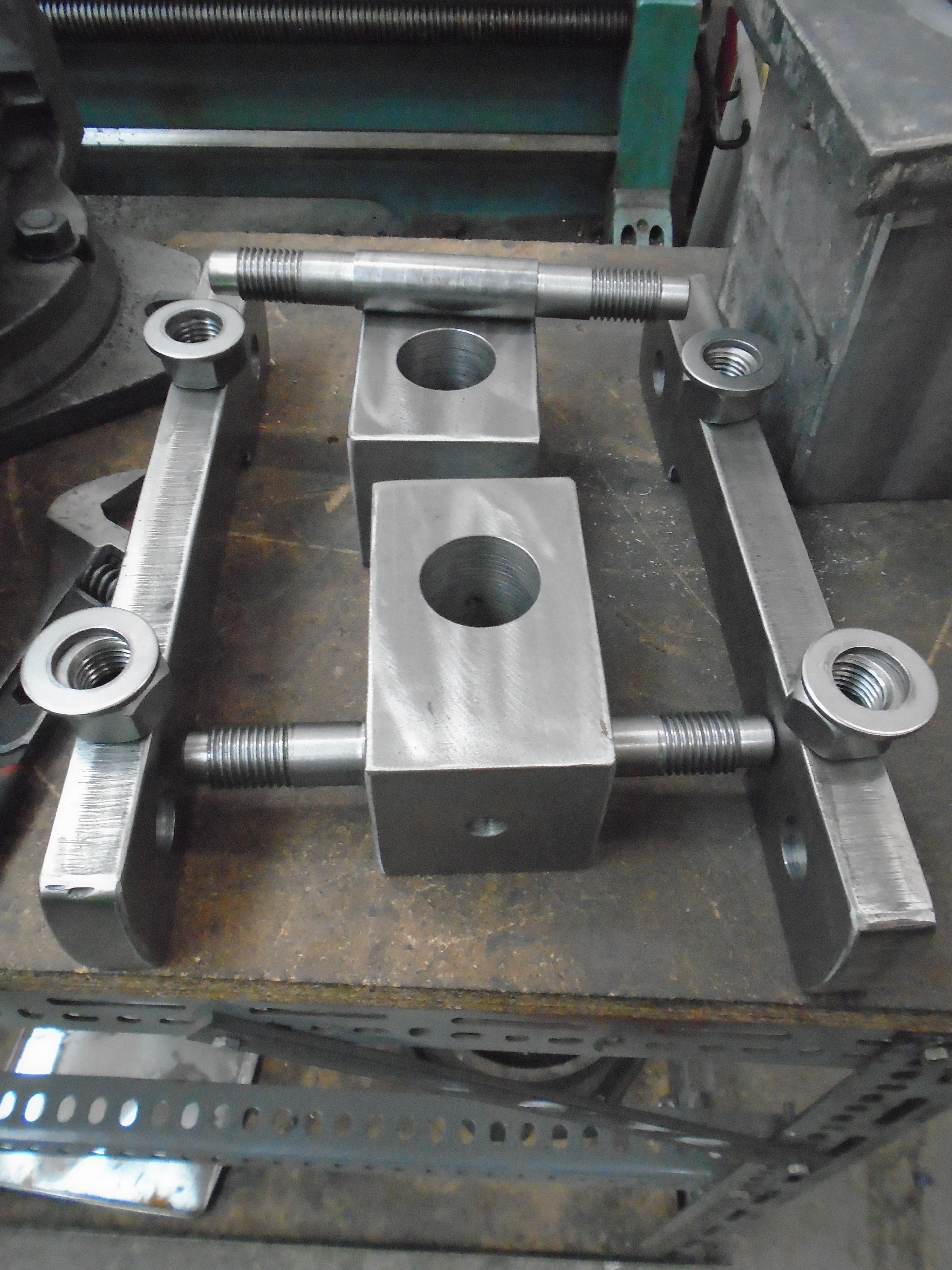

Below: Bolster links for Gateshead 10, in component form and assembled onto the bogies. These have been manufactured from new, to replace the badly worn originals.

Below: A delivery of new brake blocks for the Waggonway train, to be fitted next winter as part of an overhaul programme for the whole train.

Below: The floor structure repairs on the WAV J2007 are continuing. The frame for the rear wheel arches has been fitted and the adjacent floor structure rebuilt (renewed) – seen in the second view (which is on its side as WordPress still won’t allow editing within the programme and I didn’t have time to go out and edit it!).

Speed limit signage

For sometime now we have been undertaking a review of road signs on the tramway and roads across the museum. This includes stops, information and conditions of carriage etc. It turned out to be rather a large exercise and has stop-started over the last few years as it is never really a priority. However, on a recent visit to Lanes Foundry in Middlesbrough, and seeing they had the pattern on the wall for our cast speed signs, it reminded me that we ought to at least attempt to show what the speed limits are, if nothing else!

The opening of Spainsfield Farm has further spurred this process along, as the restricted area will be extended as far as Foulbridge Crossing (with some other speed-reducing measures in this high-footfall location), so a batch of signs were ordered.

These will reduce the speed to 5MPH at Pockerley tram stop, the Entrance, Foulbridge and the Town (Edwardian) street. Cancelling the restriction is done by further signs stating the 12MPH speed limit used at the museum more widely.

Below: Rebecca now has the first batch of signs (cast in aluminium) ready for painting (white with the edges in red and speed limit number in black – per mandatory signs of the period, and today).

Below: Matt was at the foundry to collect other castings when some of our signs were being cast – so took a sequence of photos to show the process:

We start with the pattern buried face up, the sand tamped hard around it and then set using Co2 gas. The sand contains a binder that hardens when exposed to the gas, so it is not crumbly, as a sandcastle on the beach would be.

Below: The first half of the mould box is turned over and the second half added, this is then packed with sand to cover the rear of the pattern. Passages are also put in to pour the molten metal into.

Below: The halves are then split exposing the pattern

Below: The pattern is then removed…

Below: …leaving a void within the sand into which the metal will flow.

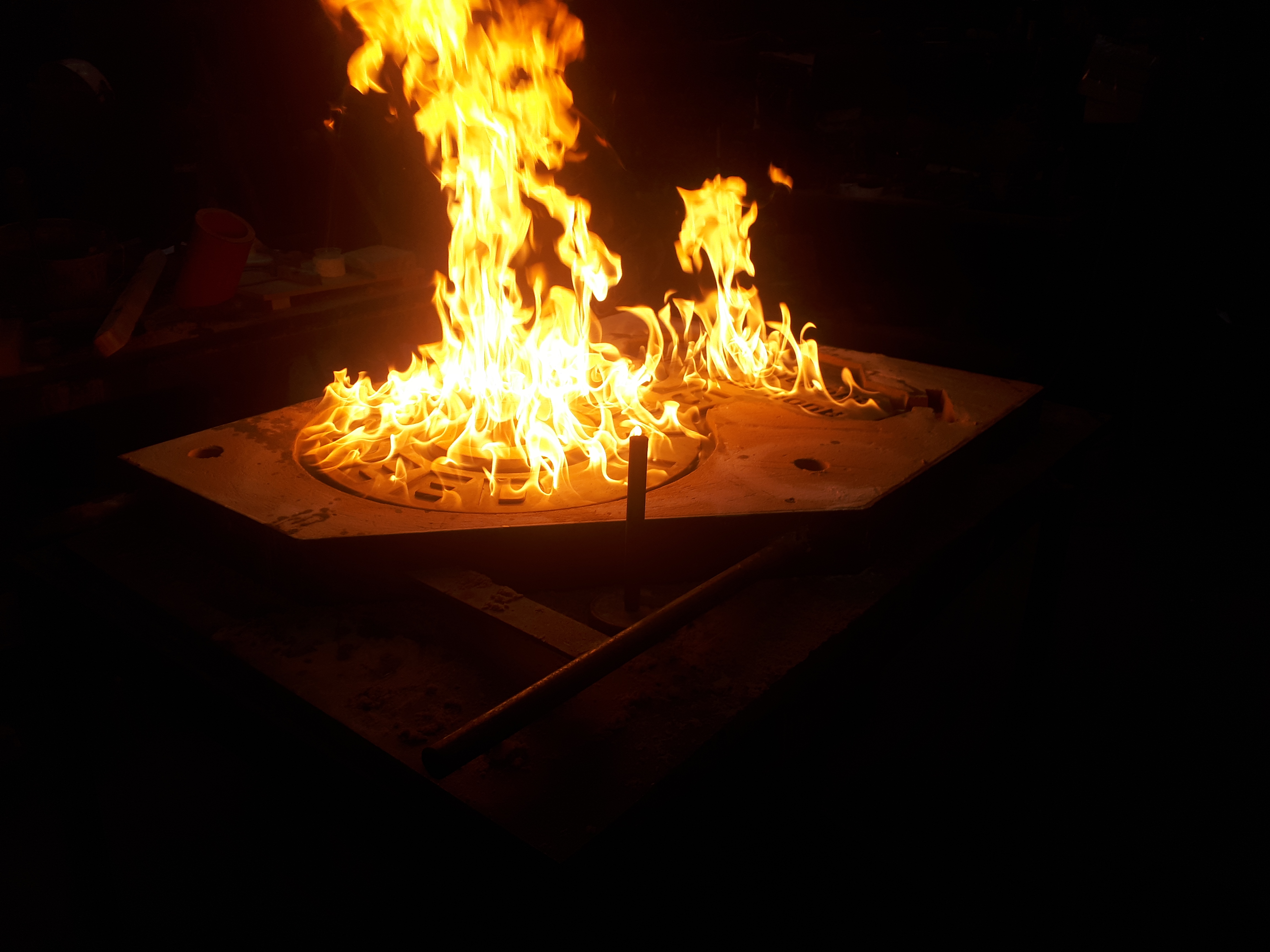

Below: In order to get a better finish on the text, the mould is coated with a modern version of black lead, which is heavily watered down with isopropyl alcohol to enable it to be spray applied. This in effect events out the sand finish to a smoother surface. The alcohol is then burnt off.

Below: With the two halves of the mould reunited, they are weighted and clamped together. The molten metal is then poured into the runner, until it levels itself in the opposing riser (the white object on the left of the mould here. Excess metal is poured into the moulds on the top of the sand to create an ingot for future melts.

Below: The rear of the sign straight out of the mould with runners and risers still attached.

Below: The front of the sign. Look out for these appearing around the museum site over coming months!

Its good to see humans at work making things with years of skill in the making.

Dont know if there is a Polite phrase for graft or weather CNC has removed it.

Credit to all.

Dave.

Why not make extra speed limit signs they may sell to visiters well you never know!