Transport & Engineering Diary July 2025 Part 2

We round off July’s diary updates with more progress on Gateshead 10 and an exciting development on the Daimler CC lorry. Gateshead 10 has received attention to its glazing, to complete a process of fitting safety glass on all forward facing windows (including the internal saloon partition) and appointing a contractor to install bomb-blast window coatings on the side windows (this being the same material as is fitted to retail outlets in shopping centres, for example, and which is designed to prevent the glass shattering and being displaced by external/internal forces). The month also saw a project progress meeting held, to review the programme and identify any looming challenges that might interrupt or slow the rate of work down.

Gateshead 10

Below: The worn handbrake components from this tram have arrived in the machine shop, been stripped and work has started on their overhaul. The wear manifests itself in ‘sloppy’ fitting components and excessive play in operation. The work entails removing this play and restoring the correct clearances for effective operation.

Below: Using one brake column as an example, here we see a witness turning around the diameter of the shaft (the shiny bit) – this is to enable it to sit in the steady on the lathe when the shaft is turned around (see next photos).

Below: The steady can be seen to the right, with the bright witness section just visible.

Below: The internal bushes in the shaft can now be bored out and prepared for replacements to be made and fitted.

Below: In short-order, the overhaul of these components has been completed and they are seen awaiting removal to the paintshop.

Below: A couple of close-ups showing the new bushes in position.

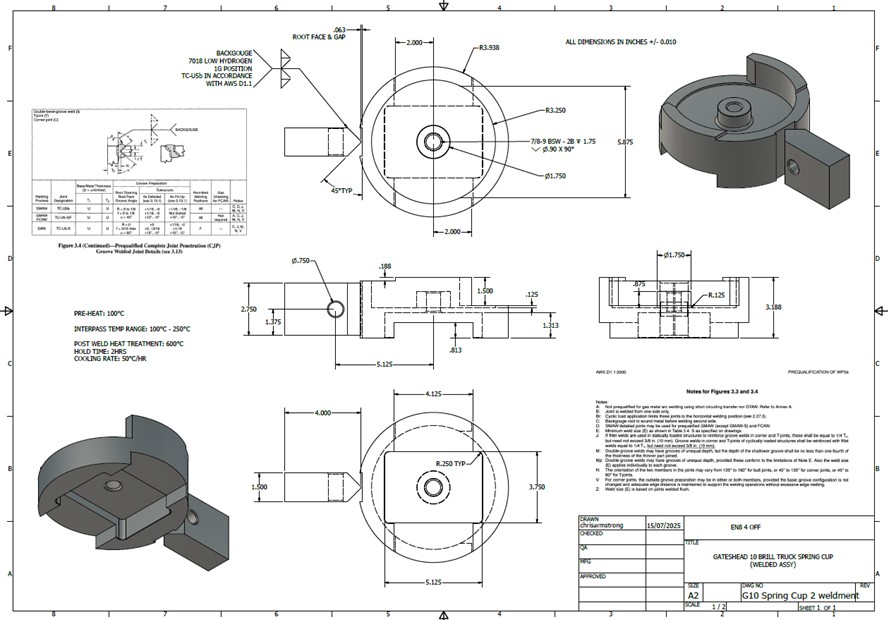

Below: In July Part 1, we saw the coil spring cups heading off for welding of the anchor point for the control arms. Here is Chris’ drawing of the components, with methodology and weld specification for the job. The spec requires post-welding heat treatment – which fortunately the electric kiln in the pottery at Pockerley is capable of achieving for us.

Such drawings and specifications are an important part of the change-control process we have to demonstrate for work of this nature – it is no longer sufficient to simply carry out the job, but it must have a design and evidence trail behind it. The drawings are appended to a log, which describes the rationale and process – this is important from an engineering point of view (and is potentially auditable by our regulators) but also the curatorial aspect too, recording a design change made to the original, and why we elected to carry it out, and how.

Below:The swaybar assembly for Gateshead 10 has been put back together. This was previously overhauled some years back by David Young, but additional lubricating points have been added and the components repainted in readiness for fitting on the underside of the tram. The swaybar communicates the brake inputs via the hand brake/air brake cylinder, to the linkages on the bogies, applying the shoe or track brakes (or both) as required.

Other news from around the workshops…

Below: Meanwhile, elsewhere in the building, Newcastle 114 has received more yellow paint as part of the work to prepare it for service again in 2026… The electrical control equipment of both 114 and Gateshead 10 is being assessed, to see if we can incorporate some modern materials that will ease maintenance in the future, something we are working with colleagues elsewhere in the heritage tramway sector on. This means that resources can be pooled to everyone’s advantage, rather than separate avenues being pursued – there is, after all, little benefit to duplicating work and effort! I will also give some thought to the advertising panels carried on 114 and I think a return to route-boards may be appropriate unless any suitable advertisers come forward wanting their name/product on these.

Below: New tyres have arrived for the Armstrong Whitworth car, as part of it’s ongoing ‘improvement’. The appropriate products to revive and smarten up the canvas roof are also on order and a plan is in hand for some work on the wooden bulkhead this winter, which is varnished and has tarnished and faded over time.

Below: The engine has been removed from the Daimler CK, which entailed removal of the front axle, lifting the lorry so that the engine could be removed from below, then reassembling the axle etc. so that the lorry remains mobile.

Below: The Daimler has a 2 – 3 ton carrying capacity and a wheelbase of 13′ 6″. A 4-speed crash gearbox is connected to the rear axle via a cone clutch and worm drive. The footbrake acts on the transmission whilst a handbrake acts on the rear wheels only. The engine is very interesting, being a Knight 4 cylinder sleeve valve petrol engine rated at 22.4hp. This was a design originating in the USA and was used by Daimler from 1908 through until 1933 (replacing more familiar poppet valve types).

It was built in 1923 by the Daimler Company Limited (Coventry), weighs 3 tons – 8 cwt – 44 lbs and was supplied to vehicle dealer J. H. Sparshatt of Portsmouth. It was sold by Sparshatts from their stand at the 1923 Olympia Exhibition (the bodywork being built by Sparshatts) to J Stride & Sons of Portsmouth who were market gardeners. In 1957 it was re-purchased by Jack Sparshatt, becoming one of the first preserved commercial transport vehicles in what was then a very embryonic heritage movement.

The Sparshatt business had started with the reconditioning and sale of ex military equipment and this 3 ton lorry was of a design not a million miles away from the subsidy lorries produced by numerous manufacturers in WW1. It is our intention to restore the lorry to its original condition and reinstate the original wings, that are in store at the museum.

Steam Elephant

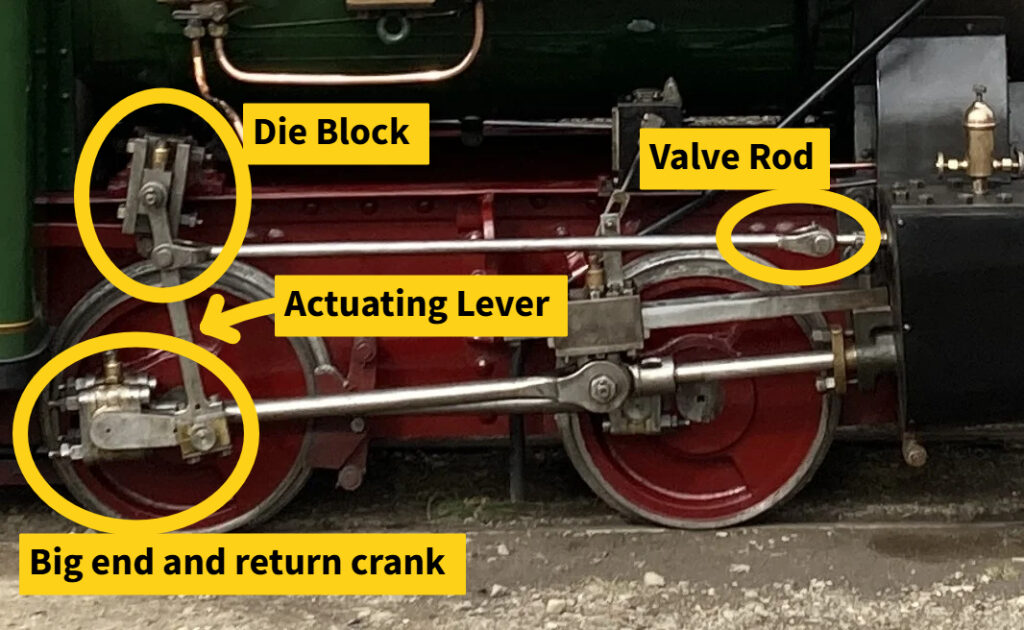

Below: Work on the overhaul and reassembly of the valve gear on Steam Elephant continues. The die block surfaces were badly worn and pitted, so these have been replaced – the new (with old below) is shown in this view.

Below: The overhauled actuating links/rods are shown here, with die block and new bushes for the valve rod connection clearly visible.

Below: The eccentric straps have been refitted to the locomotive, which is the grey/bronze item seen here, surrounding the eccentric itself, which is the black-painted circular casting attached to the axle. On top of the eccentric is the actuating rod/link/lever (choose the term you prefer!). The inside face of the timber locomotive frame is visible behind these, as is the oil reservoir for lubricating the eccentric – also revealing why Steam Elephant can only be prepared for operation over a pit. The reversing rod linkage can be seen running horizontally to the right.

Below: A close up view of the die block, looking upwards. The eye of the reversing rod is clearly visible, which engages with the die block in order to bias this towards forwards/backwards gear, with mid-gear in the middle position.

Below: Steam Elephant has a derivation of Hackworth-type valve gear. When designed as a replica, it was recognised that a driving position on the side of the locomotive was not desirable, and so the gab-levers that control the valve events would not be accessible. Locomotion No.1 has these levers and a substantial railing on the side of the locomotive in it’s current form, in order that the driver can be positioned alongside the boiler and the gab handles can be disconnected from the valve rods in order to set the locomotive in motion, with the levers then being ‘latched’ as they pass spiggots on the rods, effectively making the valve-gear self-actuated from that point onwards.

Locomotion No.1 is fitted with a slip-eccentric to enable it to reverse, and the eccentric is pulled around by the movement of the locomotive, in the direction of desired travel as the manual input by the driver in setting the gab handles (and controlling which end of the cylinder steam is admitted to first), allowing the driver to then latch the gab handles as described above. If starting on a downhill gradient, the movement of the locomotive is sufficient to provide this input, and it can be left latched-in. At the Wagonway, it was always driven from the gab handles, with the latching taking place once in motion – something of an art that took practice and some understanding of the position of the wheel cranks when setting the gabs (valve events).

To avoid this procedure, Steam Elephant has the addition of the Hackworth components, this enables a reversing lever (or Johnson Bar, to use North American parlance), which actually moves in a vertical plane, to be fitted and so provide the directional input from the footplate at the rear of the locomotive. This acts on the die block to bias the movement forward or backward. It perhaps makes sense to look at Hackworth valve gear on a Kerr Stuart Wren, in this case Peter Pan, which shows the components more clearly. The big end and return crank on the Wren is replaced by the eccentric on Steam Elephant, having the valve gear in between its frames.

Rowley Station operation for summer holiday weekends

Below: The summer holidays arrived, No.2 made the journey across from Tanfield to operate through to the end of September, and so the rains came too! Fortunately not for long, and the site as a whole has needed dampening down somewhat. Here is No.2 on the first day of the summer holiday operation on the 19th July. Again, we are grateful to the Tanfield Railway for assisting us on the motive power front once again.

Below: Despite the rain, my son was delighted to see No.2 back again, even in the pouring rain!

Below: Puddles also seem to hold a strong appeal!

Below: I rather like the open-doors view, waiting for passengers… There were quite a few riding, despite the weather (or perhaps because it offers some respite from the rain!), though not nearly as many as during Whit week – reflecting more of the ‘normal’ level of operation that can be expected.

Below: Coffee Pot also had a day out in the rain last week, to reposition the chaldron waggons so that they are located in the top yard and form part of the engagement carried out in that area.

North Western Road Car Company Bus No.346

Below: We were recently offered the remains of a Bristol L5G bus, 1938-built JA 7770, which operated with the North Western Road Car Company as their fleet No.346. The chassis and cab have been stored in the East Midlands and were delivered to Beamish in late July, to be stripped of major components (engine and gearbox) and then the chassis placed in store. As and when we get around to the restoration of United BL039, also a L5G, then having a pool of potentially usable parts available will greatly help with that project. No.346 is beyond economic restoration itself, but it will benefit another project and hopefully the ongoing operation of another Bristol vehicle.

And with this post, we move into August – where has the year so far gone?! This is a critical period for the museum, operationally, as we expect some of our largest visitor numbers – it is therefore inevitable that things break down in this period too! As I write, the Leyland Cub WAV is with a contractor for work on one of the doors (which has been replaced as part of this work), whilst the other blew a hydraulic line on the lift in solidarity. These sorts of things are where having the right people on the ground comes into its own.

Next time we should see further progress on Gateshead 10 as the number of overhauled parts piles up ready for fitting onto the tram’s bogies and body…

Photos in this post by: Phil Doran, Paul Jarman and Phil Smith

Recent Comments