T&I News 35 2021…

The blog resumes following a short hibernation (as I was on paternity leave!) with an update covering the period I was off. Matt kept notes and took photos throughout the period, so whilst this news has been a little while in coming, it picks up where the last post left off, and takes us through pretty much to the close of our calendar year, 2021 (with one more post to follow, covering the OLE inspections, and if I have time this year, a review of 2021. If not before Christmas, I’ll write this in January, when, who knows, we might be operating under lockdown restrictions again… Over to Matt for the photos and his captions:

Below: Elf houses for the Christmas festivities. Built by a RHEC volunteer (Peter) and then Rebecca has painted them. Particularly impressive is the school, with individually painted stones.

Below: The Armstrong Car is used at Christmas with the roof off in order to convey Santa and Mrs Claus around the site, whilst stopping to chat or have photos taken. The tramway team decorate and provide the drivers for this operation.

Below: The Armstrong Car is used at Christmas with the roof off in order to convey Santa and Mrs Claus around the site, whilst stopping to chat or have photos taken. The tramway team decorate and provide the drivers for this operation.

Below: The B-Type bus is now back in service, having done a few days and evening events now. It’s great to see it back in service and is all the better for the attention it has received from the team.

Below: The final top deck seat from the Daimler replica, this one is at the top of the stairs and is sign written. Here the chalk markings are applied ready for paint. The bus was complete for the Christmas evening events. The lower deck will be similarly treated in the New Year.

Below: Dan has completed the spikes for the Lineside Worksite protection boards, so these can go into use in the New Year.

Below: A very full bus depot. For the Christmas evening events Go North East have kindly loaned us the Routemaster again. This was a bit of an insurance policy against any failure of our own fleet and to provide useful additional capacity. Use of the tramway for the busy evening events would not provide useful capacity as their lap times are high whilst the full tramway circuit is not available. With our own fleet plus the Routemaster six buses have operated at each of the evening events. The frequency between vehicles being on average around the 6 minute mark, but often much less, proved very efficient for moving the volume of visitors. In this view everything in view was operational for the events, with J2007 in the workshop (for storage rather than work) and available as a spare to 716.

Below: The Landrover 2A came in with a slipping clutch. The clutch was worn out, so has been replaced. The MOT for the vehicle is almost due, so other work has been carried out at the same time, which has included new rear springs, old and new seen here. The petrol tank also has a minor leak, and as new ones are not expensive this was also replaced. Some platework has also been replaced around the drivers foot well. It has now had its MOT and is back in service with the Gardens team.

Below: The Landrover 2A came in with a slipping clutch. The clutch was worn out, so has been replaced. The MOT for the vehicle is almost due, so other work has been carried out at the same time, which has included new rear springs, old and new seen here. The petrol tank also has a minor leak, and as new ones are not expensive this was also replaced. Some platework has also been replaced around the drivers foot well. It has now had its MOT and is back in service with the Gardens team.

Below:The waggon way train has had all the brake cylinders replaced recently. The vehicles in the train with handbrakes require a method to enable the hand and air brakes to apply independently. The original clevis allowed the piston rod to move within it, coming up against a stop to apply the brake. This has worked but has caused excess slack and shortened the life of the brake cylinder. The link was therefore modified to be fixed on the rod, and allow the brake shaft pin to move within slotted links on the clevis.

Below: Whilst we wait for the welding contractor to carry out some coded work on the wheelsets for Gateshead 10, in to carry out test pieces and analysis, the axle boxes and horn stays have been cleaned up and spray primed for protection. They will go to the paint shop for Rebecca to brush prime, undercoat and gloss.

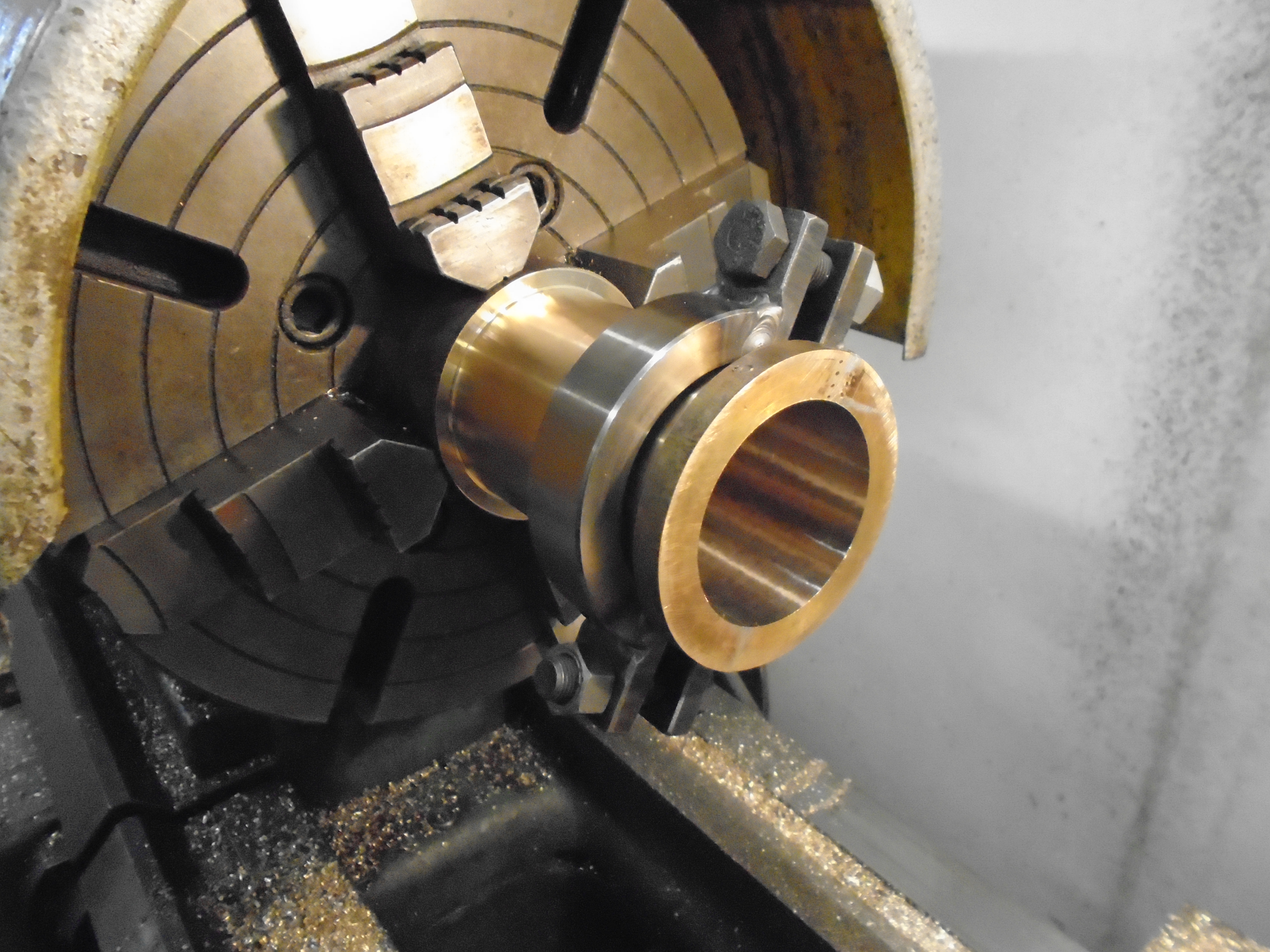

Below: With work on the wheelsets and axle boxes for Gateshead 10 paused, Don and Zoe have picked up the work on the track brake system. Some work had been done on this in the past to the bearing pedestals. Don picked up the bearing pedestals themselves and has skimmed the bores to remove some hard spots in the castings, generated by previous repairs having steel bearing shells welded in. Zoe is machining the new split bronze bearings to fit the pedestals.

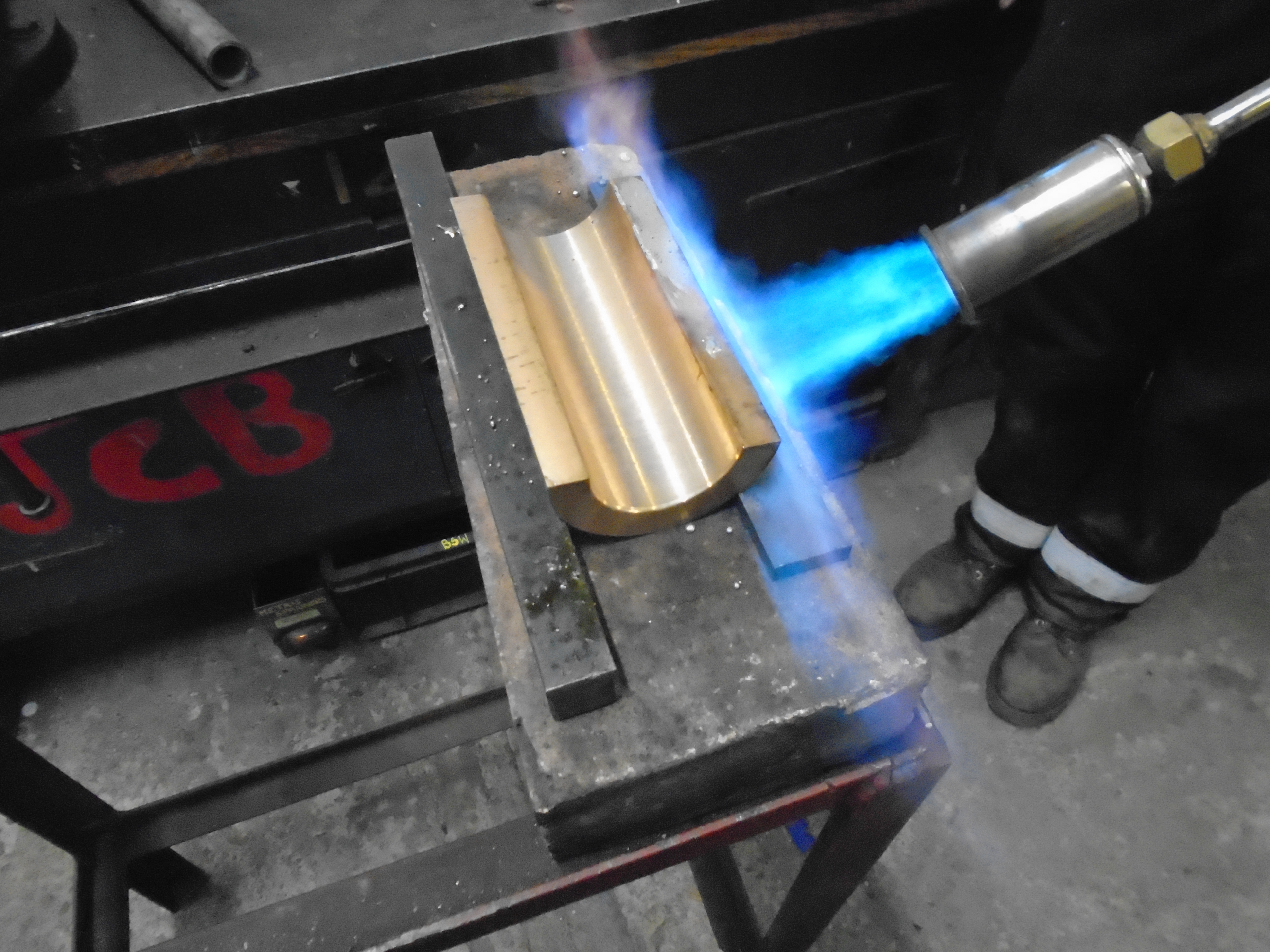

First they are bored out in the lathe to remove a slight excess of material. They are then set up in the milling machine, and the slitting saw used to split them most of the way, some material being left to support the top half whilst the cut takes place. The cut is then completed with the hacksaw. The mating faces are first tinned and then soft soldered together.

Machining of the outside diameter and finished internal bore is then completed to fit each journal and bearing pedestal. Various fixtures have been made to support the bearings whilst they are being machined as the wall thickness on completion is actually quite thin, and the bearings themselves are also quite long. The fixtures also provide additional protection to the machining forces splitting the bearings along the solder line before we want them to be! The bearings can then be split by melting and cleaning away the solder.

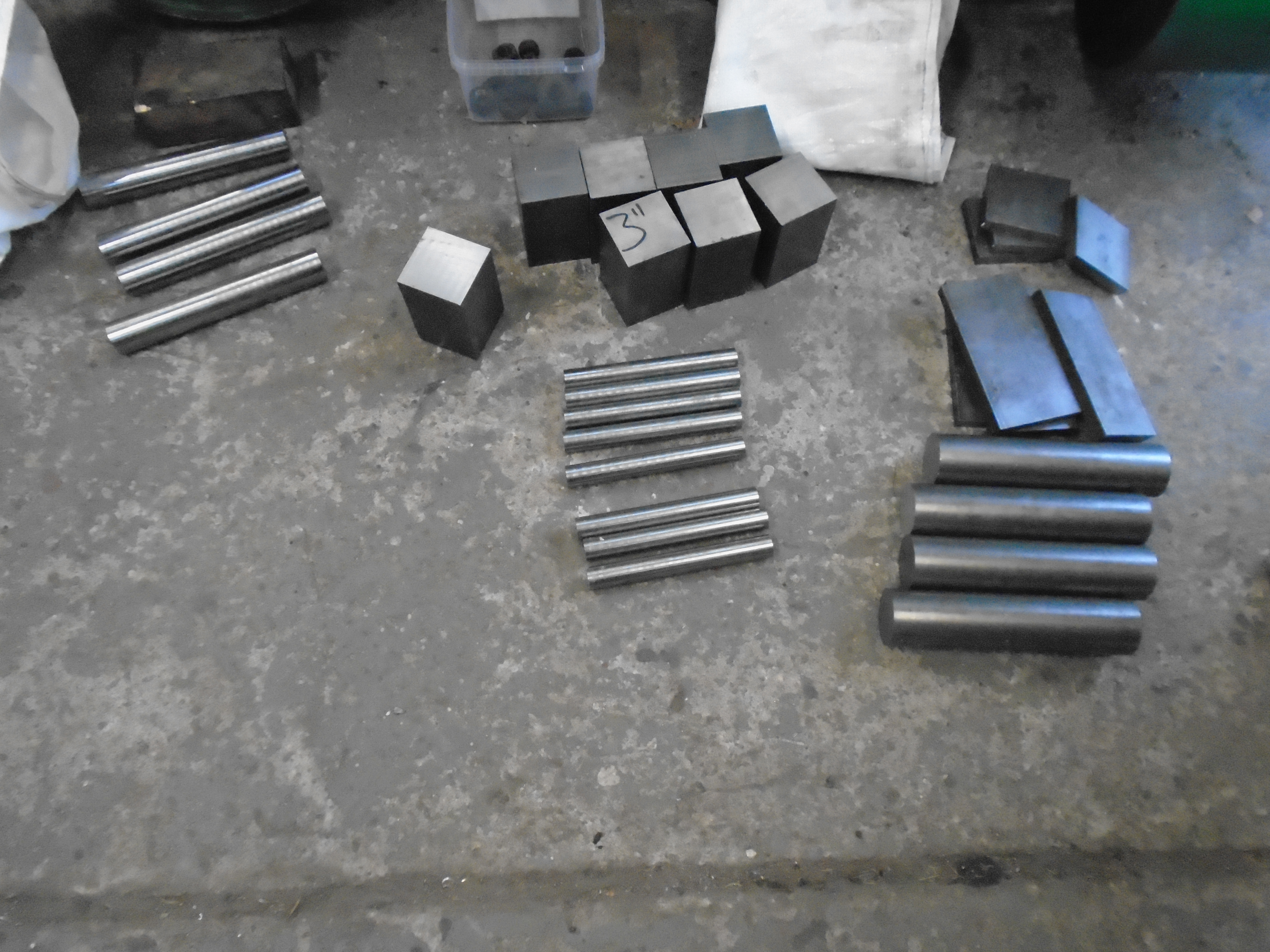

Below: These raw materials will form the links, pivots and wear plates which keep the secondary suspension bolsters in situ in the trucks whilst also permitting limited movement in certain planes. To enable set up, the bolsters have temporarily been clamped up in the trucks. We’ve used a local firm to laser cut the main links for us (delivery of these is scheduled for this week), from a drawing created by the team. This both saves material and time, for what is a fairly simple part would be time consuming to produce here, particularly when there are eight to make!

Below: Antony has progressed most of the steam fleet to the point where they are ready for annual boiler exam. To access the firebox on Glyder its placed over the pit and its brake gear and ashpan removed. The boiler inspector spent two days with us and completed all the cold exams with the exception of Puffing Billy, which is in service so will be done in the new year. The boiler inspector also brought two trainees, our varied fleet offering a range of boiler types and sizes to see, the steam mule being a good example of the smaller end of the spectrum, but with vertical fire tubes (as is coffee pot).

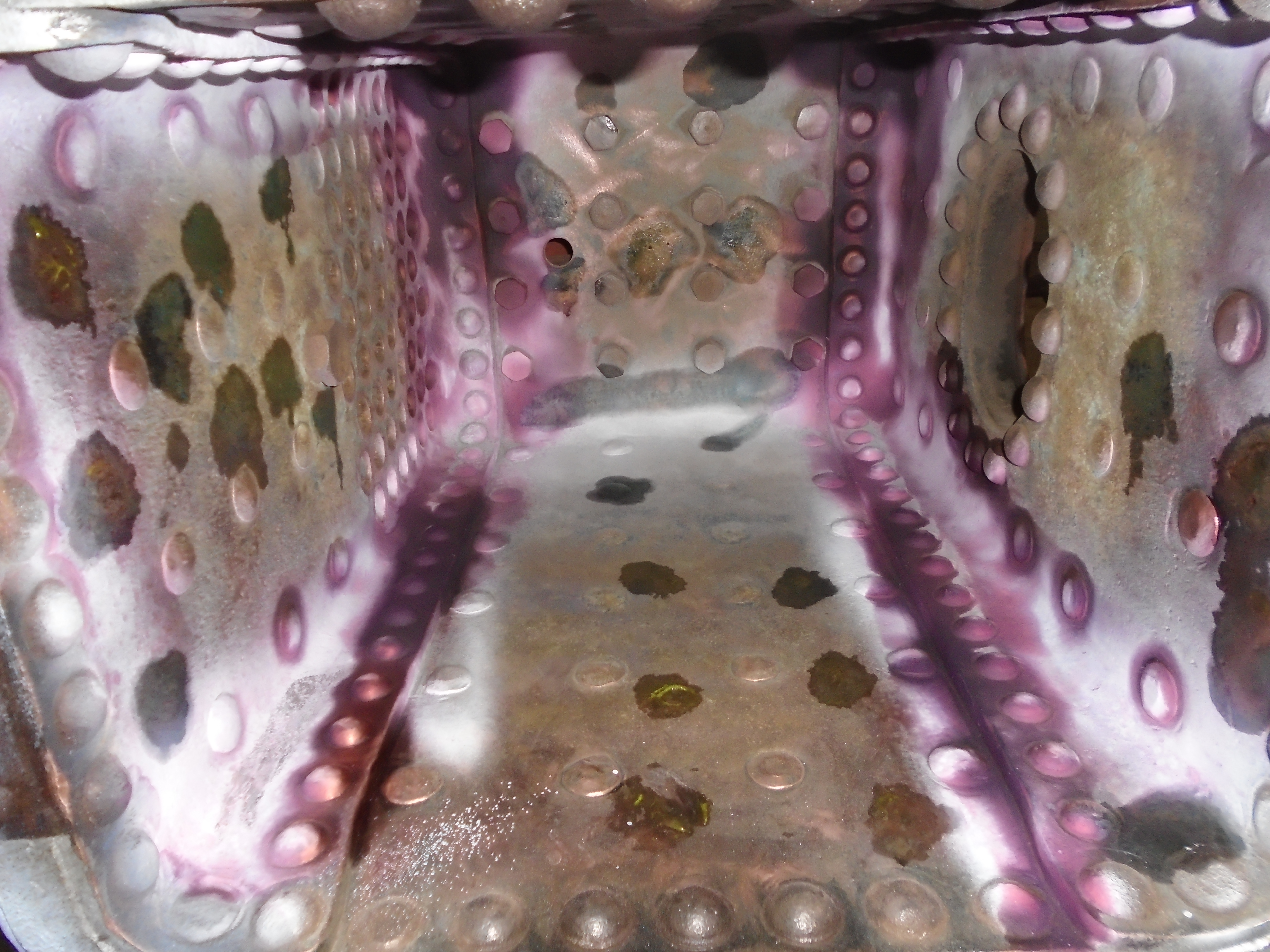

Below: The final cleaning up of the firebox on Kerr Stuart 721, the ex Dundee Gas Works locomotive (thanks to Chris and his forced air feed helmet) to enable Non Destructive Testing (NDT). The NDT work was undertaken by British Engineering Services using Magnetic Particle Testing (MPI) to examine the steel plates for any cracks, particularly where plates are flanged or areas of stress. A similar procedure of Dye Penetrant Testing (Dye-Pen) took place on the inner firebox, MPI being unsuitable here due to the copper used for the construction of the inner firebox.

Ultrasonic testing of the plates was also undertaken to measure plate thicknesses all over. Additional thicknesses were measured at areas where pitting is visible. Whilst the boiler inspector was with us, repairs to enable a return to service were agreed and will be recorded as part of his survey and our methodology for proceeding with the repairs.

Below: This is not just any nut. Manufacture of this marks the start of Dan’s apprentice project. His project is to build (from scratch) the rail chassis for the Crewe Tractor. We obtained the drawings for these First World War machines (built by the LNWR at Crewe) from the NRM archive some time ago with this project in mind. The first components Dan will make are the turnbuckles and straps which both link the rear road axle to the rear rail axle and adjust the drive train length. Looking forward to 2022, both Dan and Zoe will be regularly working on their projects (Crewe Tractor and 721 respectively) with Chris and Don continuing to mentor them. Paul will cover the project in more detail as it gets underway. Incidentally, having covered quite a few miles, the Ford Model T component of the Crewe Tractor is also receiving attention, with an engine and gearbox overhaul underway.

Paul, firstly congrats! on needing paternity leave, and thanks for completing another year of very interesting and informative posts. Hope the new year works out better than the last & that you and the team get to progress all the projects that are planned. All the best.