T&I News 18 2017…

Paul has been enjoying a few weeks away from the office so a different author for this post. The school holidays are still in full swing; so far this August we have welcomed over 77000 visitors! Keeping the basics going at this time of year is a full time task for the Site Maintenance Team and not all of the jobs are as pleasant as others, but more on that later.

Even though, the Maintenance, RHEC and Buildings Teams still find time to keep the various projects going.

Regular visitors may have noticed that the Co-Op building, in the Town, has been without its sign for the last few weeks. This has been another victim of poor quality plywood, so a rebuild was the only answer. The new birch ply boards and frame work have been fabricated by Tony in the RHEC. Whilst Ryan, from the Maintenance Team, after applying several layers of primer, undercoat and top coat has turned his hand sign writing.

Ryan adds the lettering

A refresh for the Wheat-sheaf logo

The sign framework

The old sign on crumbling plywood

The Painters and Handymen are in the process of moving to a new, larger, workshop with more work-space and vehicle access.

New Workshop

The Morris Commercial is now receiving the finishing touches to its new body. After a full repaint it is now with Chris, in the Fabricating Shop, for the addition of a rear step and doors. It will hopefully only be a matter of weeks until the Morris will be seen on site.

Chris adds the frame for the rear step

The Galloper overhaul is moving along well. At Beamish Rebecca continues the painting of the horses. Off-site the Centre Truck is reciving some much needed tlc at Rundles in Lincolnshire. After a visit there last week, to see the progress, it is apparent just how much work is needed.

The Cheese Wheel, which houses the main running gear

The main running gear, housed in the ‘Crows Nest’, is unseen by riders but is the very heart of the ride. Much of the equipment is original to the 1893 ride; although the Centre Truck is new the gearing was transferred from the old truck to the present one. 124 years of work has taken its toll so a new set of dolly gears and bearings will be manufactured and fitted. However, not all of the new parts new. Rundles, just happened to, have a spare Cheese Wheel from a previously dismantled savage ride. This will be joined by a new Cheese Gear and will maintain the integrity of the ride, whilst making it serviceable for a good few years to come.

Considerable wear to Cheese Wheel and Swift supports the Cheese Gear can also be seen below

The worn dolly gears

The wear can be seen on the Cheese Wheel. What once was round is now flat.

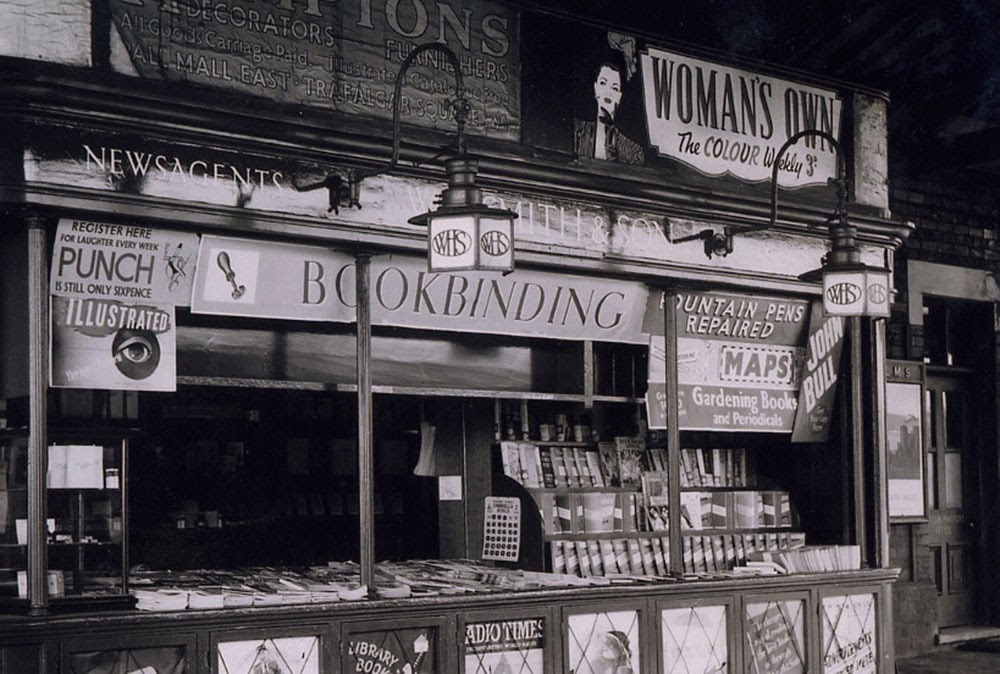

It’s not just the staff who have been busy. Peter, on of our RHEC volunteers, has been creating lamps for the Horse Tram project and the W H Smith kiosk. The W H Smith lamp has been created from scratch, with only a few photos for reference. The addition of frosting to the glass and the WHS logo will add a nice finishing touch to the kiosk.

The inspiration for the lamp

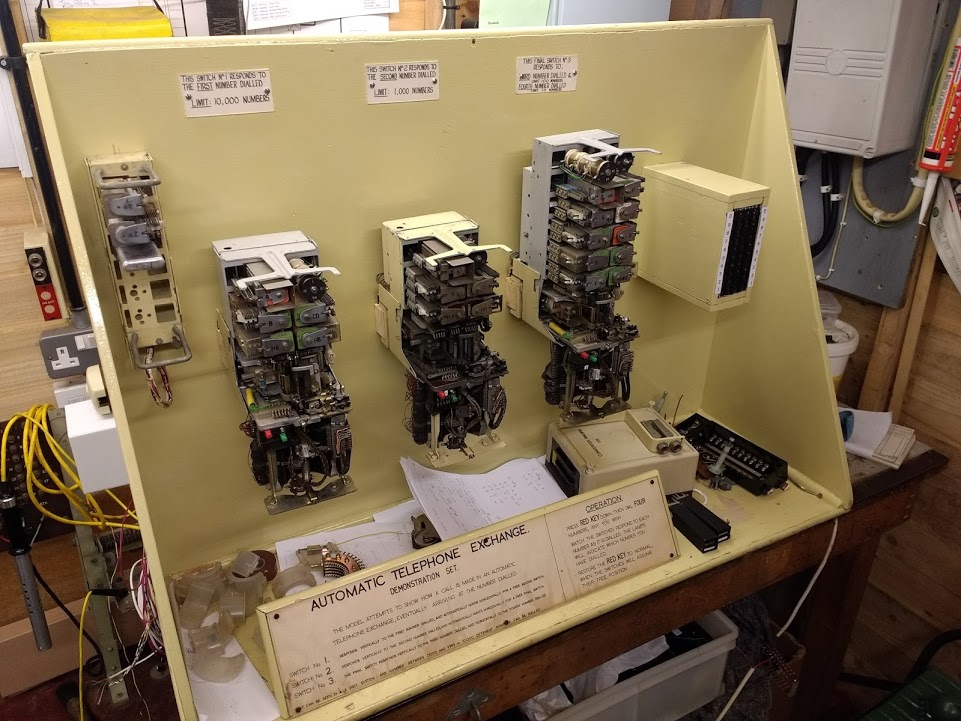

The Beamish Telecom group volunteers also remain busy with a steady flow of requests for new lines and extensions. Of the 100 lines available over 80 are now in operation. Unfortunately the exchange is not accessible to visitors to see the work the group carries out. However, the group are in the process of adapting a demonstration exchange to go on show in the museums Open Store. The demonstration set was constructed by the GPO as an educational tool, to show how a telephone number was dialled. The addition of two handsets will allow visitors to dial a call, and see it travel through the exchange, and talk to the person at the other end.

The Demonstration Exchange

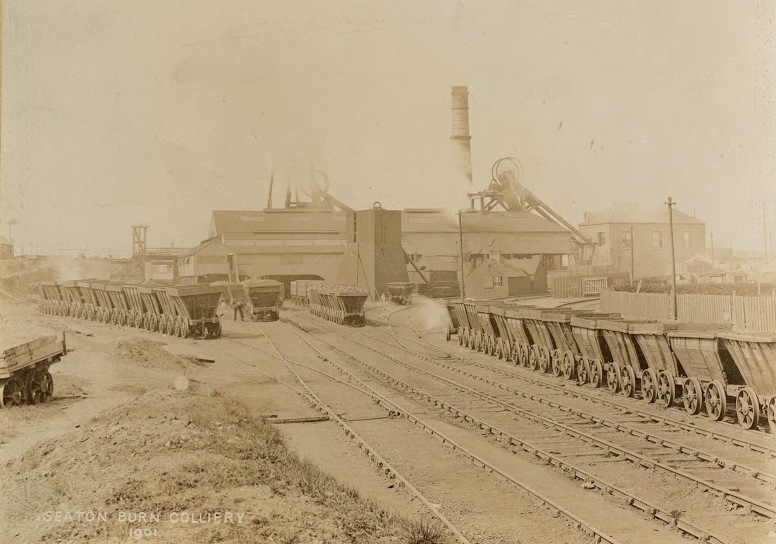

Over the past couple of weeks work has started on the small engine shed, in the colliery, to house the Brightside Engine. The engine will power a fan for the colliery forge; with the possibility of other belt driven additions in the future. The construction is not based on a particular shed but takes its inspiration form several colliery buildings of the 1850-60s; constructed with the plank and lat method. The picture of Seaton Burn Colliery shows just how much was built from wood, with only the winding house constructed from stone. Some plank at lat buildings can be seen to the right, in the shadow of the heapsted.

An amalgamation of new and reclaimed parts

Over the coming weeks the roof will be added and the internal fit out will make the shed ready to receive the engine. There will also be space to display the Steam Mule a water pump. Generally only seen at events, the engine was also constructed by Dave Young who has carried out the overhaul of the Brightside Engine.

The Brightside Engine

The Steam Mule

Even the waste timber has been put to use by Ian the Colliery Supervisor. High-rise for birds.

Staying on a shed theme Shaun and the Buildings Team have been building a 1950s garden shed. Although, probably, the smallest it is the first of many 50s building to be constructed over the next five years. The shed will eventually be displayed housing some of museums motorbike collection.

And finally, as alluded to at the beginning, not all of the jobs tackled by the team are as pleasant as others. 750,000 visitors a year amounts to a lot of toilet flushes! As the museum is not connected to the main sewage system we have to take care of the problem ourselves. This comes in the form of three large treatment plants and a collection of small septic tanks. Unfortunately, from time to time these plants need maintenance and with the recent failure of a gear box there was nothing for it but to brave the smell and get to work. Brain, Bob, Danny and Ian, over two days managed to salvage a gear box and get the large agitator turning again. This is one of those behind the scenes jobs that really is essential for a comfortable visit to the museum.

Sewage treatment plant

Hi Jonathan, Long and interesting post, the Gallopers look more complicated than I thought . Has there been a start on any buildings in the 1950′s remaking Beamish Project ?

Ray Butler