Darlington Corporation Bus Shelter Part 5

It has been quite some time since Part 4 of this story, and there has been something of a hiatus in programme for the restored bus shelter, largely as the original site upon which it was planned to be located was lost (this was to be alongside the Cinema – but the building was rotated 90 degrees and the clearance for the shelter was lost in the process). After a number of false starts which included considering its installation outside the Electrical and Toy shop, at Foulbridge, and then at the Entrance (for which the groundwork would have been very expensive), the location at Pockerley was settled upon – a popular bus stop but one that is quite exposed to the elements.

With the project programme revived, funds were allocated to creating the base and modifying the fencing on the site. Meanwhile, work on the shelter itself was required as it had not been assembled when restored. We have therefore taken the work to assemble and modify it back in-house, so as to control programme and the final costs.

Some modifications to the structure of the roof have been made, in order to ensure that it can be glazed (this was not possible with part of the ridge, in the form in which it had been assembled). This was fairly straightforward and allowed us to include a ridge decoration – something that was not immediately obvious from the photographs that we had when the project started, and so the castings for this have been purchased and modified to enable them to be secured to the structure.

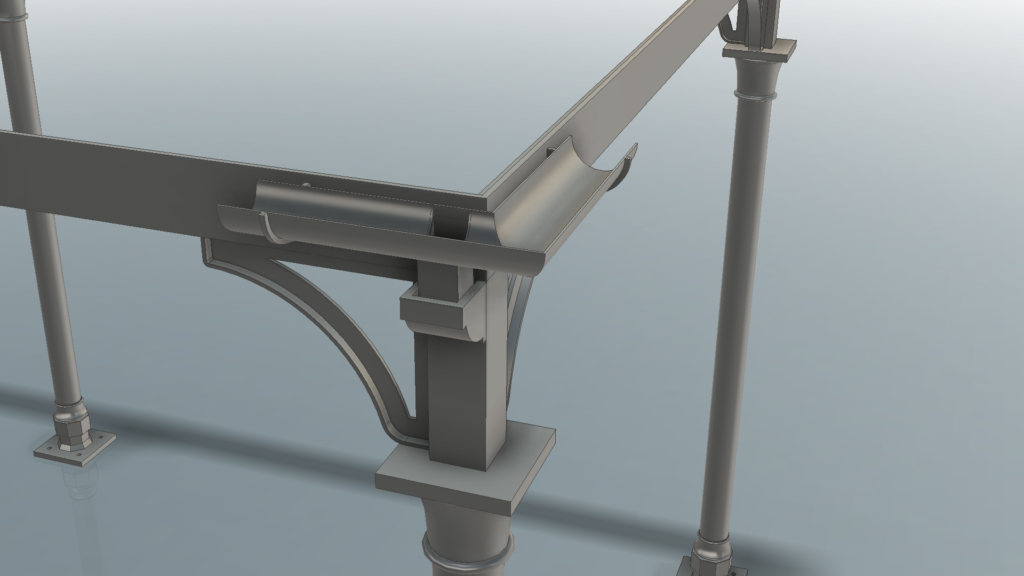

Below: The guttering was supplied in component form, and is cast iron and sits inside the brackets, which are welded to the main roof frame. The corner pieces, however, do not align with the cast hoppers that are integral to two of the legs of the shelter – the downpipe is integral to the column and a spout at its base throws the water clear of the structure.

Below: Chris has drawn up a modification that will be compatible with the original cast iron supports, an the materials are on order to allow these to be fabricated and then fit into the supplied guttering. The alternative might have been to installed external downpipes, which we weren’t keen on from a curatorial point of view.

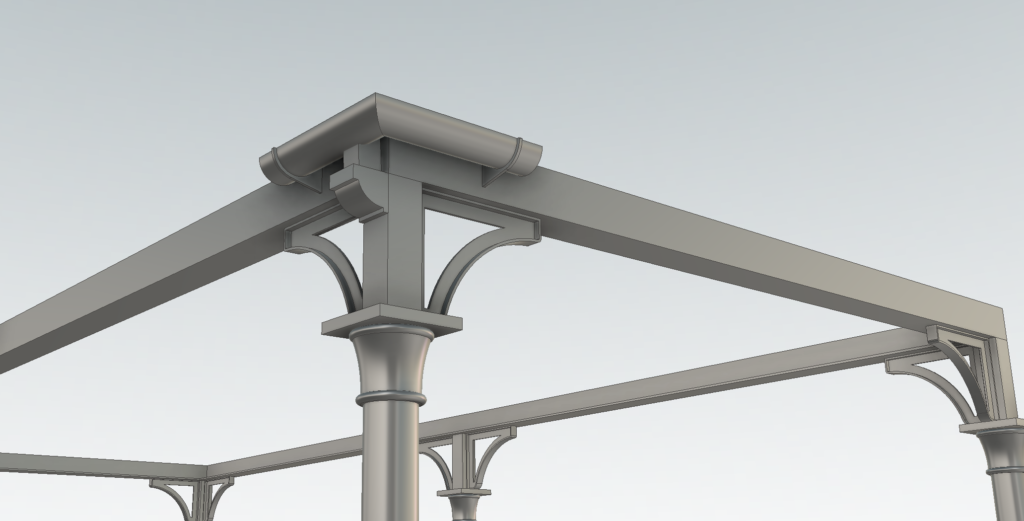

Below: An assembly view showing the guttering in relation to the columns with the integral downpipes and spouts (visible at the base of the nearest and furthest left column).

Below: The cast finial/crenellations have had to be modified so that they have tabs that fit over the ridge of the steel roof structure. The second view shows a close-up of the means of securing them in position.

Below: The completed base and fencing, pending erection of the shelter. The roof frame is slightly out of square, so Chris has accommodated this into the plans to assemble the columns onto the base and then place the roof structure onto this. This will be welded to the side brackets of the columns (which are steel) as there is very little space to fit bolts of sufficient strength. This whole section was missing when restoration started so there was nothing to copy, the frame being the strongest and most sensible way of proceeding with the restoration process.

In Part 6, the next post in this series, we should see the shelter erected and secured to the base. It will be repainted and then glazed (wired glazing was fitted to the original). We have an ex Middlesbrough bus stop sign and column which are being prepared for installation alongside the stop to complete the project.

This project has been supported by a restoration grant from the Association for Industrial Archaeology, the national society for industrial heritage, which has supported the study, preservation and presentation of industrial heritage in Britain since 1973. More information can be found at https://industrial-archaeology.org.

Photos by Chris Armstrong and Paul Jarman. Header photo courtesy of Stuart Robinson: Darlington History Facebook Group

Recent Comments