T&I News 11 2023…

Thank you all of those who have responded regarding the future direction of this blog. For now, at least, and probably for the foreseeable future, I shall continue to post in this format, though posts may be less-frequent and more focussed. That said, there is plenty to report, so I shall give a quick roundup of the most recent activities…

Engineering

Below: The recent work on Puffing Billy revealed that considerable accumulation of ash was inhibiting inspection of the underside of the locomotive, and contributing generally to the tired appearance of the locomotive beneath the frames. The ash comes from the aperture beneath the fire grate and firehole door, and so to assist in disposal of the ash and direct this to the side of the locomotive, this ash tray has been made in the fabrication shop, to fit precisely onto the locomotive when disposing of the ash. It can be placed to empty either side of the track, as illustrated here.

Below: The fabrication show have also made a new door protector for 1219, the old and new being shown here, along with the drawing that was produced for the job.

Below: This view shows the new protector in position.

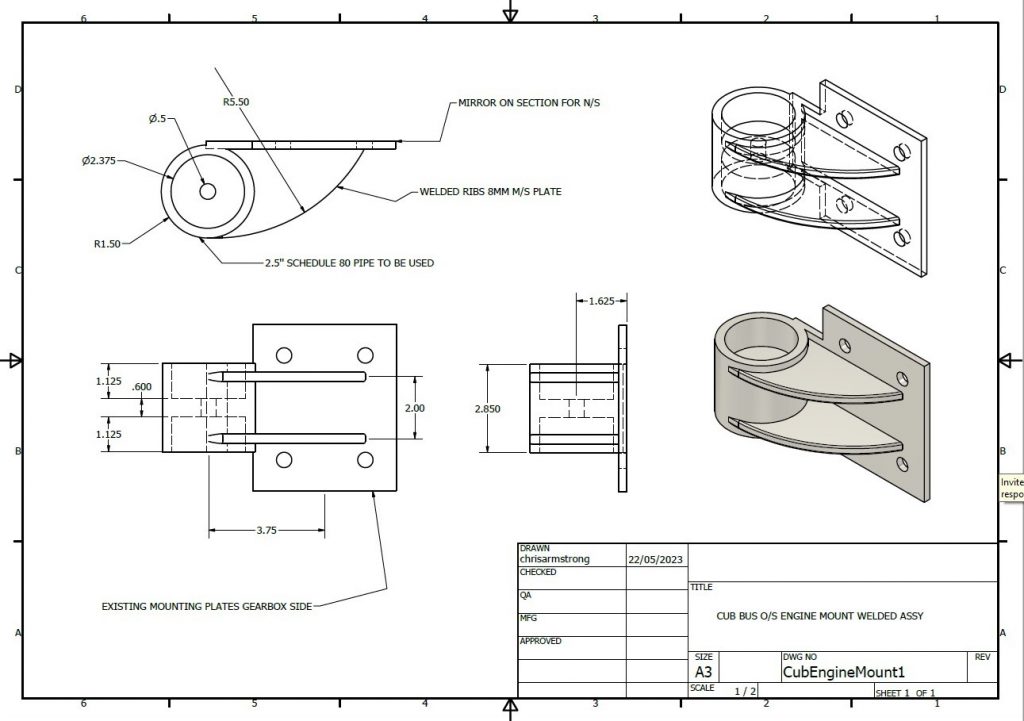

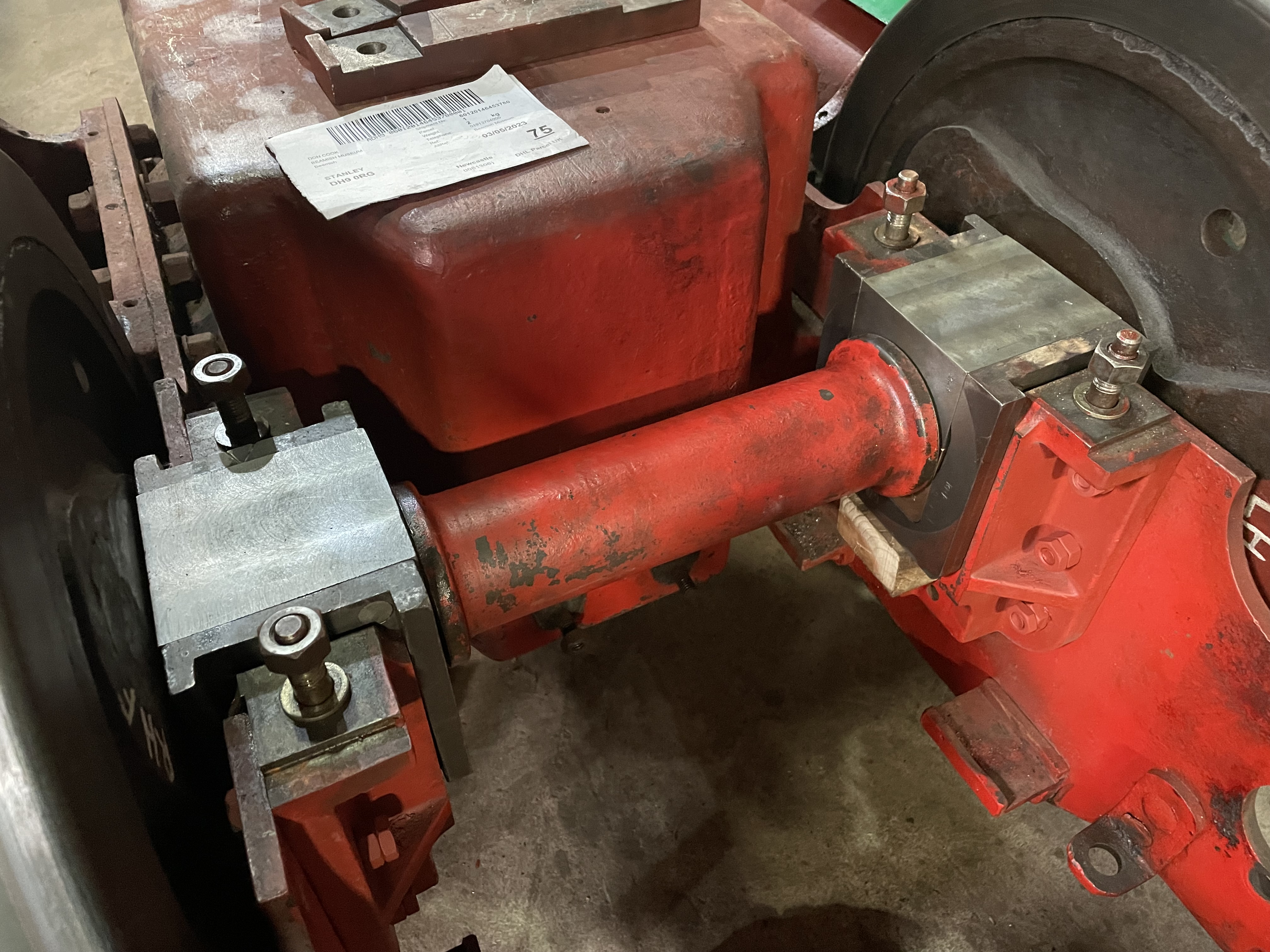

Below: The next job for Chris and Daniel in the fabrication shop is the manufacture of new engine mounts for West Riding 560, which is being adapted to receive a Perkins P4 diesel engine in place of the Leyland diesel that came with it. We had this engine in store, and it is fairly easy to obtain spare parts (it is the same as that fitted to CC-297 as well). For work like this, the team are also producing drawings of the work, to enable this to be kept as part of the technical record for the vehicle.

Below: I missed including this the other week – new span wires, made up into assemblies for installation as part of the programme of overhead line maintenance on the tramway.

Below: Dave continues with the overhaul of 721’s axleboxes, all four of which have been trial fitted, as seen here. We will have to assess the condition of the springs, before final assembly (as well as paint the frames), but this is excellent progress on this project.

Transport Operations

Below: Last weekend we had a YouTube vlogger with us, to review his driving experience of Coffee Pot No.1 – look out for this appearing on the platform in due course… It was a nice chance to have No.1 in steam too.

May Bank Holiday (the last one in the month)

Below: When I was on my way to the office this morning, I was struck by the apparent congestion around the bus and tram depot yard, as all but one serviceable vehicles were prepared for service, including seven buses and three trams. This must rate as one of the busiest heritage transport operations in the UK. In addition to the vehicles shown here, the Waggonway was also in operation. Comforting steps towards the eventual return to pre-COVID-19 days and a breadth of operations across the museum.

Here buses are washed before entering service for the day. Both WAVs are in traffic, with the expectation of a large number of visitors over the weekend and with positive weather forecasts hoepfully encouraging footfall through the gates.

Below: Three trams are in service, with 196 as spare and 264 waiting for its repaired motor to be fitted (which is now back on site).

Below: NGTC CC-297 (usually known as the D-Type, but which should really be addressed by the fleet number) and SCT 13 are seen following washing and preparation for traffic.

Below: Two colliery buses are available today, as well as the three double deckers and two WAVs.

Below: Just to put a full-stop on this item, here is the bus depot, empty of all of the regular running fleet. The SOS (left) has been commissioned for passenger operation, though is used sparingly, whilst Sunderland 2 awaits commissioning for demonstration use, so that we can assess what is required to take it forward to eventual passenger operation at the museum.

Dunrobin

Below: The SVR team reports that the alignment of the new cylinder block is complete and that axle alignment has also been concluded. The overhauled crossheads are seen here (ready for fitting once the slidebars have been aligned).

Below: The axleboxes are now complete and are seen here fitted to the trailing coupled wheelset (they are the items just behind the rear face of each of the wheels). The completed bogie sits in front. The workshop hopes to re-wheel Dunrobin shortly, which will be a significant moment in the project. We have also decided to have the bunker and rear-cab section replaced too. The original is not in great shape and given the level of renewal elsewhere on the locomotive, there is little sense in retaining something that would give cause to need replacement during the working life of the locomotive.

Photos above courtesy of Duncan Ballard

I visited Beamish last Saturday and rode on the 3 trams in service and the 3 buses also rode behind Puffin Billy.

I went inside the loco shed (pit village) the info boards that were up for the steam fair were gone (Shame hope they return soon ) on malable no5 for some time loco has 1 name plate on did it only ever have 1 plate? and how about painting a no5 on the front buffer beam (yellow or gold would be my choice)

Still had a great day.

Gary

Hi Gary

The info boards will be back – they are having the glass in the frames replaced so as to be more durable. There will also be more for the buses and trams soon too. Malleable only has the plate on the most visible side, which is a replica, fitted a few years ago. The number is on the nameplate and as far as I can tell, it didn’t have another one elsewhere (which is quite common for industrial locomotives).

Best wishes

Paul

I couldn’t find the best post to ask this on, so have gone with the latest. I have a few questions about Rowley Station….

– Where is the weigh hut/cabin originally from? It looks like those on the Alnwick – Cornhill branch.

– Where is the NER yard crane originally from?

– Is Rowley painted in LNER brown/creme rather than NER chocolate/buff? The brown looks considerably less “red” than say Goathland on the NYMR. The signal box nameboards also appear to be the LNER wooden type that went on the ends rather than the NER enamel which went on the front.

Looking forward to seeing locomotive movements at Rowley in the near future. Maybe No.876 will pay a few visits when she returns to steam?

Many thanks and really enjoying the blog post updates.

Hi Ian

The weighbridge and hut came from Glanton, on the Alnwick – Cornhill branch, as you suspected. The crane came to us from the Tees & Hartlepool Port Authority. The colour scheme is based on NER colour charts reproduced by the NERA – where the colours were described (and very much appear to be) chocolate and cream. Whence the browner appearance of these. We have enamel signs for the signalbox, but these require restoration.

Nothing due to move at Rowley until 2024/5 when Dunrobin is ready and the long to-do list of jobs have been tackled. 876 is due to visit us as part of the funding it received, though this will be a short-term visit rather than a lengthy one, and won’t be for a little while yet!

I’m glad that you enjoy the blog!

Best wishes

Paul

Hi Paul thanks for the info.

Gary