T&I News Week 48 2015…

A more diverse range of news for this report – I am struggling to keep the posts up to date with the work actually taking place!

RHEC

Below: The Model T Ford programme continues to see the dismantling of the T van chassis alongside construction of its new flatbed body. John is leading the mechanical charge, and as can be seen, has found much to occupy him! The bodywork has also been flatted and undercoated – this will be painted olive green/khaki once I’ve identified the correct/most likely shade to use for the vehicle.

Below: Sheffield 264 is heading towards test running this week, all being well. Here is a view of the top deck just before the light fittings were installed, showing the re-varnished and re-painted seats, floors and side panels. There will be some further varnishing on the ceiling panels to protect the rather lovely transfers there.

Below: The tram is more or less electrically complete and being tested to enable energisation later in the week. Here is a view beneath the seats downstairs showing the various fuses, protective devices and dewirement buzzer assembly following refurbishment and installation.

Below: Matt B is seen working on the framework for the S&D open coach from the Waggonway. The design for the roof has been agreed and the refurbishment of the bodywork is well advanced.

Morris Commercial

Below: An example of the detailed restoration work undertaken on the Morris and not anticipated when this project started – these are the handbrake drop arms showing new bushes fitted into the bored out cast arms. Cumulative attention to these sort of components should result in a nice ‘tight’ vehicle and a noticeable difference to how it felt to drive before the work started… It would be fair to say that so much more work has been required that we might have started expecting to carry out a full rebuild rather than the heavy overhaul the project has become. However, the result should be very worthwhile as the lorry will be far more pleasant to drive and good for years to come.

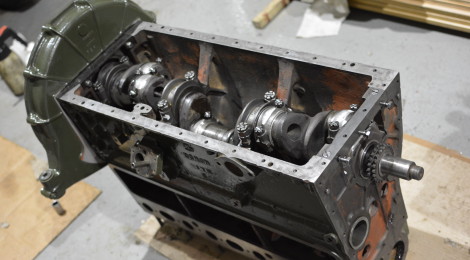

Below: The engine reassembly is now well advanced and completion of the running gear is not too far away now…

Leyland Cub Crosville 716

Below: There should be some news showing great progress on the outward appearance of the Cub soon, but meanwhile these views show just a fraction of the myriad details that go into a full ‘nut & bolt’ restoration. Here we see the beginning of the rear brake assembly. The slave cylinder dominates the view at the top of this view, taken before the shoes etc. were fitted.

Below: A legion of detail components go into the brake assembly – these cams retain the brake shoes within the drum and have all been reclaimed and refurbished, or made from scratch to the original design.

Below: The re-lined shoes are fitted up and the various retainers fitted – note this is the rear axle so the hub is fitted with the double wheel arrangement here.

Below: More refurbished parts from this Cub and various other spares we’ve been able to purchase. Seb Marshall has shaken the ‘Cub tree’ hard and produced numerous components for this and future restorations. These items are parts of the prop-shafts, all restored or renewed as required.

Dunrobin

Below: The SVR boilersmiths have been working on 4085’s boiler in recent weeks, making a start on bushing the stay holes in the outer wrapper. Here is a hole following removal of the original stay and before opening out for bushing.

Below: An oversize hole is created and tapped ready for bushing.

Below: A bush inserted, note the smaller internal diameter hole into which the stay itself will be screwed.

Below: A view that gives some idea of the scale of this job and its repetitive nature! This was an LMS practice in restoring stay hole sizes, so is quite appropriate to Dunrobin’s former sphere of operation.

Below: The front angle ring, following machining and awaiting fitting, drilling and riveting to the barrel. Once that work is completed the barrel will be fitted to the firebox, completing the major structure of the boiler.

Recent Comments