T&I News 2 2024…

I think it is fair to say that the blog is becoming more of a monthly newsletter now – and certainly for the T&I posts, I think this is a reasonable aspiration in terms of content and the time to write it. Additional posts will appear, as ever, to reflect particular themes or news stories – and shortly I’ll be uploading information about the forthcoming Wheels of Industry event in April (this being the new name for the refreshed transport event that we hold in the spring). We are also planning for June’s Fares Please! event too. We won’t be having any other transport events this year, so do make the most of these if you can make it.

On the steam side, a the annual boiler exams and testing have been completed. The Steam Mule will not be kept in working order, as it sees so little use and with a looming need for stripping for its ten-yearly, it isn’t really worth keeping on the books as a working engine. It will be cleaned and kept on display however. The Waggonway operated through half-term and we should see the home-fleet all readied for Easter onwards, to make them available for operation this year.

On the buses

Below: B1349 has been a fairly permanent resident in the workshop in recent months. The bus has had all of its braking system overhauled (with cylinders bored and sleeved, for example). Whilst that work was undertaken by a contractor, the opportunity to carry out other work was also taken, including repairs to parts of the chassis, renewal of much of the staircase, some body frame repairs and a general smartening up of its appearance too, including the top deck handrails. This is a hard-working bus and as one of only two that can operate the Colliery service, it is an essential vehicle within the fleet.

Below: The curse of WordPress strikes again and I just cannot get these images to orientate correctly – they are the right way around when I download them, honest! If you tilt your head, you can see the overhauled staircases for B1349. New treads and risers have been made, along with the framework that supports them. The whole lot has been shot-blasted and powder-coated where appropriate, and the Saxe Blue has been restored to the side panels. New grip strips have been fitted too. The work has put years back into the life of the platform and stairs area – but it is probably that few will notice that it is different!

Below: Rotherham 220’s cosmetic overhaul is now complete (the new transfers being fitted a week ago). Some outstanding mechanical work remains, plus repairs to the exhaust. It will then be inspected and put back into service. It looks stunning in its new coat of paint and has been much-missed in service.

The work on B1219 and Rotherham 220 has been part of a programme of thorough inspection and snagging, to sort out those things that aren’t a safety issue, but are desirable in terms of the longevity of the vehicles. Whilst 220 has been out of service, we’ve been enjoying the regular sight of Sunderland 13 around the museum (it’s been with us a while now and fits in very well!). We are taking steps to further strengthen the bus fleet, which is working at an increasingly intensive rate, but also want to get back to some of the curatorial work, not least commissioning the Leyland Lion for demonstration use (initially). The Friends of Beamish team are also making good progress on the mechanical restoration of the Dodge bus, so this area of the museum’s working collection is looking very healthy at the moment.

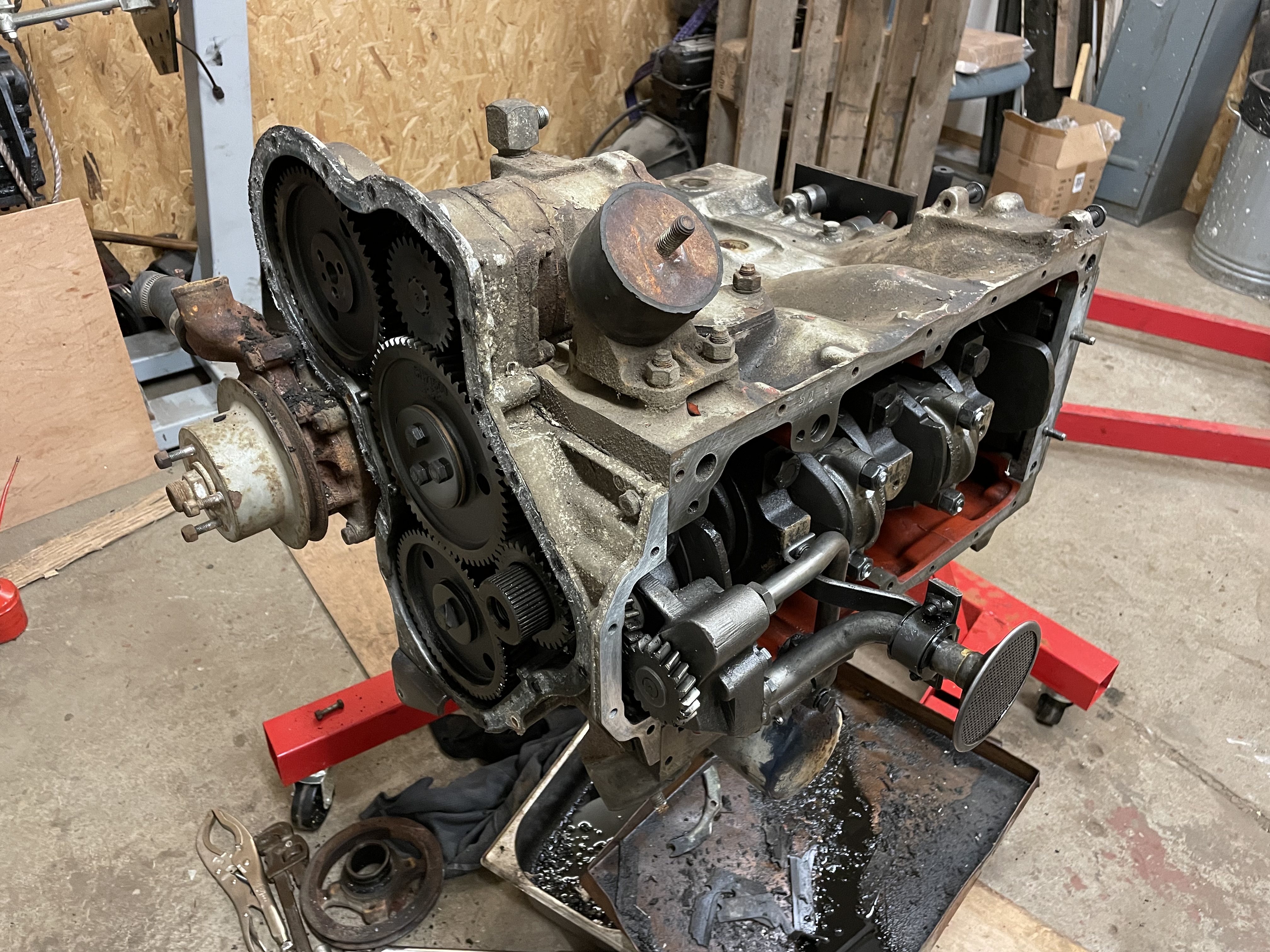

Below: The engine overhaul for West Riding 560 progresses slowly. The new pistons have been fitted, so attention has turned to various ancillary attachments for the engine (which will also include the starter motor). Fortunately an overhaul kit for the engine has been sourced, which is greatly assisting progress. The new mounting brackets have been made, so once the engine overhaul is complete, it will be trial fitted into the chassis. The gearbox is dismantled, with new synchronising rings needed – for which we’ve turned to a specialist manufacturer in the Midlands. Once these are available, the gearbox will be sent to one of our local suppliers for overhaul and assembly. This is needed before the next stage of work is carried out, which will be manufacture of a new propshaft. It’s easy to see, when broken down like this, how it takes so long to overhaul/restore vehicles!

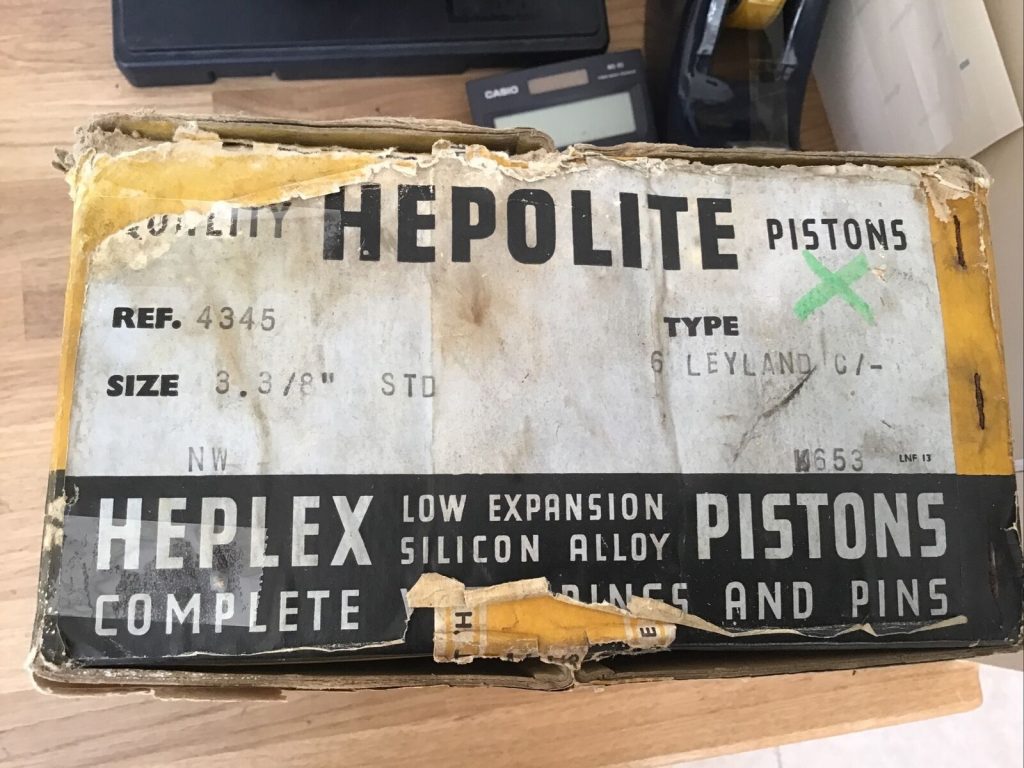

Below: A handy eBay find recently was this box of pistons, to suit the Leyland six-cylinder engine used in 716, the tipper and some of the spare engines that we hold in stock. I have several eBay searches running at all times, so it is always good when they yield items such as these from time to time.

Below: Luke Griffiths took this photo of Crosville 716 in an unusual location, whilst it was engaged on staff training duties. It is seen at Rowley Station, complete with a suitable veneer of grime! This is washed off on a daily basis so reflects the filthy conditions that we’ve recently had (weather and road dust) on site.

Dunrobin

The Severn Valley Railway has sub-contracted the construction of the new cab/bunker for Dunrobin to the Ffestiniog & Welsh Highland Railway. The F&WHR made the new tanks several years ago, so have now manufactured most of the new superstructure for Dunrobin. Matt Ellis sent these photos of the work underway at the railway’s Boston Lodge works. The original cab was surveyed, then drawn up as a CAD package, enabling the components to be delivered pre-cut to size and shape, for assembly at Boston Lodge. This is a very effective way of manufacturing superstructures and large assemblies such as this.

Below: The original cab is being dismantled, ro release handrails, beading and other items that are being recovered for the replacement superstructure.

Below: The curse of the sideways photos again I’m afraid… This view shows the flat-pack pallet of parts, with the cab back most prominent in this view.

Below: The new superstructure taking shape on the welding table at Boston Lodge. This is the view from the rear of the bunker, looking through towards the cab. The hole is the aperture for shovelling coal through. To the left and right are water compartments – which were a feature that gave a marginally extended range for the locomotive.

Below: Sideways again I’m afraid! Here is one of the profile-cut cab/bunker sides, resting against the original superstructure. Note the angle tacked in place, retrieved from the old bunker.

Below: With the cab back tacked in place, the shape of the structure becomes clear. This view shows the bench seat, upon which the Duke’s guests would reside for their journeys to the castle from Inverness.

Photos in this post by Paul Jarman/Matt Ellis/Luke Griffiths

Hello Paul & co

Many thanks for your latest update it is much appreciated.

Of particular interest to me is your reports about the progress of DUNROBIN because I had the privilege of driving this loco in the early 1960’s whilst working at the Romney Hythe & Dymchurch Railway.

She was then owned by Captain Howey and was kept in the DUNROBIN shed together with the Royal Carriage and whilst there a number of us used to run her along an approx 200M private siding into the RH&DR,from the main line station at Littlestone on Sea.

Prior to getting her into steam I was then agile enough,at that time, to get into her firebox and clean out and prepare for the visit of the boiler inspector!!

I am looking forward very much to coming to your excellent museum when DUNROBIN returns and hopefully watch her running again in the UK!!

Best wishes to you all

David

Might an ex London RTL painted in OK Motor Services livery be a possibility’s? I understand that there are quite a few in preservation and one has recently been put into Barton livery. OK had ten of them and they ran through the 1960’s, I remember them fondly. It would be a good way to expand the bus fleet.

Hi John

Good suggestion! We currently have a bus in mind to add to the fleet, and this is progressing towards a conclusion at the moment, but I’ll keep your suggestion in mind.

Best wishes

Paul