T&I News 18 2022…

This first part of this week’s post focusses on the road transport – buses and trams, plus road signs! The focus of the engineering work has been on Gateshead 10 lately, but the rest of the fleet is either under repair or working hard in what has been an incredibly busy museum this month. We have also inspected two historic vehicles that are likely to join the collection later this year, and moved forward on the background research for two further railed transport projects for the future. More on these in due course, but the department and collection is certainly continuing to be a vibrant and interesting one – and one where there will be an increased emphasis on north east subjects as far as is practicable.

We are also looking forward to the Transport Gala on the 10/11 September, and beyond that are already planning the Steam Gala for April 2023! In fact, I think we have ideas all the way to 2025 now! The museum will also be contributing to events in 2025 to celebrate the 200th anniversary of the Stockton & Darlington Railway with some early discussions having taken place as to how we can support this. Meanwhile, in the workshops and out on site, the team are busy with various projects and ongoing maintenance of the hard-working fleet -particularly as the summer has been so busy (which is great!) and the vehicles (in particular the buses) so well used.

Buses

Below: Darlington 4 has been the recipient of ongoing improvements, against a list of work devised last winter. This includes new window rubbers, new side rails beneath the lower deck floor, some improvements to inspection hatches and some cosmetic work too. It is seen here basking in the sunshine last week whilst laying over between duties. When we first purchased Rotherham 220, and then Darlington 4, we had no idea how important the bus operation would become (particularly during a pandemic and then two very busy summers) and the timely construction of the bus depot and workshop certainly enabled this high level of operation within the museum to be sustained as it has been.

Below: The Dodge bus has also received some attention from the Friends volunteers, who are reconstructing the weak rear end of the body. Ash was obtained ready machined, and this is being let into the body to restore the strength in this area. This is not a ‘nut & bolt’ restoration as we very much want to conserve the originality of the bus, but ensure that it is safe and reliable to operate on high days and holidays.

Below: Our painter, Rebecca, has been working on a variety of buses and trams as they become available, refreshing handrails and floor finishes. She is also working on the batch of cast iron road signs that will form part of a project to properly and thoroughly signpost our roadways on site – with speed limits into and out of areas – removing any ambiguity or options for ‘interpretation’!

Tramcars

Below: Work on Gateshead 10’s body repairs and repaint continues on a number of days each week. Panels are rubbed back, joints repaired, beading re-secured and then any cracks filled before a coat of primer is applied. Further filling and rubbing back can then follow this, with the tram slowly turning grey as work proceeds. Contractors have been contacted regarding fitting safety glass in forward facing windows, and laminating the side windows, and the new doors have been retrieved for storage to enable them to be prepared for fitting, glazing and varnishing.

The original advertising panels have been recovered from storage but the side panels are likely to be replaced. 10 will run sans adverts, so we are looking at the colour applied to the panels – photos of 10 in service show the panels a dark shade, said to be very dark blue or black. The only known adverts carried were painted onto the roker panels (the lower side panels), rather than on the advertising boards. We will experiment with dark blue first, but if this looks strange, will revert to black for these.

Below: An example of one of the repairs – this being a sill for one of the windscreens. The rot will be dug out and a new piece of ash inserted, before filling, sanding and priming.

Below: Meanwhile, Zoe and Don are working on the track brakes, with the new guides (seen bolted in place here) being fitted, by which I mean a lot of work has to go into making them fit. These have to be square in two planes and also parallel and inline with each other. Easier said than done!

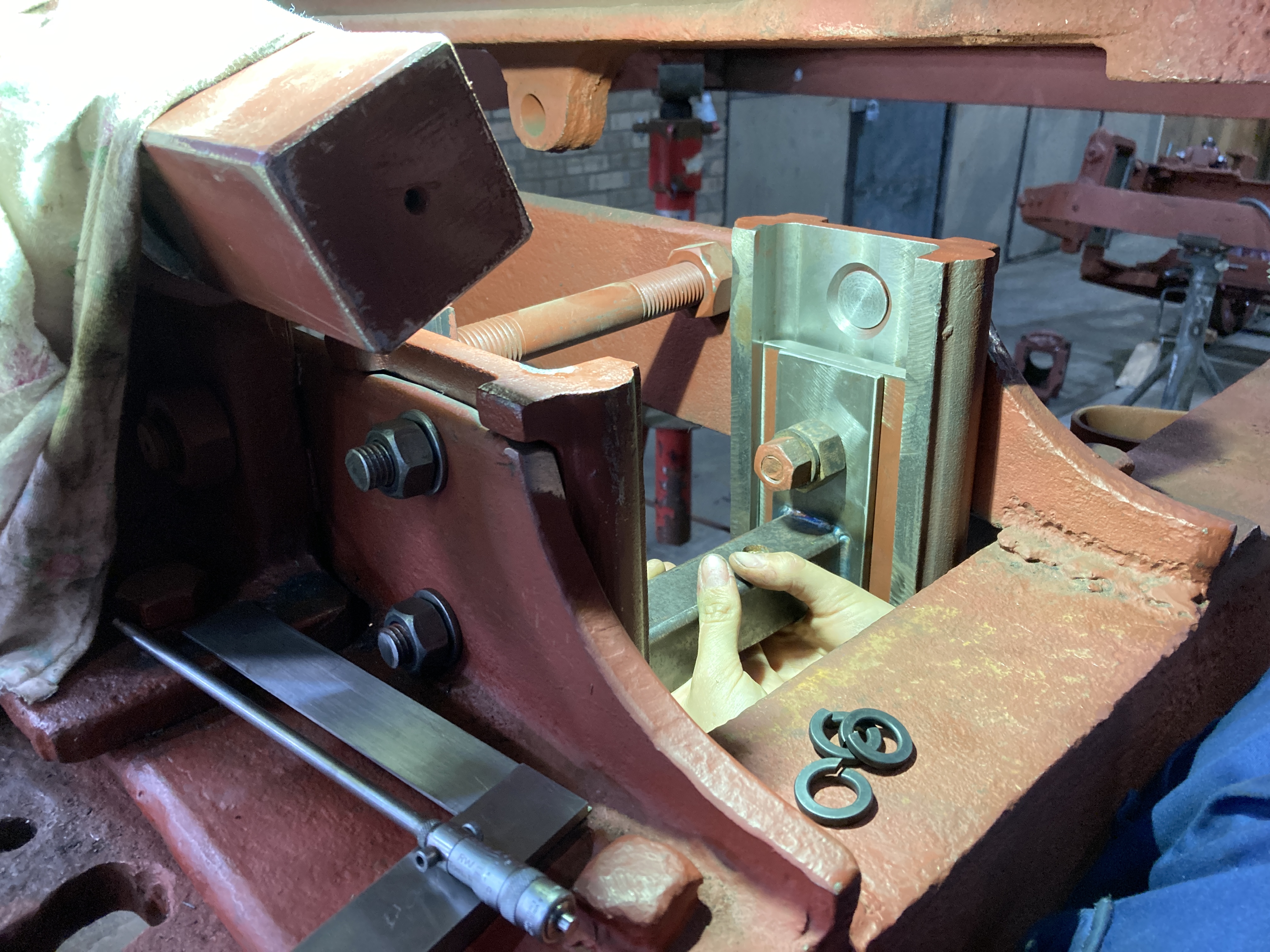

Below: To assist with fitting the guides, a jig has been manufactured so that a consistent fit can be established – the jig being seen held in place here.

Below: The current bogie frame being worked on has been elevated to a more comfortable height – using the newly commissioned gantry hoists. This makes lifts faster, safer and more controlled, useful as they bogies are lifted up and down and on and off the wheelsets at regular intervals as the parts are worked on and fitted.

Below: The usefulness of the new gantry hoist can be appreciated in this view. The wire, just visible in the top left of the photograph (with the white label – this being the reverse of a ‘Danger overhead lines’ sign) is part of the means of limiting the travel of the gantries beyond the safe working area within which they are located.

Below: Repairs to 196’s damaged (destroyed!) life tray have been completed and this was delivered back to the depot from the workshop to enable it to be fitted at the first convenient juncture. It is seen here leaning against Blackpool 31, whose resistance grids are being renewed, work that has fortunately proved to be much less expensive than we had feared. It is being carried out by the company who can trace their roots to EMB, who originally manufactured 31’s resistance box.

Strategic Planning

Readers might wonder, from time to time, how we select the projects that we do, to work on or repair, and how we prioritise the maintenance work on some vehicles ahead of others. A recent issue of the Beamish Magazine carried an article on the grading of the transport collection in this regard, and how the categories work to prioritise, say, the daily use vehicles (Category A) vs those that are used more sparingly and for more curatorially-focussed motivations. I have included this at the bottom of this post for those who might be interested in how we make these judgements.

On the transport front, our strategic plan for the team is considering what its priorities are, and also the risks. Risks include having insufficient vehicles available for service as well as a plan for skills capture and ensuring that we have a robust staff plan for operational need and succession planning. Therefore the team is seeing changes to both the shape and structure of the people-side(including some recruitment), but also enhancements to the facilities (the gantry cranes being a recent example of investment in this direction).

We are reviewing the form of operation, to see if we can create more variety in a ‘typical’ week, to create curatorial interest but also manage wear and tear on running exhibits. Vehicle planning forms a key element of this, and it has become very apparent that the tramway fleet ideally needs an additional tramcar to give some breathing space and that we should also prioritise the creation of the next Wheelchair Accessible Vehicle (a 1939 Leyland Cub bus is already owned, for this purpose). With Oporto tram196 and Sheffield tram 264 due overhauls in the not too distant future, the need to plan the use of our resources (people, time and money) is all the more important and the engineering team, once Gateshead 10’s mechanical overhaul is complete, will move on to Steam Elephant and then, probably, Oporto 196’s truck (the body will receive some cosmetic work and the framing will also be investigated). Away from site, work on Dunrobin will shortly recommence, and so we can start to plan for Rowley Station to resume operations in 2024.

No.18’s overhaul, in two phases (alluded to elsewhere on this blog) will return regular steam to the Colliery standard gauge lines, something I am very keen to ensure is a key component of our working offer, and Puffing Billy’s recent mechanical upgrades and forthcoming re-tube will also ensure the Waggonway’s operation too. A lot of this is a version of a long-standing plan, re-written to take account of the disruption caused by the pandemic, and also some changes in terms of our overall operating methodology at Beamish – looking to enhance and restore the core value of engagement, against a sustainable means of operating the exhibits.

Trolleybuses form a part of the plan too, and will operate alongside the motorbuses on the 1950s bus route, the first sections of which we should see in late 2023 (motor bus operated). The infrastructure for the trolleybus route should start to appear next year, but at this stage I cannot commit to when this might be operational – this depends on resources and external assistance to realise.

Within our sector we are quite unique in operating the variety of historic machines that we do, and at the intensity of use that the operation requires. The team supporting this is quite small, and so we must plan carefully what we do and how we do it (i.e. mix in-house and external contract work to achieve the best results and operational performance). This is an exciting challenge and so, as we formulate our plans going forward, I thought that this quick update might help put some of the news reported on this blog, into context with the ‘plan’! We have also recruited to new management positions in support of this, and I’ll describe a bit more of the personnel side in a future post.

Regarding the operating policy, here is the currently in-force version:

Operating the Transport and Industry exhibits at Beamish

A short overview on our policy and rationale

By Paul Jarman, Assistant Director – Design, Transport and Industry, and Matthew Ellis, Keeper of Transport

The operation of transport and industry artefacts at Beamish is a core principle and one which resonates with general visitors and enthusiasts for this subject matter alike. There is a general presumption that, within an open-air museum setting, collections should be seen in context, be made operational where possible/practicable and that visitors should be able to explore and interact with them in the manner that they would have done when our artefacts and objects were made and in original use.

Nationally, there have been many attempts to describe the use and conservation of working collections in museums, but none have quite fitted our requirements at Beamish, therefore we designed and evolved our own system. The aim was to create a simple and therefore effective system, usable by both collections and maintenance staff within the organisation and able to describe our attitude to the care and maintenance of working collections (and rationalise why there were some artefacts that would not be operated).

In order to categorise the usage of transport and industry artefacts (largely vehicles but also to include other items, such as stationary working exhibits and period-plant like the bakery dough mixer), the system has been devised to enable the restoration, management and maintenance to be focused so as to ensure safety in operation, ensure that performance/engagement is of the highest standard, maximise available resources and enable planning of restoration/overhauls and the precious funding that is available for these.

It is worth clarifying at this stage that this approach is specific to operations at Beamish Museum, though this document has been circulated amongst colleagues in the museum sector as a means of informing their own operational policies and guidelines.

This system was always intended as a point of guidance, and something to promote further discussion – it is not a hard and fast rule and there will always be examples that fall outside of the categories defined here.

The System

The system for categorising working, or potentially working (even if to say that there is no current potential) artefacts defines a number of states of usage and standards of condition against this. These are allocated alphabetical categories, in order to differentiate them from one another. Thus we start with A+ and move down the scale to E, as follows:

| Category | Category Description | Examples |

| A+ | An artefact required for daily operation, requires a high degree of reliability and which forms part of a core operation for which there is no readily available “spare” or temporary replacement | Bakery dough mixer |

| A | An artefact which is usually required for daily operation, requires a high degree of reliability and which forms part of a core operation but where there may be a “spare” or alternative artefact to operate | Tramcars, buses, WAVs, Dunrobin, Waggonway locomotives, Town cars, Morris Commercial, steam winding engine |

| B | An artefact which might be considered for regular operation and therefore requires a good degree of availability but is not necessarily part of a core operation | No. 1 Coffee Pot, No. 18 Lewin, Samson, printing presses, Crewe Tractor, Leyland Cub lorry, Model T Tourer and Model T Ton-truck |

| C | An artefact suitable for occasional operation with certain restrictions of usage/range of operation and which is not part of a core operation but used to enhance performance in some areas on occasion | Barford & Perkins D4 motor roller, Matchless combination, Dene motorcycles, garage oil engine, Ford Model T Tourer, SOS and Dodge buses |

| D | An artefact that is largely static (and non-operational) but which can be moved, with specialised management, should there be a requirement to do so | AW (Armstrong Whitworth?) car, Renault car, SHEW car, Quarry Hunslet Edward Sholto |

| E | An artefact that would usually be considered entirely static, either due to its fragile state or because of some technical consideration and would only be moved as part of a special project | Stephenson engine, Warden Law engine, NER snowplough, Roker, NER Riding van and Birdcage Brakevan |

The definition of working collections are summarised in the table below. The description is not exhaustive, but serves to guide and direct the reader/user of this system.

| Green | Working Collection | Regular operation (daily or weekly) using Engagement Team staff |

| Amber | Special Working Collection | Occasional operation (monthly or less) using skilled engineering and/or curatorial team members |

| Red | Display Collection | Movements to be carried out only when necessary and only by skilled engineering or appropriately competent curatorial team members |

Whilst the table serves to explain the basic principle of our system, further explanation is necessary, and serves to show how it is applied here at Beamish.

Category A/A+: Within the working collections there are clearly artefacts that have a high degree of operational availability required – such as the trams, or Wheelchair Accessible Vehicles. The A category has therefore been supplemented with an A+ to reflect this. The wider A category would include the tramcars, but as multiple vehicles are available, the individual requirements are not quite so vital. Therefore, in restoration terms and maintenance planning, an A+ artefact would be subject to more rigour in order to deliver the higher degree of reliability and therefore availability of operation required for these core operations. Until there were two Wheelchair Accessible Vehicles, the first bus, J2007, was also categorised as an A+ artefact within the working collection.

Category B: This category includes artefacts which are still regularly operated but are not at the core of daily operation. They are also artefacts that may be A/A+ artefacts which, due to wear or age, are reduced in status but remain available for operation – this has been reflected in the usage of some tramcars for instance. A review of the condition and potential usage would be carried out and costed in order to restore the artefact to a higher status. A current example of this would be the printing presses in the print shop – where availability of competent operatives is as much a factor in the potential usage as the condition of the press. The Model T Crewe Tractor is another example, likewise the Morris Commercial or Leyland Cub tipper.

Category C: These artefacts are operational and potentially quite fragile or require operation by someone with a specific competence. Thus the motorcycles fit this category very well as they are in full working order and available for use, but are managed according to available riders and also in deference to their age/originality.

Category D: In this category the artefact is potentially operable (i.e. is complete and intact) but is not so at present and therefore is either performing a static display function or in storage. A survey of condition and potential usage would enable movement upwards through the scale and an example of this is the Dodge bus, now undergoing restoration by the Friends of Beamish.

Category E: The artefacts in this category would usually be of a fragile state, of great value or originality, or derelict. The Seaham Harbour coal drops and the Stephenson works engine are examples here (and are also long-term loans in with conditions attached). Additional examples would include the Warden Law engine or the North Eastern Railway snowplough, currently stored in the Regional Museum Store.

Nearly all of the artefacts in the collections at Beamish have the potential to move up and down the categories and whilst downward movement will generally come with age/use and therefore increased management in terms of monitoring wear and tear/condition, the upward movement requires more in depth consideration of the potential performance/use at Beamish, the work required and its impact upon the object itself (i.e. degree of originality) and also the cost. It is also important to note that there is no variance in levels of safety, or applied standards, between categories where artefacts are operational.

Hopefully readers have found this description useful. It underpins much of the narrative on transport maintenance that appears in these pages and also reinforces our consideration of the management of museum collections, particularly those that move! We have evolved this system over a number of years and it is an approach (and therefore a document) that continues to change and develop, and it will certainly continue to do so as the needs of the museum and its operations change, evolve or are reviewed.

Photos in this blog post by Don Cook and Paul Jarman

Any update on the 2 locos stored in black shed at pit village ie the second coffee pot and Newcastle for example have they been looked at to see what work is needed. Newcastle is in scrap yard condition and the parts fall into 3 areas 1 parts that need restoring to as new 2 parts that are beyond reuse and need replaced and 3 parts that are missing all together.

i know this will cost money but it won’t cost a lot to check to see what is needed.

regards Gary

Hi Gary. No update on these, they remain in store (Newcastle, No.17 and Ashover). We have assessed all three, with Ashover a slow-burn project by members of the Ffestiniog Railway Society for eventual use, as a loan, on the narrow gauge at Beamish (it is a diesel locomotive – see posts). Newcastle has been inspected and has also had an initial boiler assessment, whilst No.17 needs a new boiler as well as comprehensive mechanical overhaul and restoration of the frame plates to their original length. I would say that Newcastle is rather better than scrapyard condition, and it received quite a lot of attention from its previous owner who was able to steam it on a private railway in the 1980s. It is complete. All of the reports that we carry out are filed in each engine’s records for future reference should they move into an overhaul and restoraiton programme (no plans for them to do so at present).

Cheers

Paul

Is that “Locomotion” I spy behind the gantry hoists supporting tramcar work!

Hi Michael – it’s Steam Elephant, which will be the next engineering project one Gateshead 10’s bogies are complete. It will have a boiler lift in order to expose the valve gear, which is very tired and in need of overhaul. Cheers, Paul

Thanks, Paul. I’ve heard “Locomotion” is at Locomomotive Services, Loughborough. I did witness it briefly in ‘Head of Steam’, North Road Station, Darlington following it’s (very) short placement there as a compromise to the 1825 engine going to Shildon. Darlington is now “Locomotion-less”!

Hi Paul Thanks for update on stored locos waiting their “place” for overhaul.

regards Gary