T&I News 22 2022…

A quick catch up featuring last week’s work, and a little bit of this week too, with developments on various familiar fronts progressing well.

Buses

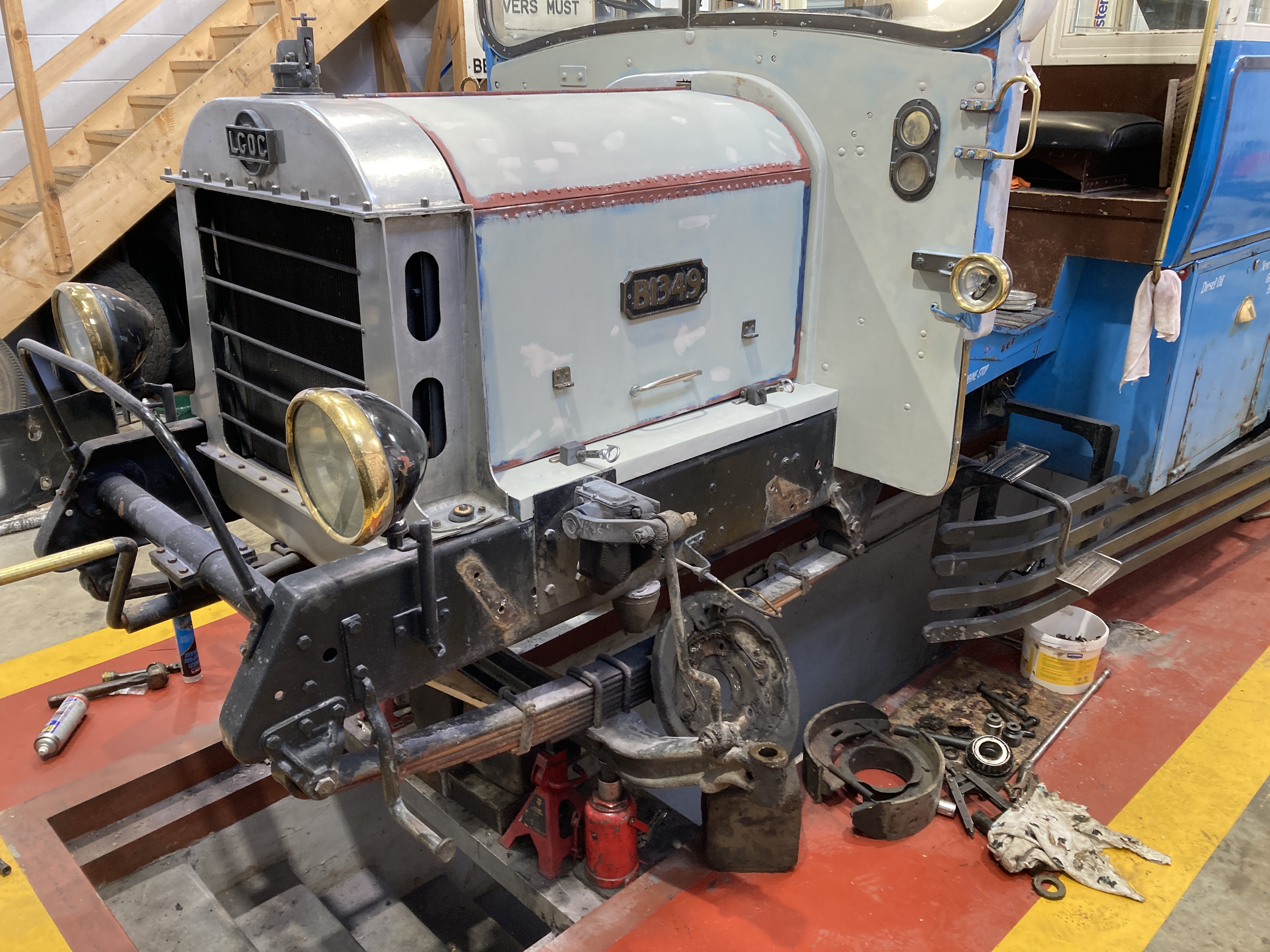

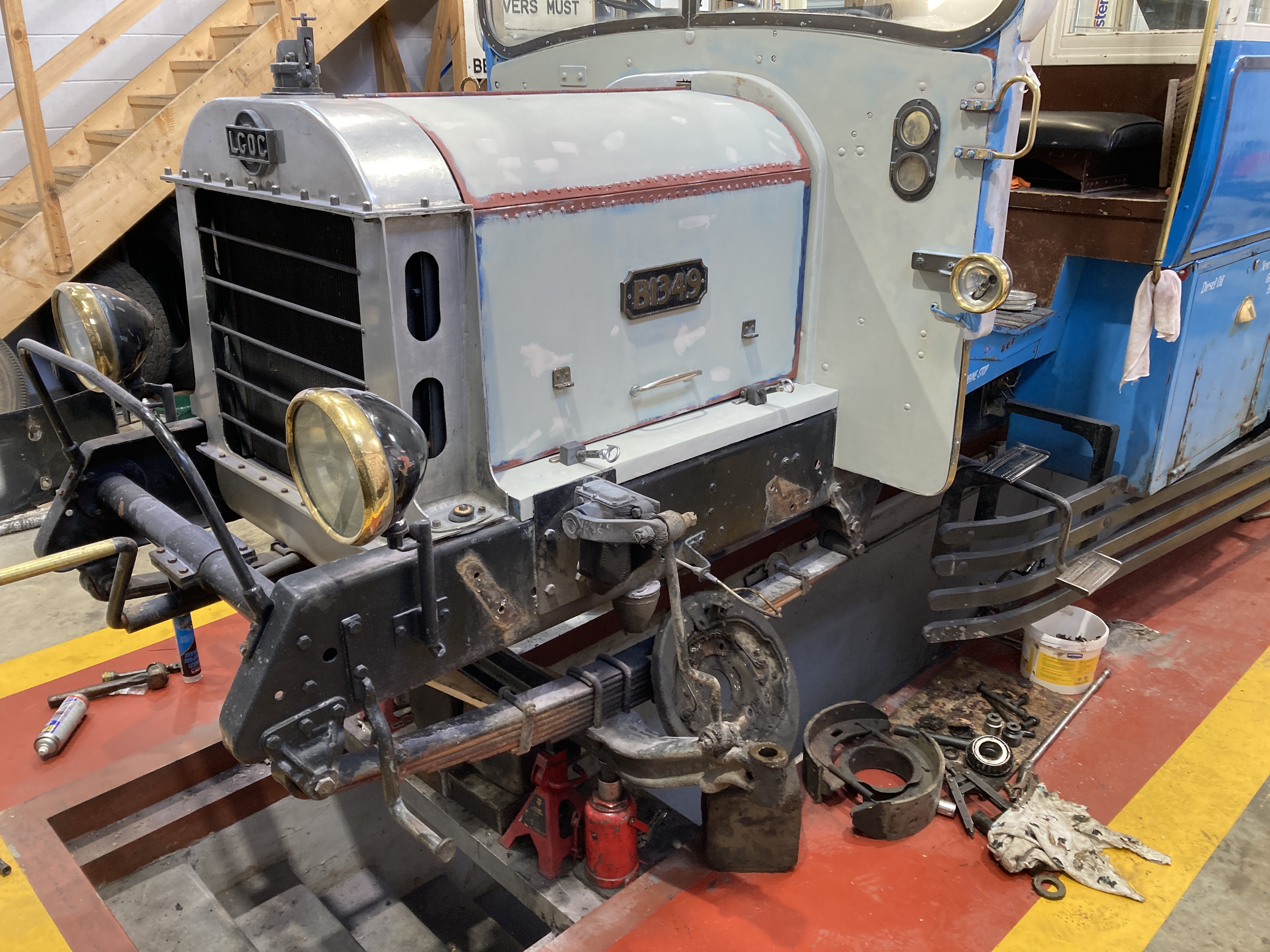

Below: The cosmetic tidying up of the front end of the B-Type continues, the deadline for this work being quite short as the bus is occupying the pit. Meanwhile we are enjoying an extended visit from Sunderland 13, which has been in service on quite a few days since it arrived for the Transport Gala at the beginning of the month. Darlington 4 is away, for completion of the work to replace the floor rails downstairs and renew the window rubbers.

Gateshead 10

Below: A considerable amount of time and effort has gone into ensuring Gateshead 10’s roof is watertight, with all of the mounted parts being sealed to the roof, and all cracks repaired and at least one patch of the canvas made. This is the work once it was primed, with the trolley planks also removed for repairs and repainting. The aim is to rapidly complete this work and install the trolleybase, so as to be able off-hire the scaffolding and then lift the tram in order to carry out work on the underframe.

Below: The roof following application of the top coat…

Below: New glass is quite hard to photograph! But there are two new panes in this view, whilst the centre windscreen is a drop light, the frame of which has been removed for treatment. Now this work has been completed, and the roof nears completion, the remaining green paintwork will disappear and be replaced with primer, undercoat and then white.

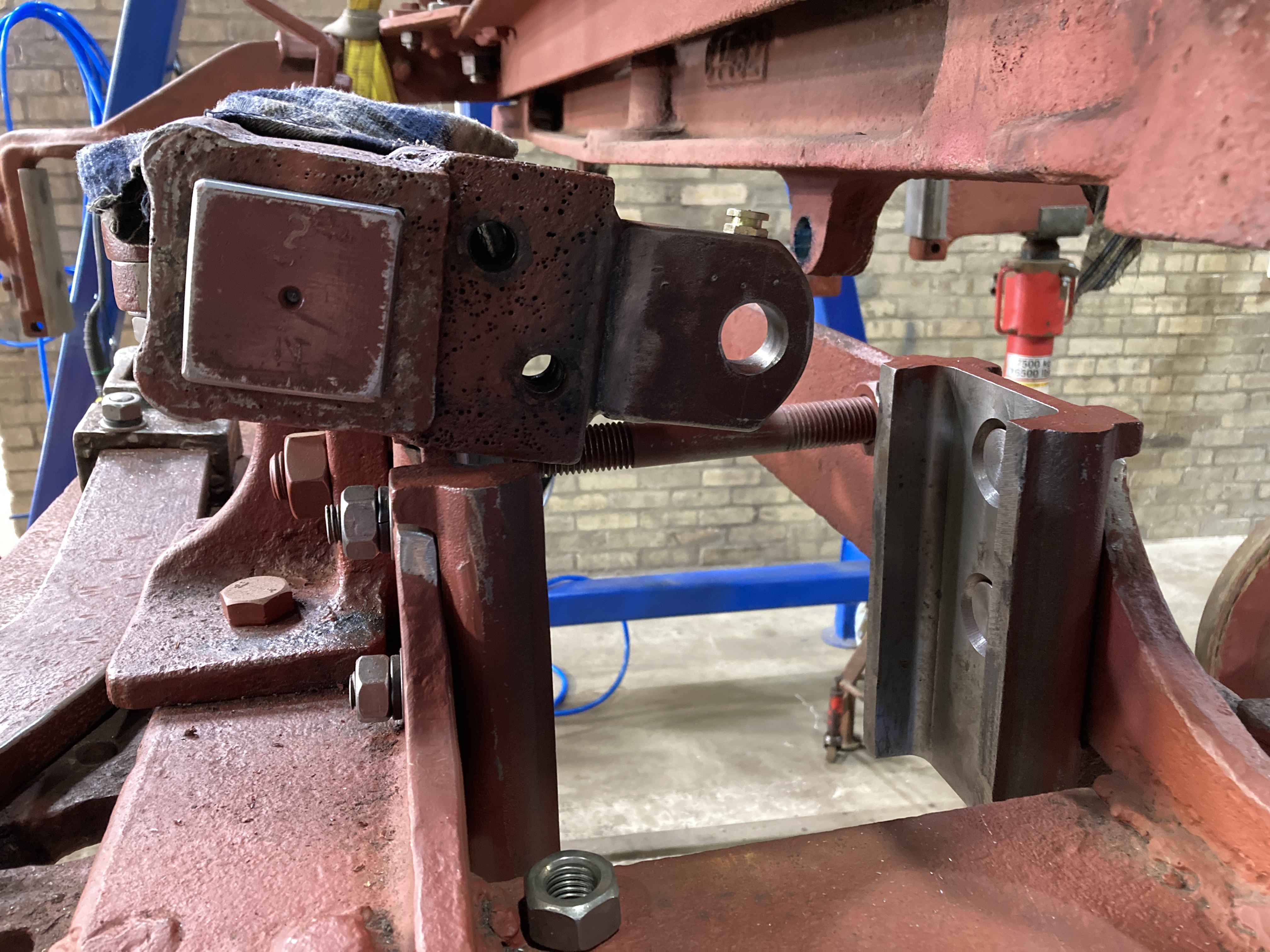

Below: One of the brake cross shafts is seen back in place, showing the means by which the track brake is forced downwards, applying the shoe to the railhead.

Miscellaneous news

Below: I was in Darlington earlier in the week, and one call was to North Bay Railway Engineering Services. They have taken delivery of the tyre blanks for Kerr Stuart 721, whose wheelsets are there for re-tyring and skimming of the journals and crankpins.

Below: Over at the Waggonway, a corner has been created in order to store domestic coal (separate to our precious stocks of Welsh steam coal).

Below: To fully contain the coal, the gaps between the stone blocks (themselves part of the Seaham Harbour coal drops structure) have bee plugged with mud, ash, sand and straw – this means the stones can easily be parted should they ever be needed again (and the idea of reconstructing the coal drops in Seaham does come round every few years or so – the cost being the main obstruction to this work ever taking place).

Hi

I was interested to read about No 10 and its partial glazing.

Do you need to reglaze windows to be either safety or laminated glass and how if installed do you know which?

Going back over the last few engineering challenges do you use a datum point from a fixed point or the best guess from how the original was produced so the bogie sits true.

All the best.

Dave

The detail (as shown with the former Seaham Harbour coal drop stones) at Beamish confirms the fact that every visit reveals ‘something new’.