T&I News 9 2023…

This post covers quite a few aspects of the transport activity at the museum, as I haven’t posted for a little while and there is quite a lot to catch up on. A lot of work is also underway behind the scenes on the administrative elements of operating the transport and industry functions, staff competence and such matters as SMS and insurance. These probably occupy 4/5 of our time, if that helps give a sense of just how important these elements are.

The impact of temporarily closing the machine shop whilst we make facility improvements is being felt, but the finished work will put us in a much better position for the future, including three additional machines, which will increase the breadth of the work that can be carried out in-house.

Sheffield 264 is out of service whilst a motor fault is investigated (not the same motor as failed last year). We hope that we will have this diagnosed and repaired as soon as possible.

Bus conductor training

Below: This year’s new cohort of tramway/bus staff have been undergoing training. This includes familiarisation with the WAV access lifts, and the procedure for egress should the lift fail in service – the process for which is shown here.

Road Steam/Transport Ops

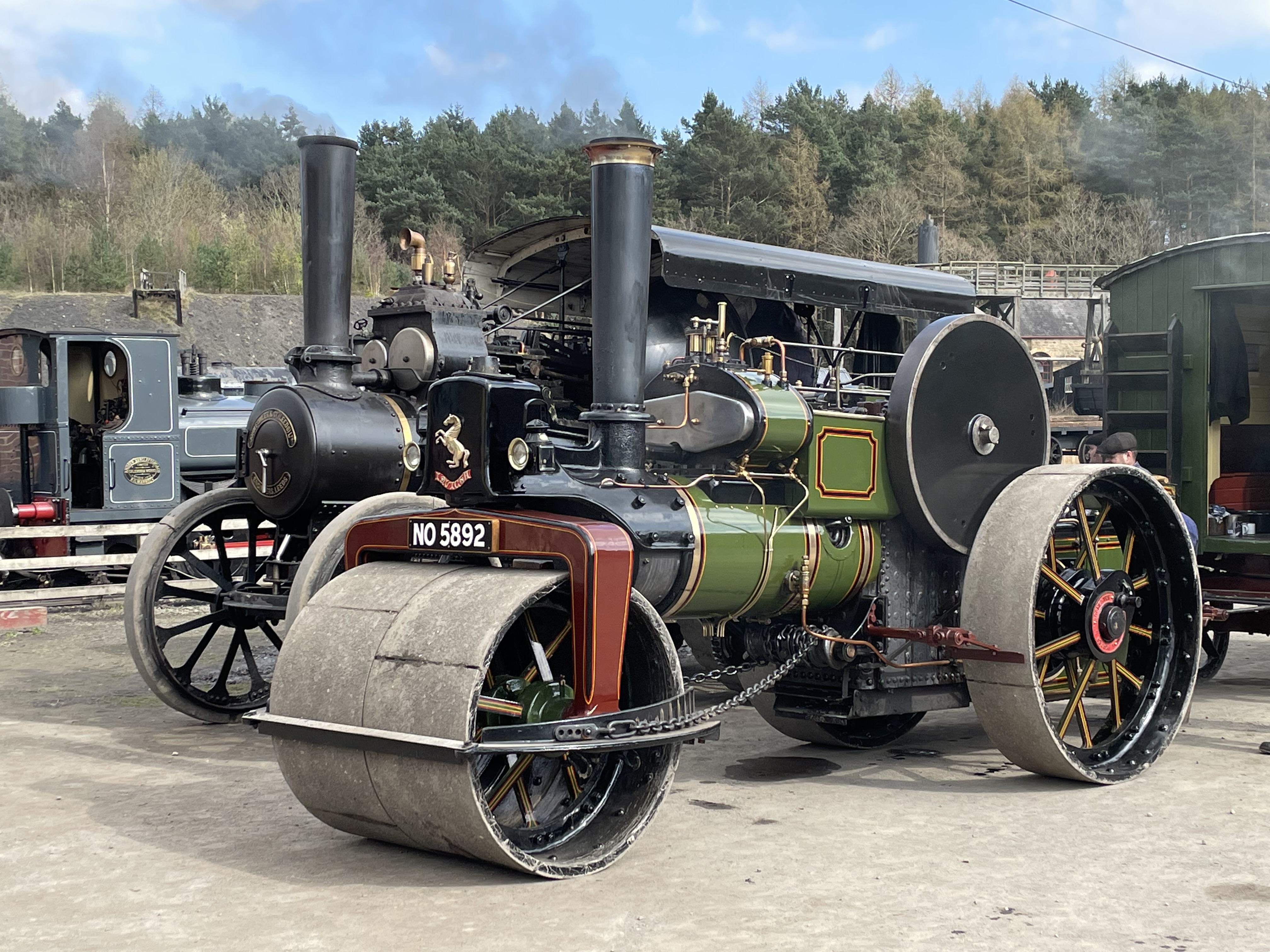

Below: We are hosting a number of steam rollers, which have remained on site following the steam gala. These are out and about most weekends (excluding the Fares Please! event on the 6-8 May).

Below: The Council Depot displays have been re-shuffled in order to accommodate visiting engines – the little Barford & Perkins A-type now being in the workshop lean-to. There is a great project around this roller at some point in the future – one for the ‘to do’ list!

Rowley Station

Below: The repairs to the chimney and repainting of the ventilator having been completed, the scaffolding has been removed from Rowley Station. We are now developing a programme of work that will see the station operations re-activated next year at some point, meanwhile the gardens are tended and the fires burning.

Below: The PW team are working on the curved section of the running line behind the Town at present, to create a consistent (and less dramatic) cant in this area. This will address one of the infrastructure items on the list – but it is a long list and there is much to do before we introduce Dunrobin to the scene…

Below: This view illustrates the newly packed section in the foreground, and contrasts it with the section yet to be tackled in the middle distance. Considerably less cant is required for this section than has been applied previously, and evidence of the raising of the low-rail (the inside one if you prefer) can be seen from all of the pockets of ballast where the tamping machines have been forcing ballast beneath the sleepers (sections of rail being jacked upwards to enable this work to take place). Some sleepers are also earmarked for replacement during this phase of work and new ballast is also being introduced to improve the shoulder at the edge of the sleepers.

Outdoor Works

Below: We’ve had more support from Nexus, with more of their teams spending time at Beamish. Work has included repainting (in bitumen) traction pole bases, and then restoring the cement caps that protect the poles from surface water. They have also assisted with preparing new span wires for installation in a number of locations.

Below: Opposite the railway’s easterly end, the new cinema structure is rapidly taking shape – the outline and position of the entrance and upper circle being very clear while it stands in this skeletal form. Since this photo was taken, the steelwork has been completed and the adjacent parade of shops also erected.

Below: For the interest of those wondering what is going on in the field alongside the Tramway between Pockerley and the Town, work on the water attenuation pond continues, as the hole becomes deeper and wider! The outfall for this pond is now being developed, with a digger mooching around the woods putting this in place. The level of water in the pond will rise and fall as it acts as a regulator for surface water coming from the 1950s urban area. The work itself has become quite a popular spectacle in itself, in particular for younger visitors!

Below: Improvements to the road network on site continue, with the bus turning area at Foulbridge being made rather more permanent than the muddy surface that previously existed. The area between the tram rails will also be lifted to restore the surface level and prevent bus tyres scrubbing on the check-rails in this area.

NER 559

Below: The boiler of the K Class has now been completed, tested and painted. It was delivered to Beamish on Wednesday and placed onto a flat waggon where it will reside until required for the appropriate step in the project. The design work for the crank axle is complete and this will be ordered shortly, with the cylinder block being the next large chunk to that will follow this.

Rolling Stock and Engineering

Below: The Waggonway coach has returned from Darlington, where it had been surveyed as part of the work to plan its replacement. It will be stored in the Colliery for now, before being stripped for spares and converted to a flat waggon (sans the air brakes).

Below: No.18’s boiler has been returned to its frames and the locomotive moved back to the Colliery for storage, pending any progress on its overhaul, plans for which will be prepared later in the year.

Below: In pursuit of having better records of vehicle mileages (currently established via the daily log books), the core running fleet of buses are being fitted with odometers (hub-mounted) -as seen fitted to Darlington 4. Though not the prettiest of additions, it is extremely useful to have this information.

Below: Puffing Billy’s tender chassis overhaul is nearing completion with the two new pedestals fitted and the wheelsets reversed (so that the one with more substantial journals is beneath the water tank). This will shortly return to the Waggonway for the tank to be placed back on top.

Below: David Young has been continuing the machining work on 721’s axleboxes, with three of these test fitted. This view shows the front axle and axleboxes in situ.

All interesting progress as always. Will there be any news on the ‘Fares Please!’ event soon by the way, as it is rapidly approaching? News of any plans to celebrate the tramway’s 50th anniversary, which is briefly mentioned on the Beamish website in the description for this event, would be especially welcome. Presumably Gateshead 10 won’t be ready in time, will there perhaps be some sort of celebration when it is completed?

Hi Andrew. Unfortunately I’ve run into some issues with the blog and these will take a few days to resolve. The post that I was putting up regarding the Fares Please! event has therefore not appeared. Here is the text from it which I hope will go some way to answering your query. Best wishes, Paul

Next weekend we will be holding a new, and possibly one-off transport event, titled ‘Fares Please!’

This was originally going to focus on the Tramway’s fiftieth anniversary (May 1973 – May 2023) but has been expanded to include all passenger (buses and trams) transport at the museum.

I originally had great plans for celebrating the Tramway’s birthday, but unfortunately it won’t be quite the party that was planned! Gateshead 10’s overhaul was targetted at completion for this event, but with a number of challenges facing the engineering team, including the temporary closure of the machine shop to allow us to upgrade this vital facility, several staff leaving for other roles elsewhere and some breakdowns that required urgent action, 10’s overhaul will not be completed until spring 2024 at the earliest. This is disappointing, but we remain committed to maintaining the full scope of work for this project.

We were also hoping to have a visiting tramcar for the anniversary celebrations, but in the end we were not able to pursue this either. Sheffield 264’s recent motor troubles struck again and so we are down to four trams for this coming weekend, though we have a good number of historic buses visiting (and in passenger service), as well as the model tramway exhibition in the Welfare Hall on Sunday and Monday.

This does lead me to wonder about holding this event annually, and then really showcase the tramway at a point in the future when we are better able to do so. It is obviously disappointing for us not to be able to deliver the event we hoped for and know that others have come to expect from us, but these are still challenging times for heritage transport operators and we face one of the greatest of these in the recruitment and retention of suitably skilled staff; without whom none of it is possible – so this must remain the focus for now. That said, we’ve invested huge amounts in the Tramway infrastructure in the last six months, and will continue with this through the next few years to make sure that it continues to be robust, reliable and safe.

Of the tramway itself, the next phase of PW work is currently being costed, which will focus on the route between Foulbridge and the Entrance (a section that sees a degree of movement in hot weather). Blackpool 31 and Newcastle 114 venture out when the weather permits (it’s been a dreary spring so far!) and Oporto 196, Sunderland 16 and Sheffield 264 have therefore seen the majority of use so far this year. 264’s motor cooling fan failure prompted the removal of the motor and we are considering whether to go ahead and have the motor overhauled at the same time as the fan is repaired.

This means a large proportion of the next mechanical overhaul of 264 has been carried out so we may withdraw it when 10 returns, to carry out the truck overhaul too. The tram is tired, but it offers the best route towards restoring fleet capacity, when compared to Oporto 196, which needs work on the truck and the body condition thoroughly exploring. Both options are allowed for in the strategic plan, and ideally both would be completed within the timescale of that plan – but we shall have to see how we get on with recruitment over the next few months to fill the vacancies that have recently emerged.