T&I News 13 2023…

There is lots to report in this post, across a variety of areas of the team’s activity. There should be more to report next week on some progress in other areas, that is now coming to fruition and will be of interest to readers – watch this space!

Dunrobin

Below: The SVR Engineering has sub-contracted the manufacture of a replacement bunker/water tank/cab section to the Ffestiniog & Welsh Highland Railway (who made the new tanks several years ago). As discussed previously, though the bunker could be patched, it was felt that this area would always be a weak spot in an otherwise very sound locomotive, so we took the view that replacing it would gives us most longevity. It is seen here upon arrival at Boston Lodge. Photo courtesy of Matt Ellis

Engineering

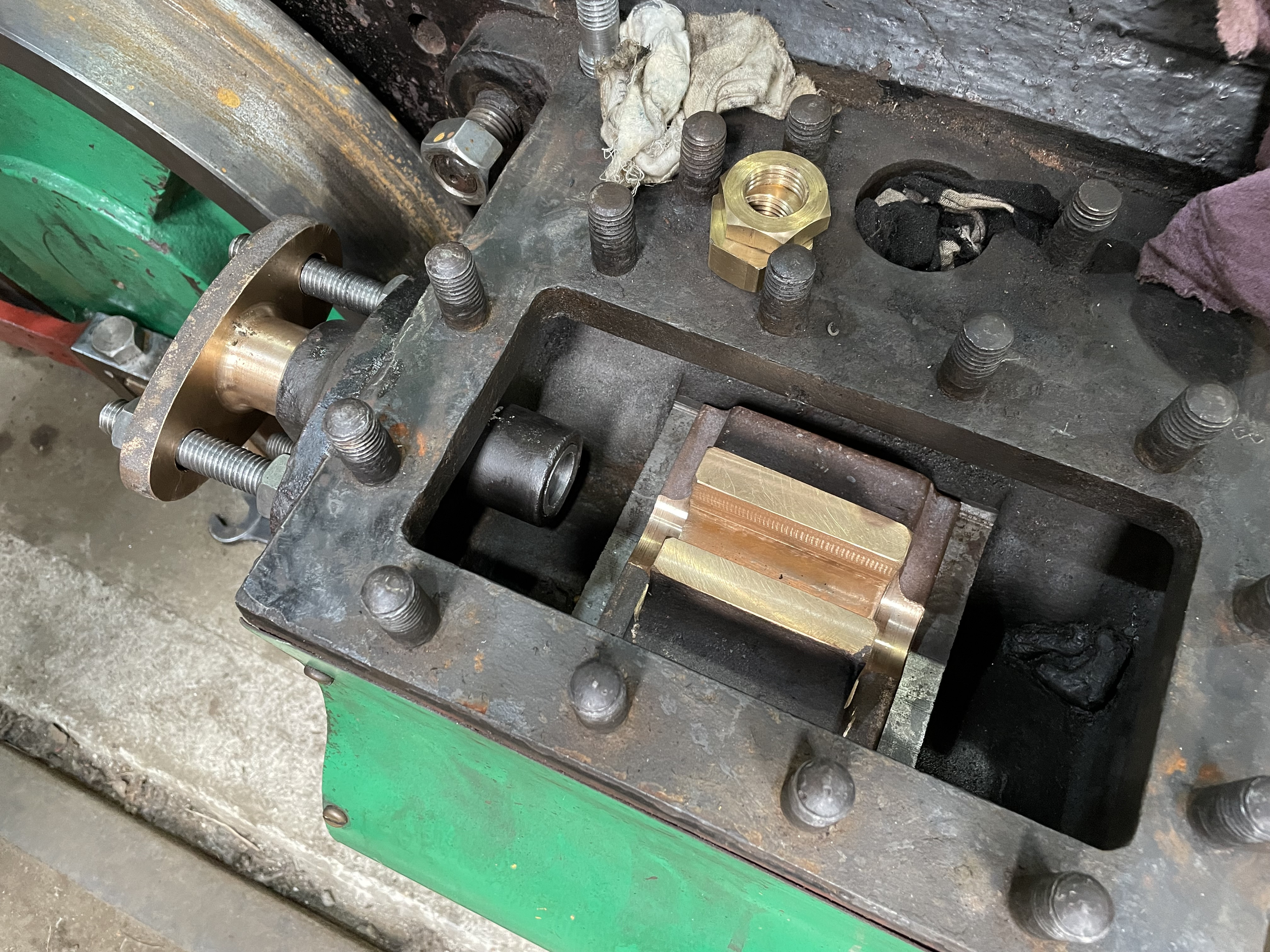

Below: Dave Young has been assembling more parts onto 721. The two cranks that convert the motion of the valve gear from inside to outside frame positions have been overhauled, with the castings bushed and bolted back into the frames, and the cranks themselves overhauled. With no effective way of lubricating these, they have had small oil pots fitted to mitigate wear of these components in the future.

Below: More new bits are being fitted – the slide valve assembly is seen here, sat on the machined slide valve face. The glands are also new, as are the bushes and nuts that can be seen here.

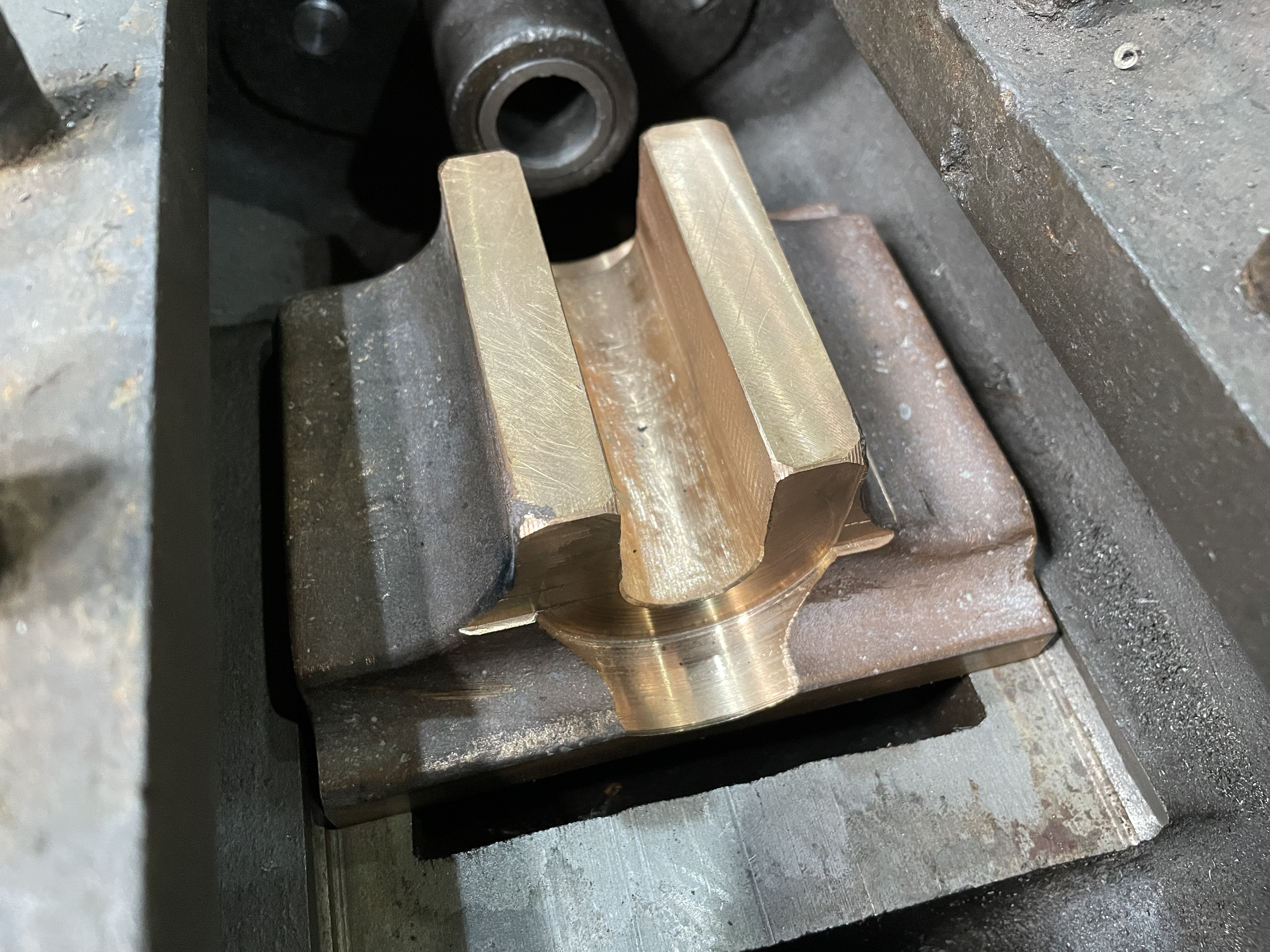

Below: A close up of the valve sat atop the valve face.

Below: The Friends of Beamish volunteers are progressing the Dodge bus restoration, with the rear axle assembly in position, as well as such items as brake pipes and the steering column. Other items are away for repair/reconditioning and the wheel centres and rims are also receiving attention (the wheel centres can be seen below the chassis). The amount of work to get to this stage should not be underestimated, with virtually every component receiving some attention to varying degrees.

Below: Gateshead 10’s second bogie has now been painted and will move to the workshop in the next few weeks. Both bogies can then have their brake gear and motors assembled, before testing in complete form.

Below: Another Friends project is the manufacture of a cab and body for the Model T Ton Truck, which is based on an example which operated locally. Progress on the cab construction can clearly be seen here.

Below: Chris and Dan have been manufacturing the engine mounts for West Riding 560, in order to mount hate Perkins P4 diesel engine into the chassis. Having measured the job, they produced a drawing for the work and have now manufactured the components to these drawings. Here is the first of the mounts, set up in the jig in readiness for welding.

Sunderland 13

Below: The North East Bus Preservation Trust’s Crossley is still with us and sees regular use – it being popular with staff and visitors alike. Here are a couple of views showing it in service (and at rest), taken last week. I wish we could keep it!

Infrastructure

Below: For sometime we’ve been monitoring the condition of the Tramway’s turnouts (points). These consist of a moving blade, switch/crossing (the bit in the middle) and a dead-mate – the bit that doesn’t move. Trams, unlike trains, run on their flange tips through pointwork, to smooth their passage when transiting it and where it would otherwise have to bridge a gap in the running edge of the rail.

Our turnouts were manufactured by Edgar-Allan (Sheffield) and are cast in Manganese Steel – which is more durable in this application. With the exception of the depot yard, none of these have seen service in pre-heritage era tramway use (though we do have some that were recovered from the Gateshead Garden Festival, and before that, the Glasgow Garden Festival tramway). They have a 1:6 angle through the crossing and have proved to be very well-suited to use at Beamish. They are all sprung, and favour the direction of operation over them, but are readily pushed aside by a tram that is trailing through. This is why you have the distinctive ‘thud-thud’ when trams are exiting loops or passing along the street, where the crossover is located.

Because of the flange-tip running, and the variety of tramcar wheelbase lengths and levels of wear, grooving occurs and increases in these locations, sometimes multiple grooves are evident where different tramcars have worn their favoured path through the crossing. Over time, these grooves can begin to influence the behaviour of the tramcar wheels, as their flanges essentially follow these new paths. There is also correlating wear on the tips of the crossings (where the wheels take the left or right-hand route) and these have often had attention in order to find an average profile, to suit the diversity of the fleet.

Over the years, some welding repairs have been carried out to restore the base profile of the crossings (effectively, to fill up the grooves), and we did investigate whether we could grind out a section and fix an insert into the crossing. David has been looking at what practical solutions can be applied, and in discussion with Chris (on the welding side), determined that a more durable weld repair would be possible. Welding rods were ordered, that are chromium alloyed for hard surfaces – specifically designed for railway/tramway track crossings.

With the rods to hand, Chris and Dan then set about preparing the crossings by grinding them back to clean metal, as seen below.

Below: With a clean surface to key into, they then built up the grooves, to restore the quantity of metal in the groove. Shelter from the sun (and rain) was provided, though the warm weather provided a useful degree of pre-heating for the rails in the area.

Below: The repair, mid way through the process, with further passes still to take place.

Below: More grinding and welding follows the initial application, as Chris and Dan integrated their repairs into the surrounding rails. The result is seen in the second image below, with the depth of the groove restored to pre-worn profile. Whilst the rods are expensive, and the work is time-consuming, the repair saves considerable expense in replacement of the crossing components (which now have to be obtained from overseas). It also enables us to rather better control the timeline, so as to minimise disruption.

David reports that the method has proved to be successful and so far two such crossings have been tackled. The cost of replacement of these components is truly eye watering, so this is an effective and economic way of extending the life of our track. David is also beginning to consider the tram depot trackwork, which is now reaching a point where it will require substantial reconstruction – it being very much second or third hand when it was first installed. We will also include changes to the geometry to extend the depot storage roads, should we ever be able to fund the extension of the depot and addition of a period facade. All of this work is at a very early stage, I should add, with no immediate plan or funding in place to carry any of this out in the near future. But it pays to be prepared!

Photos in this section courtesy of David Moseley

Around the bus depot

Below: The signs put up for the Tramway anniversary this year remain in situ, and will probably do so for a while to come, even if in a different location. We’ve a series of similar boards about the buses and bus operations, that one of the team, has been developing. These will replace the very faded (and temporary – years ago!) paper notices that are currently available for visitors to read. Once the bus signage is up, then Luke will be working on a set for the tramway (the ones shown below being somewhat thrown together by me one afternoon before the Fares Please! event in May – and people may have spotted that I forgot to include one of the trams altogether such was the rush!). It is still my intention to revise the previous tramway guide and history (and which will include the buses/trolleybuses), as and when time permits.

Below: The rather faded paper notices in the original (ex Stanley depot) Northern cabinets.

Below: Following an altercation between a bus and the roller shutter doors, which had failed to fully lift (they are on an auto-stop setting), these repeater lights have been installed, which only show green when the door is detected as being fully open. With the depot being very full, and the awkward position drivers have to look upwards to check the door, the lights provide an indicator to them that the doors have raised fully. Even slightly closed might look open, but still present a hazard. The doors at the front of the depot have adequate clearance, but not as much as we would have liked – when the building was designed, allowance had to be made for the workshop end having a taller elevation, and to make it work as a whole, the front had to at a minimum height, resulting in the lower mounting of the shutters. Possibly one of the more boring pieces of information that I’ve imparted on the blog in recent years!!!

Below: Rotherham 220 is now coming due some attention. Mechanically there is a growing list of things that Russell would like to attend to, and its appearance is also becoming quite tired. With this in mind we are looking at whether we can have it repainted this autumn, following an in-house mechanical overhaul on the transmission. Such work needs planning as the buses are now so key to the operation. Crosville 716 is similarly in need of workshop time (as the kingpins require replacement) and again, it is timing this so that the parts are available and therefore the time out of service is minimised.

Below: It is often nice to stand in the depot and reflect upon where we were in 2004 with buses (CC 297 plus B1349 on hire) and where we are now – a full depot, dedicated workshop and intensive (for a museum) daily service requiring a minimum of three vehicles. Sunderland 2 is still on our list of things to do, and commissioning this will be carried out sooner rather than later. Russell has also been working on the engine overhaul of West Riding 560, and the new engine mounts for this are at an advanced stage of production.

Recent Comments