Dunrobin – Autumn 2025 update

I thought that an update on progress with the restoration of 4085 Dunrobin was timely, with the locomotive having had its hydraulic boiler test this week, and progress made on other fronts too.

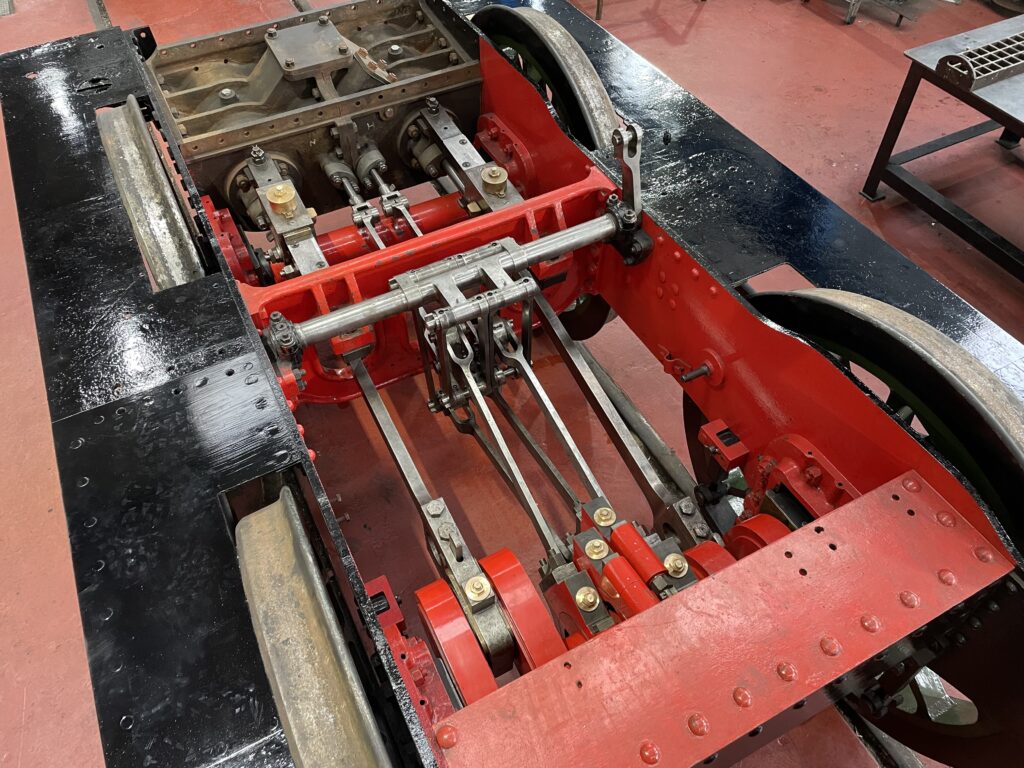

Below: The valve gear/motion has now all been overhauled and installed. Bear in mind that the sidebars, pistons and valves had not previously been used with this (new) cylinder block, so a great deal of time and care has been taken in setting up and aligning these components.

Below: Since we last saw this view, the connecting rods have now been fitted (these transmit the power from the piston rod/cylinder, to the wheels via the crank axle on this locomotive).

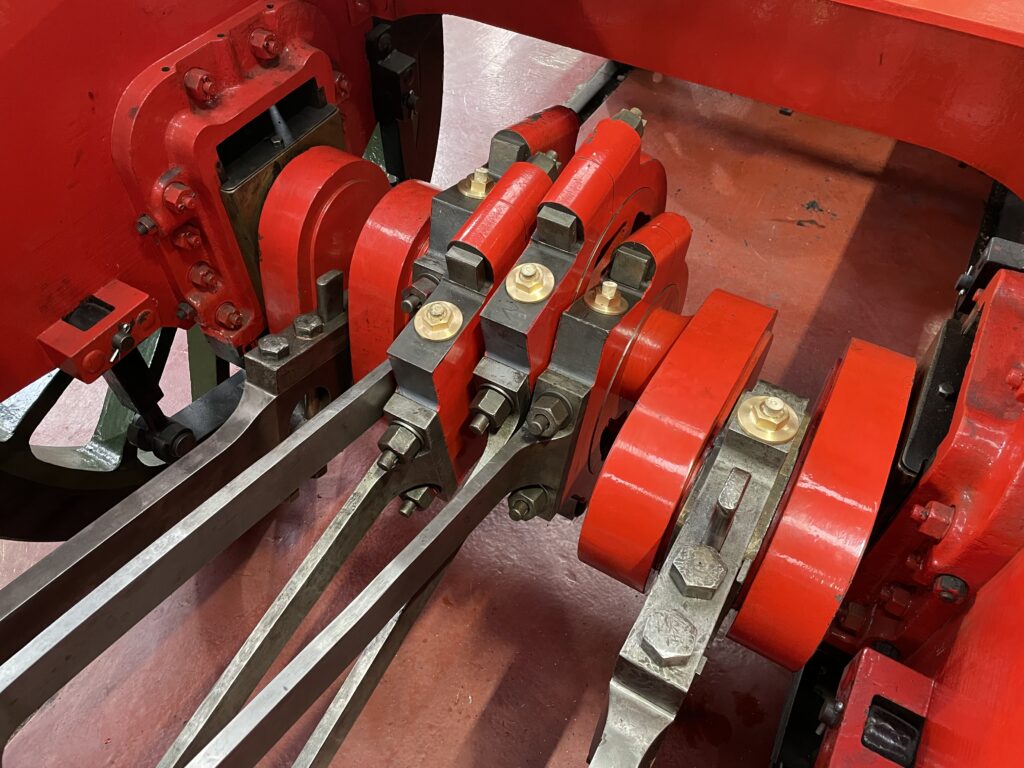

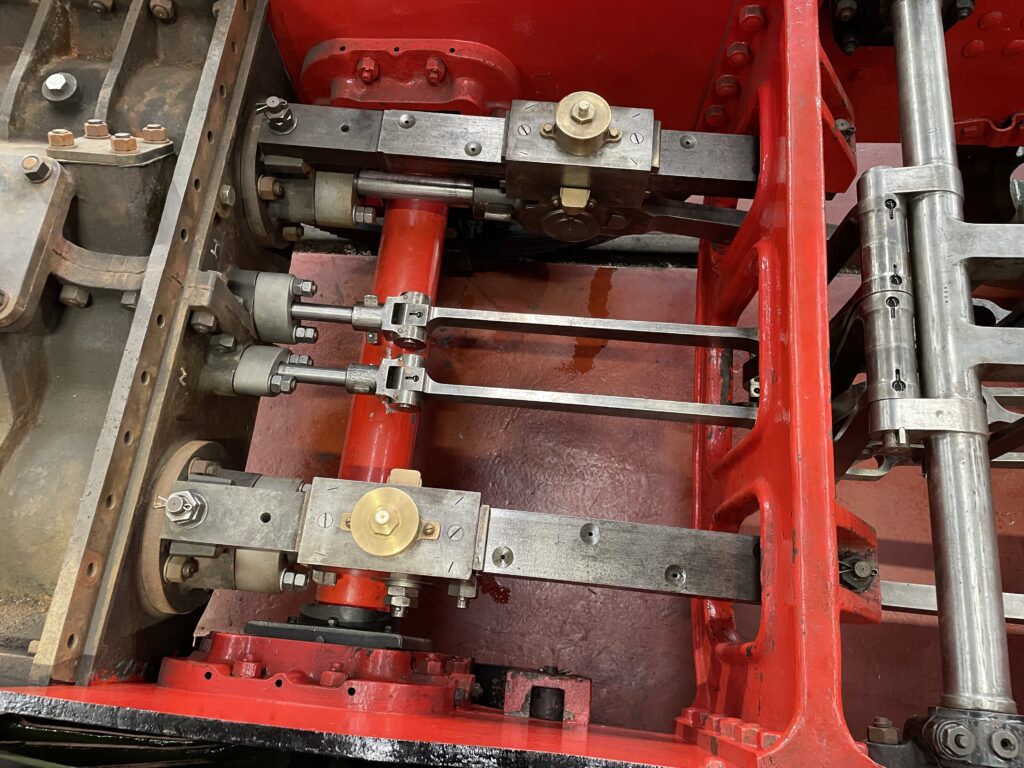

Below: A close-up view of the sidebars, crosshead and valve rods, all finally assembled onto the locomotive.

Below: The new dome, ready to be placed onto the boiler. This has been fabricated by a sub-contractor and tested. This component is hidden by the original dome cover, which is ready to be refitted when the time comes.

Below: The new smokebox with door in place. This will be attached to the boiler in due course. There is a great deal of new metal in this locomotive!

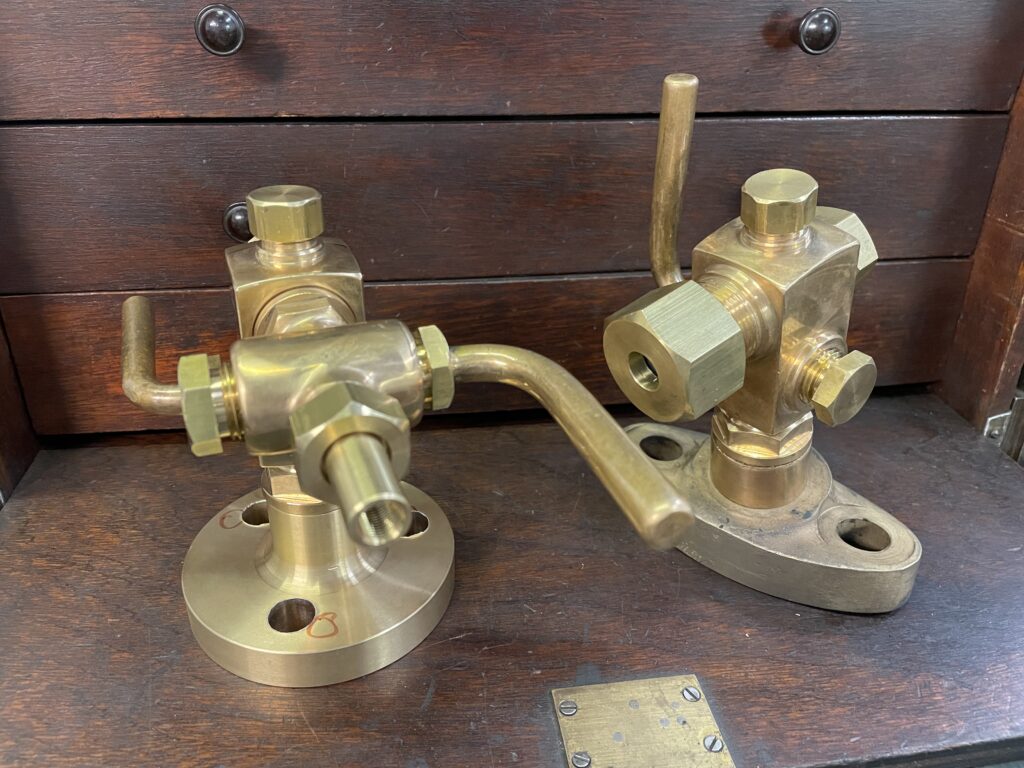

Below: Two components of the new gauge glass fittings. The originals were all intact, but had been modified in Canada, and so the whole suite of top/bottom glasses, flanges and drain cocks are being replaced.

Below: New (left) and old (right). These are bottom fittings, the top ones having a curved flange mounts to fit the radius of the firebox backhead corner.

Below: The completed boiler is filled with water and then the electric compressor pumps it up to working pressure, and then an additional third. This being a total of 200psi on Dunrobin (which has a copper firebox).

Below: The gauge, showing the pressure – this was then observed by the insurance company boiler inspector, who was looking for any decline in pressure across a 30 minute time period. With little discernable drop, the test was considered successful and the boiler will now be prepared for steam testing. This will probably entail placing it into the frames as a convenient location for the assembly of blackhead fittings to be carried out, but it will be in and out of the frames several more times before it is finally placed ready for service.

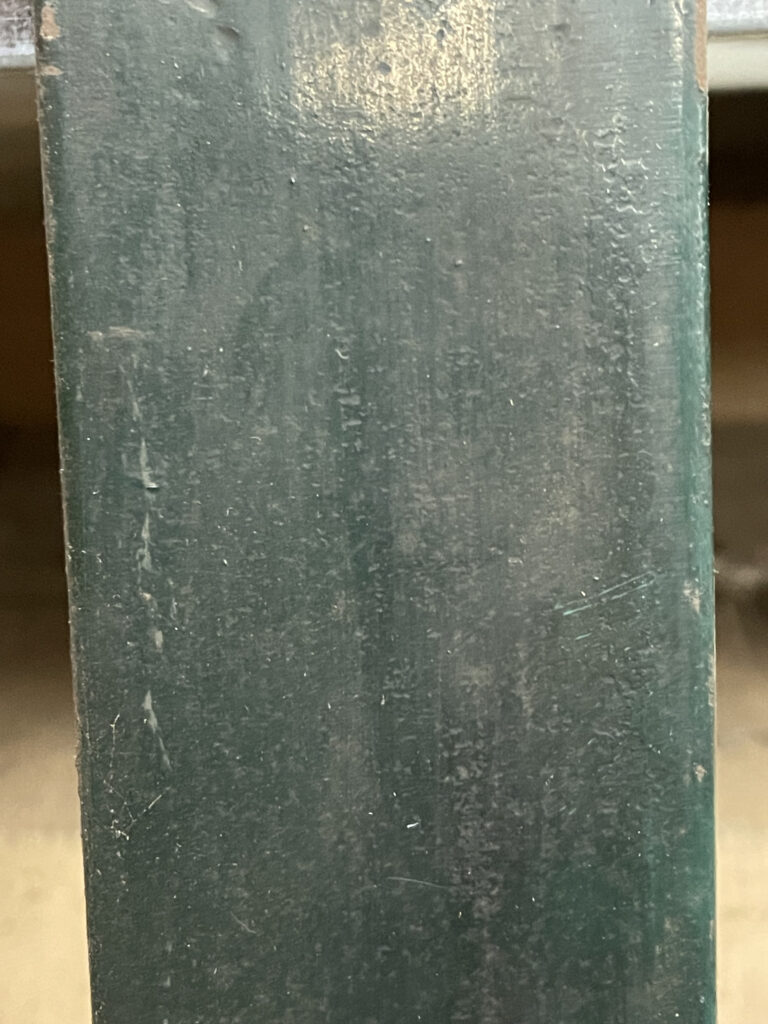

Below: A quick stocktake was also carried out, as some items will come back to Beamish for overhaul in order to help progress the restoration. An example of this is the passenger seat in the cab. This will be repaired and re-covered (the GA shows it was buttoned, so it will probably end up in dark green leathercloth). The green paint on the back of the seat backrest supports may well be original, so this is to be conserved and retained.

Below: One of the three boxes that were fitted to the underside of Dunrobin, and which contained picnic hampers (and were kept cool in these locations) to provide refreshment to footplate guests and those in the saloons alike.

As ever, we won’t speculate on a completion date for the project, though this has been much-discussed with the contractor. It is very pleasing to reach this milestone, and see so many components now ready to be attached to the locomotive as the project moves into its final phases.

Photos by Paul Jarman

Hello there, I see the restoration of Dunrobin is looking good, I can’t wait to see her on test runs at the Severn Valley Railway a few months time, that depends on the work needed to be done, such the boiler being steam tested, refitted into the frames & all put back together.