T&I News 12 2019…

This week we have another eclectic mixture of projects, all of which have been progressing within the Regional Heritage Engineering Centre (RHEC) or which will become part of the facility (namely the new vehicle workshop within the bus depot).

RHEC

Below: We start with a sequence of photos showing the transformation of the fairground packing truck, which has been enhanced to provide better storage for the gallopers’ horses. What started as a quick improvement has now become a rather more impressive piece of work – Rebecca, the RHEC painter, using tracings from the gallopers rounding boards to reproduce the signwriting on the side of the vehicle. The rest of the RHEC team has repaired and painted the truck, fitted a permanent roof and improved the interior as well as manufacturing steps for fairground staff to safely access the truck. The plan is to position this truck, and one other, so as to screen the gallopers and fairground area from the wind, which blows hard across the events field. In due course, I recall, a small wooded area is to be planted to provide a similar effect, but trees take time to grow (and even longer to plant sometimes!) so the trucks will hopefully provide some shelter in the meantime.

Below: A mixture of staff and contract work has seen the re-skinned Daimler bus panels repainted, signwritten and lined. Large parts of teh rest of the bus have received attention to paintwork, as have the top-deck seats. It awaits fitting of the re-tyred solid-tyred wheels before an entry into service soon.

Below: The team have also been manufacturing firebar patterns for Glyder, seen here following painting and in readiness to go to the foundry for the iron castings to be made.

Narrow Gauge

Below: Work on Glyder’s boiler overhaul is now all-but complete. The boiler was steam tested for our own purposes before a formal steam test with the insurance company inspector on Monday, which was passed. The first time that it has been in steam since the mid 1960s, and in steam in County Durham since the 1930s…

Below: With the test completed and boiler cooled down, a start was made on preparing it for installation into the frames. The firebox cladding was painted as this will be obscured by the bunkers, but visible sections and also the boiler cladding will be painted to harmonise with the original paintwork which is being retained on the cab etc. The cloning of the German Orenstein & Koppel designs has become very clear during this process – with everything being pretty accessible – not always something we find with steam locomotives!

Below: These views show the certified boiler being lifted into the frames (or rather, onto the frames), in readiness for final assembly to commence. Care is being taken to retain the industrial paint finish and knocks and bumps so evident in photographs of Glyder when working at Penrhyn Quarry.

Below: By Friday the boiler’s wooden lagging and steel cladding had been fitted. This will be rubbed down ready for application of the black paint finish.

Tramway

Below: Oporto 65 has been outside for a steam-clean in readiness for lifting off it’s truck so that this can be reversed (at a recent point in history it was detached for storage then replaced for transit in the most accessible way). The Beamish Tramway Group continue to work on components for 65, with the staff now fitting in jobs in and around the rest of the fleet (the work on Gateshead 10 now being in the hands of the machine stop staff, once their current work is complete). A re-wire is on the cards for 65, and the controllers have been overhauled. A previous member of the staff then used these as a source of spares for 196 to save his time, but this has been remedied on all counts and the new staff working on the tramcar maintenance are engaged with the recommissioning of 65.

65 is seen drying in the sunshine, with fellow Oporto car, 196, acting as shunter. The plan is to get 65 back into operation, then assess the truck/motor ahead of overhaul plus attend to cosmetics and the paintwork.

Bus Depot

Below: Work on the bus depot is advancing well, with work continuing on the internal wall structure in readiness for casting the floor slabs. The roof cladding is also being installed – a grey cement based material reminiscent in corrugated form. The building frame has been entirely cocooned in scaffolding in order to allow this work, and the brick outer walls and pillers, to be constructed.

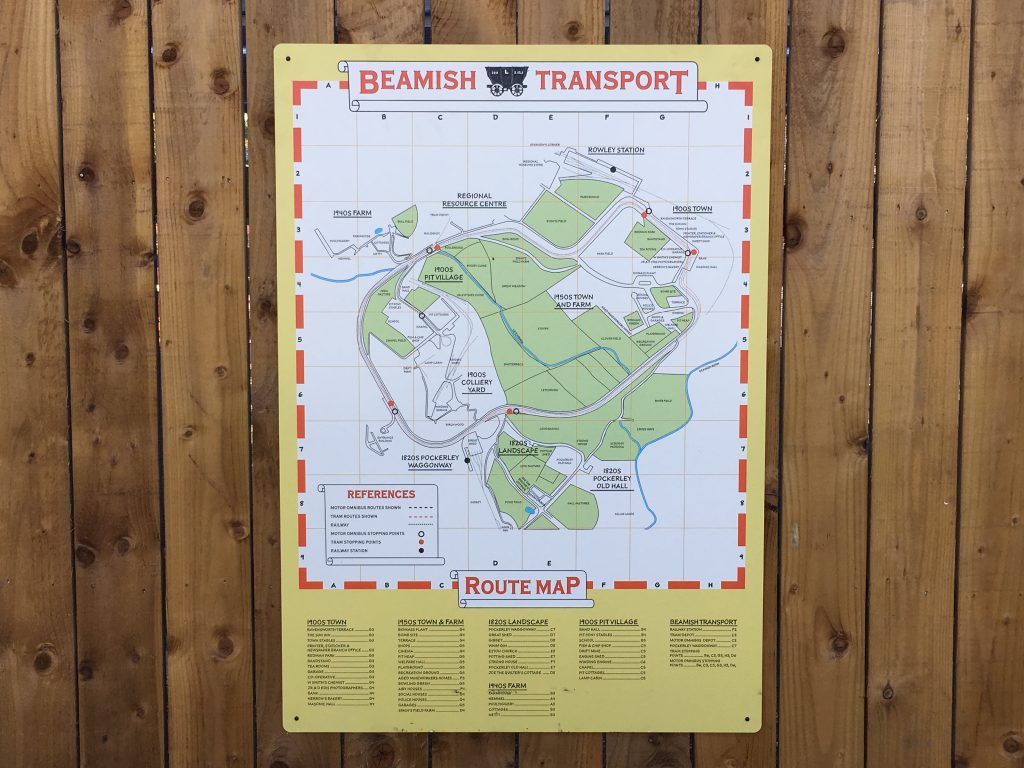

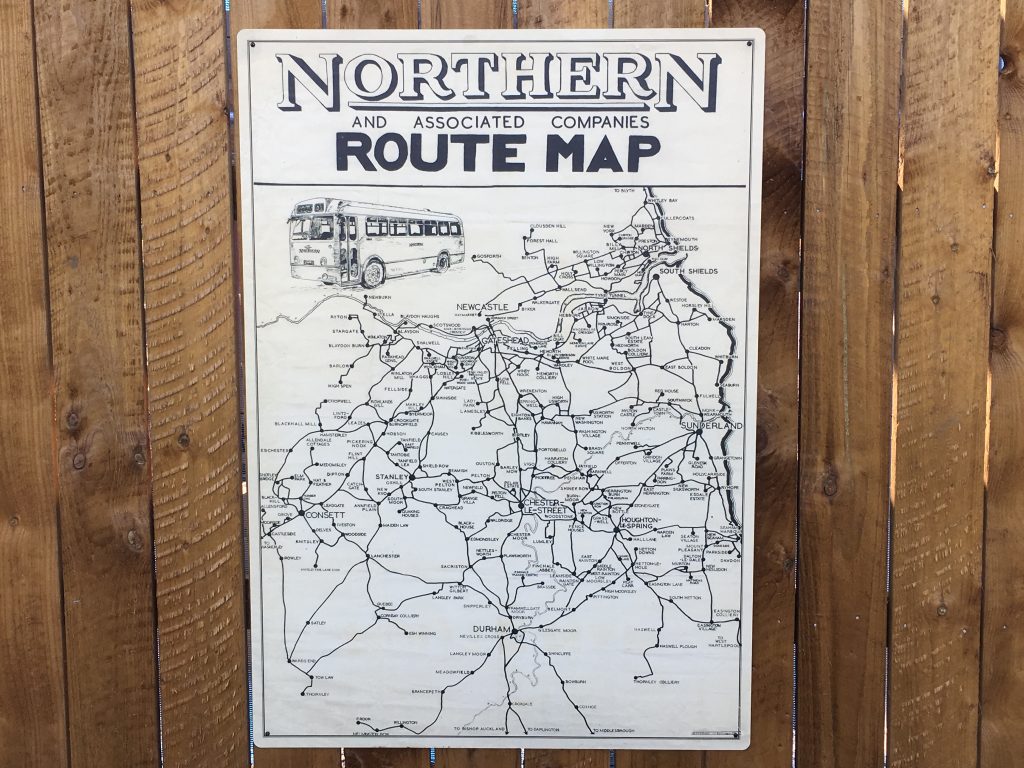

Below: The engagement team has produces some signage for the fence around the depot construction site, including a transport system map. This usefully includes the railways as well as tramway, and we will retain these signs upon completion of the depot (and live with a couple of small errors the designers seem to have incorporated!). The reproduction Northern signs and maps are part of the branding of the depot, which will represent the Northern bus company in the 40s/50s period.

An excellent T&I News bulletin!(No.12, 2019). Must visit Beamish again. Try to get there about once a month. Train Dunbar to Newcastle (1hr) ‘bus Newcastle to Beamish – ditto! Will details of when “Glyder” is working on the ng system be posted? I’m anticipating it’ll be weekends. Thanks again for T&I News. Appreciated.