T&I News 11 2019…

Most of this post is focused on the operation of buses at Beamish – including the rapid construction of the new depot and workshop as well as the purchase of a new motorbus for use here at the museum…

Bus Depot

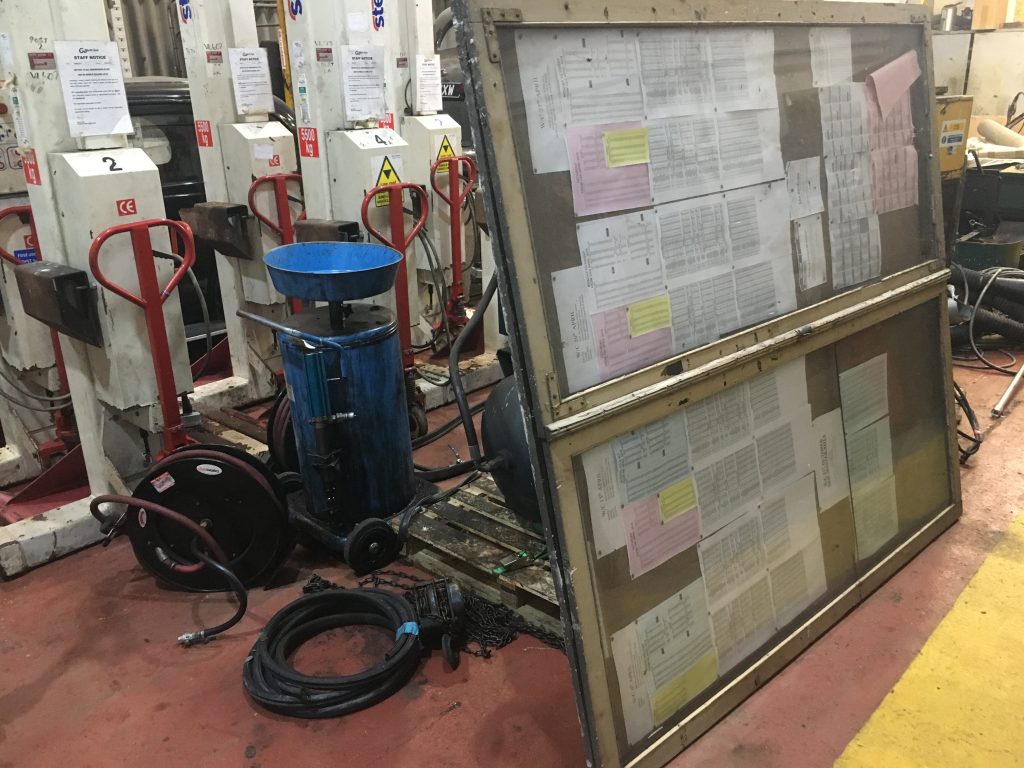

The depot is making great strides towards completion, and the planned fit-out has also benefited from the recent relocation of Go North East’s Stanley depot to a new site (and bespoke modern building) in Consett. With the support of Go North East, one of our major business partners (and who have also financially supported the depot construction) we have been able to obtain two sets of modern column lifts, numerous stands and tools, a compressor, LEV (Local Exhaust Ventilation) system and numerous other items including the original depot noticeboards. These will all be utilised within the workshop and depot and have been a colossal contribution to the facility, meaning that we will have a 21st century workshop to sustain our historic vehicle fleet…

Below: A selection of the items that we have been able to obtain at a very reasonable rate for restoration/reuse within the new bus depot. Russell Walker, who looks after the buses and historic vehicles at Beamish, has been instrumental in making the links to obtain these items (from his former employer) and has been fairly determined in the acquisition of equipment that will stand Beamish in good stead for years to come.

Below: As well as a service pit, we will also be able to lift vehicles using these column lifts. We have two sets here, and they will replace the current car lift (the existing vehicle workshop will become a fabrication shop in due course…) as well as provide the means of lifting two vehicles at a time within the workshops if required.

Below: Outside, the construction of the depot is proceeding apace, with the steelwork being erected this week. Here the shape and size of the depot and workshop can clearly be seen. Yes, it would have been even bigger, but for the need to respect the allocated budget for this element of the Remaking Beamish project!

Below: These views show the depot end of the building…

Below: … whilst these views show the workshop end, which has a lower floor to cater for the falling ground levels (and also gives a usefully taller workshop space). The steelwork was completed on Thursday, with the cladding, internal blockwork, pit and floor to follow next.

Darlington 304

Below: We have added another bus to the collection, in the shape of Darlington Corporation Daimler CVG5 Registration 304 VHN. The usefulness of Rotherham 220 has exceeded our expectations and the opportunity to purchase a similar vehicle, in full working order and with a local provenance was too much of an opportunity to miss. There is also a great benefit from the overlap in spare parts the two buses will require, which assists the maintenance team in their work.

It was new to Darlington in 1964 (so very much at the edge of our 1950s period, which does, to be curatorially honest, stretch from c1945 to the mid 1960s in reality!), and was their fleet No.4. The chassis is a Daimler example, with the coachwork by Charles Roe of Leeds (H33/28R).

A photograph of 304 in service can be seen here: https://bryansmith.smugmug.com/Bus-Operators-UK/Bus-Coach-Operators-C-D/Darlington-Transport/i-H7CQkMH/A

The bus was delivered to Beamish on the evening of the 24th April and will be commissioned for service at the museum – a little ahead of the completion of the new depot but ideally timed to assist Rotherham 220 with the relief duties it is currently performing on busy days. The motor buses can circulate far faster than the trams, and as mentioned above, 220 has proved to be an ideal vehicle for busy start and ends of the working days when moving visitors from and to the main entrance is the transport team’s priority. We had looked at other options for motor buses for this work, with 304 coming along at an ideal time for this role.

Below: 304 during its first inspection by Beamish staff.

Below: A selection of views of 304 after arrival at Beamish…

Other news…

Below: Sheffield 264 has been reassembled and is currently undergoing testing prior to re-entering service. This will take the available number of working trams to seven – a rather different situation to last year!

RHEC

Below: The ongoing saga of the gallopers continues, with more and more work being identified and thus a longer delay to their erection at Beamish being the result. The elements within our control are, however, shaping up well, with the centre engine nearly complete and the horses overhaul and repainting nearing the end of what has been a very long (nearly three years!) process to restore them! To house them in the future, one of the packing trucks that came with the ride is at the RHEC for overhaul and the fitting of a roof -this will then enable safe storage of the horses in the future as well as creating another authentic element of the fairground in the form of the truck itself, which is being tidied up and painted to reflect Sally Beach’s ownership.

Rowley East

Below: The replica crossing cabin has now been installed at Rowley East and work continues to blend it into the surroundings, including a small allotment. The internal telephone is yet to be relocated into the cabin, but already the potential of this viewing point is apparent, with some new angles for photographers and a pleasant area to watch the trains as they arrive and reverse. More landscaping to the rear of the Town is planned in due course, with additional tree planting to screen passengers from the ‘service’ end of the stables and Masonic Hall. We also plan to extend the loading pad siding in order to be able to unload rolling stock in either direction (no more wrong-way round locomotives!). The gateway will also be improved, always being something of a tight spot for low loaders.

No name has been chosen yet, though I like ‘Rowley East’ to suggest its proximity to Rowley, but at least some separation!

Steam Elephant

Below: Steam Elephant’s boiler overhaul continues and draws towards completion. The chimney is having some work to repair corrosion that inevitably occurs in this aggressive environment for metal plate – the second photo shows the patch in place with the original material that was cut out, to the right. The locomotive will be due a much needed mechanical overhaul in the next twelve months and is likely to be one of the first beneficiaries of a new workshop space that we intend to create to the rear of the tram depot (on Road 4/5). After this Puffing Billy will be due a similar process and we are considering replacement of the timber frames at that stage as they have an increasing number of faults that are becoming time consuming to remedy. We may consider structural timber for this, suitably aged on visible surfaces, or even the same method as Steam Elephant, with a composite steel and timber construction. On Billy it will be harder to hide the steelwork, so this will be a challenge for us to face in the next few years…

Below: A before and after photograph showing the heavily coked up blastpipe nozzle – the reduction in internal diameter is readily apparent in the first view when compared with the second!

Great to see progress on the bus depot and the acquisition of Darlington 4, which gives a great variety of transport around the site now. Out of interest, how many buses will the bus depot house when completed?

Also, are there still plans for the trolleybuses to be housed in the tram depot when the bus depot is built?

Thanks

John

Paul, if you were ever in need of any material as an example of how important the buses were in getting the masses (workers, the public & school pupils) transported in the north, there is a great bit of film from 1946 on the BFI’s website

(https://player.bfi.org.uk/free/film/watch-just-billingham-no-7-1946-online) starting around 3 minutes in. An informative and light-hearted piece.

Regards

Great to see that the steam elephant is getting nearer to a return to service, however what about the forgotten wagon way loco Locomotion no 1 are they any plans to over haul it?

Hi Gary. Locomotion is far from forgotten in our minds! It remains on display at the National Railway Museum’s Shildon site. I am not presently able to give you any further details regarding its potential future return to steam, though of course the S&D 200th anniversary celebrations in 2025 are not far from anyone’s minds… Best wishes, Paul

Hi Paul,thanks for the reply ref locomotion.

how about Rowley junction or Rowley town junction instead of Rowley west? a railway type seat or bench would be a useful addition so people can chill and watch not only the trains come and go but also the trams buses and other road vehicles that go past regards Gary