Transport & Engineering Diary January 2026 Part 1

Welcome to the first post on Beamish Transport Online of 2026 – Happy New Year! As forecast in the review of 2025, there will be a lot to follow during the coming year, and already the quiet weeks over the Christmas break have yielded sufficient material for an early January blog post! Both are ‘holiday’ projects, but which will result in two operational objects from our industrial heritage, to be enjoyed at work well into the future.

Samson

Work on Samson has been progressing apace at Boston Lodge, so as with the last diary post, over to Matt Ellis to update readers on the work being carried out to overhaul Samson in preparation for its next ten-year operational stint. This post focusses largely on the retubing process – Samson has been tubed twice now in large and well-equipped engineering/boiler workshops, which has many advantages in terms of having the correct equipment to hand. We are very grateful to Matt and the Ffestiniog & Welsh Highland Railway for accommodating this work in their busy facility, and to the volunteer team of Matt, Ash, Will and Rachel who have assisted with this work so far.

Below: This first photo in the sequence of retubing Samson shows the tubes being annealed – heated to an orange heat, and cooled very slowly. This ensures that the material is able to work easily and isn’t prone to cracking when the expanding takes place.

Below: Having heated the tubes, they are plunged into a bed of lime. This insulates them for slow cooling, whilst also excluding oxygen, which minimises oxidation.

Below: Having cooled, the tubes are removed and the lime knocked out. The process is then repeated for the other end.

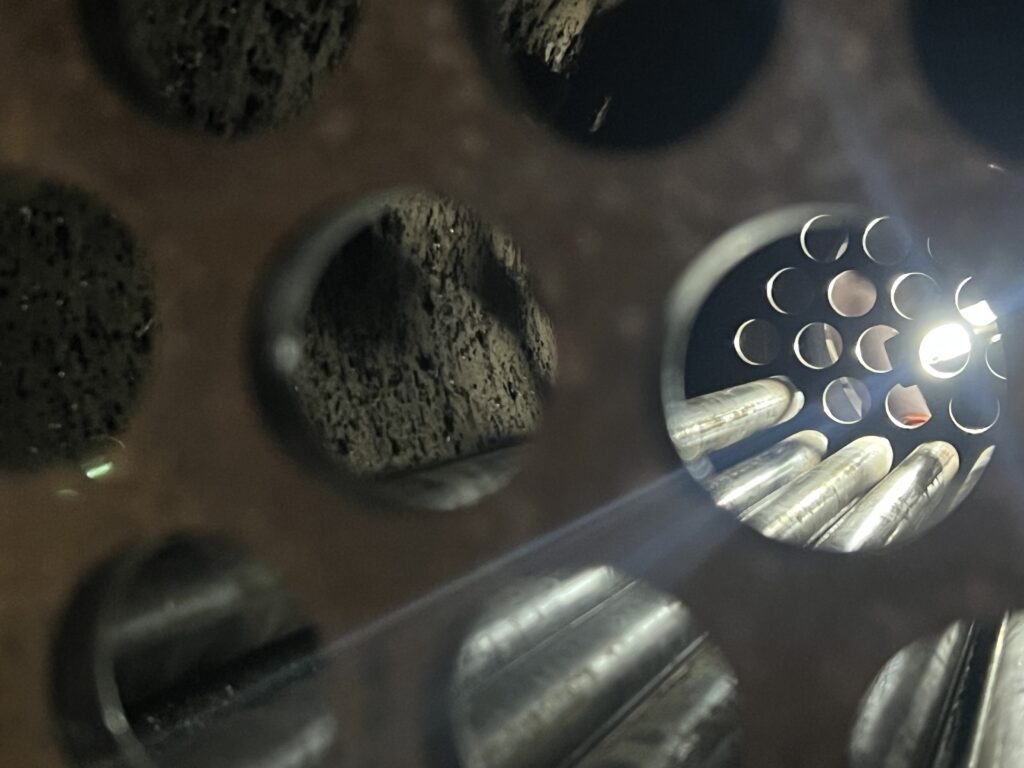

Below: The tube holes are shown being polished, to ensure they are free from rust and any imperfections.

Below: After annealing, any oxidation that did occur and the millscale from manufacture is cleaned off the tube. Both this and the hole cleaning ensure full steel-on-steel contact upon assembly.

Below: The boiler will be hydraulic tested with fittings on. Rubber joints have been made for this, but whilst all the right tools were out, the joints made from gasket paper were also made for use at a later date.

Below: The manifold and clacks were fitted with their temporary rubber joints. The blowdown has been refitted with its spindle pointing rearward ready for its new operating linkage. The blower take off has been blanked. The rear safety valve port will be used as the “water inlet” from the hydraulic pump.

Below: The tubes being inserted from the smokebox end, ensuring they head for the correct hole in the firebox tubeplate.

Below: Once the majority of the tube is in, manipulating it is tricky. A length of bar down the tube eases that and enables it to be lifted/directed for the firebox tube plate.

Below: The darker it gets, the closer we get to having all of the tubes in place!

Below: As the tubes arrive at the firebox tube plate, they can be caught and their steering into the tube hole improved. A simple gauge is then used to ensure the correct amount of tube projects out in the firebox. There is very little space to work in there!

Below: With all the tubes in and loosely gauged for length at the firebox end, we now set up for expanding. Step one, two tubes are double checked with the gauge by person one in the firebox. Person two then clamps them at the smokebox end to prevent them moving when expanding takes place.

Below: Meanwhile, person three lubricates the expanders. These are then handed to person one who seats them in the end of the first tube.

Below: Then commences expanding and a routine is quickly developed. Person one having seated the expanders, attaches the extensions to reach the air drill (attached to the crane to save repeated lifting). Person three then runs the drill to expand the tube. This is immediately repeated for the next clamped tube. The expanders are handed back to person two, who rinses them in degreaser, then cleans and lubricates for the next two tubes. Person one gauges the next two tubes. Person three clamps them. Expanders in…. and repeat. Whilst the small marine firebox causes difficulties, being able to get straight on to each tube is an advantage over conventional boilers!

Below: The process is repeated for the front, a little quicker as no clipping needed now they are tight in the firebox. If you really try, F1 pit style, it’s about 90seconds a tube!

Below: A closer view. Lots of oil to keep the expander clean and running easily.

Below: Video shows the process and the tube can be seen opening up. Three runs in with the expander to ensure the drill stalls in the same place and the tube is fully expanded.

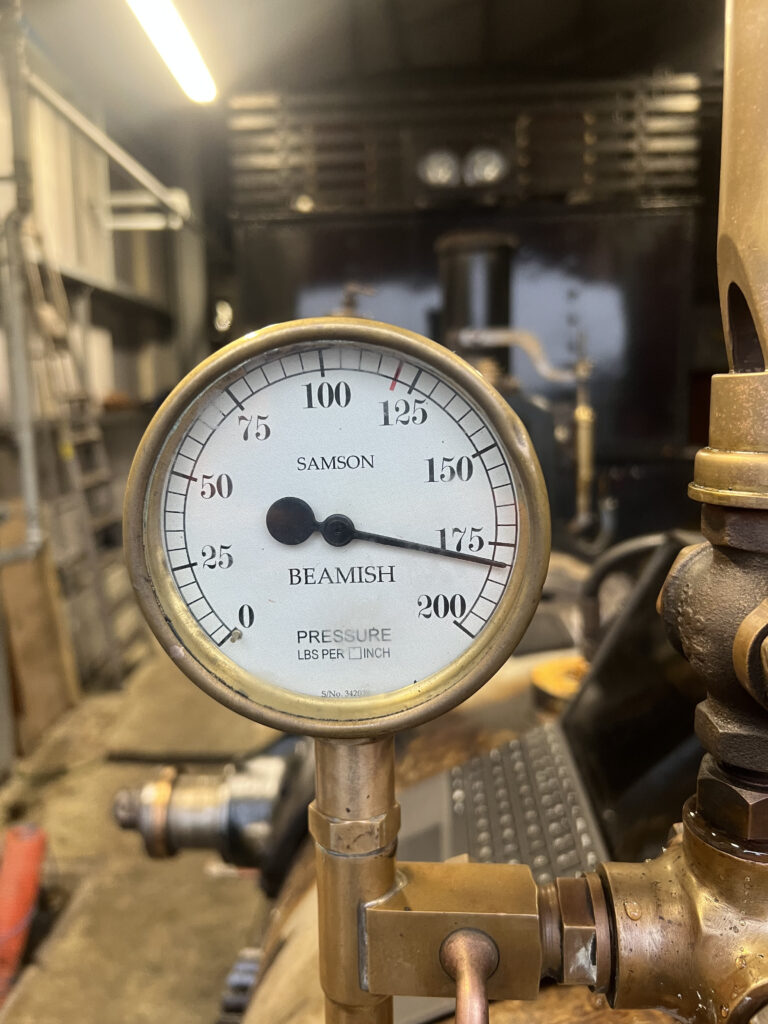

Below: With all tubes in and all fittings assembled, the moment of truth arrives. Filling with water, and then gently increase the test up to mains pressure. Various minor leaks on fittings to attend to, and one weep on a firebox tube end.

Below: A more substantial leak was through the regulator valve. None of us can remember how this was blanked last time and the blog photos from the last time we did it give the memory more questions than answers! The dome was removed and the faces all cleaned up, including that of the regulator valve face. New joints made and reassembled. The next test proved successful, with the hydraulic pump being used to raise the test pressure above what is available from the mains, meaning we now await the boiler inspector visit to witness it before a move is then made towards steam testing.

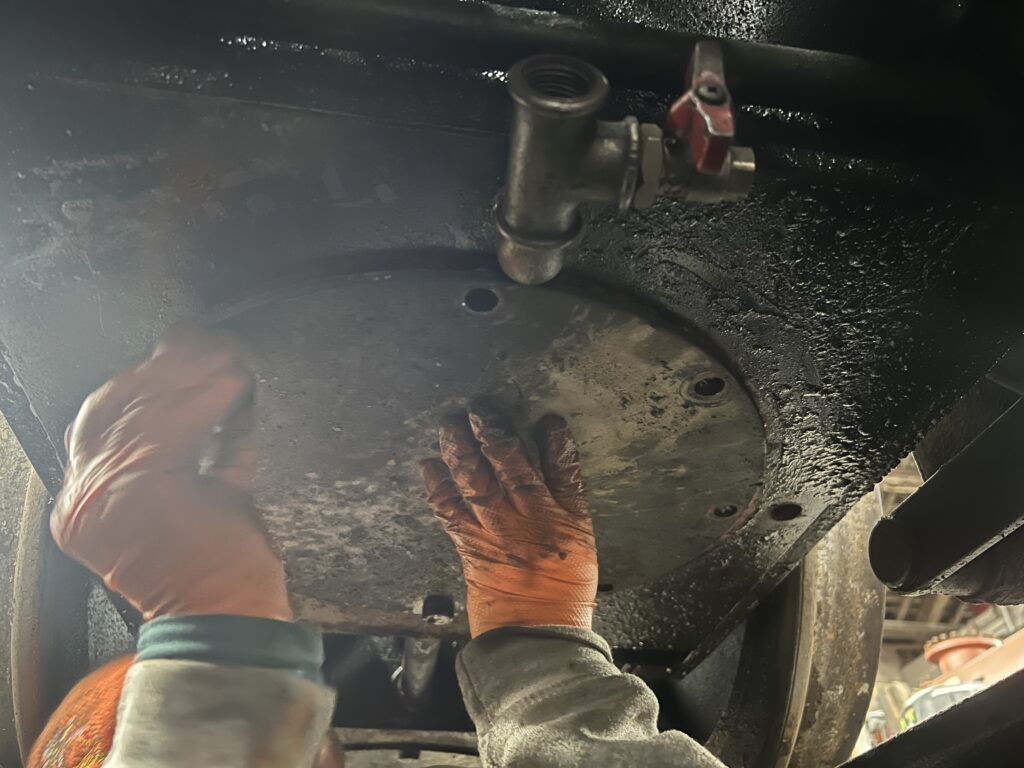

Below: The new take of for the injector water supply needed drilling, this being done with the aid of the mag drill (which can work upside down).

Below: With the new injector take off fitted and all the above work done, the manholes were refitted. The new injector take off has an upstand in the tank, so it doesn’t draw dirt and sediment from the bottom of the tank. As it will live in its new shed when back at beamish, with access to a pit, a T-piece has been put into the pipework with a small valve in order to enable tank and plumbing to be drained with ease, from the lowest point.

The remaining injector plumbing has been worked out with modifications to the delivery and live steam supply worked out for a future working session. The injector itself has the new water valve and immediate plumbing already fitted. More on this next time…

A successful hydraulic test was carried out for the insurance company inspector on the 8th January, enabling Matt to progress the reassembly and modifications in the next phase of work on Samson.

Lisbon 730

This tram has now moved to the main depot area as it awaits attention over the pit to drop one/both motors to establish a remedy for the gear misalignment that has been identified (see previous post). We had hoped to paint the tram into Darlington Corporation Light Railway livery, but there won’t be time for this in what is an already busy schedule and with the resources available. The paintwork does need some attention though, so an economy solution has been arrived at – which utilises the existing livery as the basis for recreating the Newcastle Corporation Transport scheme carried in the latter years of the NCT operation.

Below: This mock-up in Photoshop, crude as it is, shows the principle of the scheme. The white paintwork is also receiving attention as there was some localised rot in the frame that has been repaired, and it is a colour that often tarnishes as it ages in any case. The dash panels and the rocker panels will be painted in the deep plum/brown (as carried on Newcastle 114). What I couldn’t photo-shop was that the tram will receive new headlights, ex Oporto, that should better align its appearance with its Beamish colleagues. There are also some details int he paintwork that I wasn’t able to produce here, but you get the idea from this, of how the tram will look. A later addition might be advertising boards per 196, but there is absolutely no urgency for this.

Below: John has made a start on the paintwork, whilst work on the electrics carries on in the background. Additional handrails for the platforms (ex Oporto) have been sourced from our stores and are being prepared for fitting, to try and reduce any tendency boarding passengers have to grab the doors (which can move) rather than something stable and attached to the body. The dash panel in this view is seen in undercoat.

The priority in the team remains the assembly of Gateshead 10, but 730 will progress in the background. 114’s first controller is with a contractor for overhaul, after which the second will be tackled. Once they are complete, the tram can be re-commissioned, with completion of the paintwork earmarked for the spring (warmer weather).

Gateshead 10

Below: Assembly work on Gateshead 10 has been focussed on the brake components (linkages) beneath the body and the electrical components inside – including installation of the resistance, the interior contents of which are entirely new.

Some remedial work on 10’s paintwork is also being carried out, with a few cracks having appeared once it was settled onto its bogies. This work is challenging due to the cold conditions within the depot – a heated paintshop remains the dream!

Buses

Below: The engine has been extracted from Rotherham 220, which will enable some components to be removed and fitted to the new (to this bus) overhauled engine unit that is being assembled for installation in the bus. This is something of a priority project for the team, as having the bus back for Easter remains a goal.

Below: The replacement engine is being assembled in the machine shop, entirely from a dismantled/overhauled starting point. The crankshaft and connecting rods have been installed, likewise the prominent lubrication rail (in copper), seen here.

Tramway

Below: Work on the Tramway this winter is in four distinct phases:

- Foulbridge bus turning circle

- Sleeper renewal between the Town and Pockerley

- Rail-welding on the outer-circle Town curves (in High Street)

- Overhead Line Equipment renewal (ongoing)

This represents a very substantial investment in six figures this winter alone. The work at Foulbridge began with removal of the rails, for one length, to allow a new track base to be installed and new sleepers placed – upon which brand new grooved rail will be installed. This will enable this area to be ‘filled’ and, with work on the adjacent depot yard area, we will gain a large turning circle – this enables the Colliery Shuttle bus service to turn, and go ‘right way around’ what is effectively a roundabout, will stop the process of having to use the pavement as part of the arc the bus traverses in order to turn and will be large enough to allow all of our buses to operate the Colliery Shuttle if required.

Below: In the absence of a dumper truck on hire, the Leyland Cub tipper has been earning its keep on spoil removal and ballast delivery duties.

Annual Mileages

As ever, the annual vehicle mileages for buses and trams make interesting reading and show how intensively used the vehicle fleet is. Some key takeaways from it are:

- Total bus/tram fleet mileage is: 47,936

- Tram fleet (using four trams and with the tramway closed in Q1 of 2025): Total 16,305, broken down as follows:

- Sheffield 264 5752 miles

- Sunderland 16 4637 miles

- Blackpool 31 3531 miles

- Oporto 196 2385 miles

- Highest individual bus mileage was the Wheelchair Accessible Vehicle, Crosville 716 – 9895 miles. The B-Type was second with 7728 miles accumulated. Third place was visiting bus (which has been resident on a protracted stay with us, and has been of great help in maintaining the service) Scout Motor Services 18 – 4038 miles.

- The bus mileages do not include the North East Bus Preservation Trust vehicles, Sunderland 13 and 139, nor any of the visiting buses for Fares Please! or the Halloween and Christmas evenings.

- We have seen a decline in mileage on the tramway, and increase of bus mileage – the latter being 66% of the total – which gives a nice divide of 1/3 Tramway, 2/3 bus operation.

- A rough calculation suggests that the cumulative fleet has circum-navigated the museum site around 33,000 times in 2025! That’s a figure that takes a little comprehending doesn’t it!

Photos in this post by Phil Doran, Matt Ellis, Paul Jarman and Ash Wiseman

Hi Paul, Thanks for the update on trolley buses and 50s town domestic garages. The bus shelter going in at the Pockley stop should prove to be very useful will there be seating inside the shelter like the tram shelters?

Of course there are other bus stops that would benefit from shelters too maybe in time that could happen.

One job that did not get on your to do list is the black shed being joined to the rest of the colliery rail network and yes it may be some time before it happens but do put it on the list of jobs to do.

It has been in the railway press that beamish is getting a metro train 4020 what are the plans for it.

Regards Gary

Hi Gary

Re your queries:

There isn’t any seating planned to go inside the bus shelter but we may consider adding some at a later date. The work was largely grant funded, so anything extra would come from our own resources.

The plan to link the black shed in the Colliery by rail is indefinitely on hold. There is no real need to do so and the ground levels to join it to the system would be intrusive and expensive. We have managed well without it so I can’t see it being an avenue of work I would want to pursue at the moment. There is a thought we might complete a stub to the end of the turnout to make for loadning/unloading adjacent to the shed (when low-loaders are needed), but again, this isn’t a particular priority for us.

Re the Metro train – I am not able to comment on this at present as the situation is still under discussion.

Best wishes

Paul

an answer to the above would be good