T&I News 25 2021…

This week saw an important event take place, albeit in the hours before the museum opened on Tuesday; namely the first tramcar movement (outside of the depot environs) since March 2020. This marks an important step on our road to recovery, and whilst the return of the tramway will be a phased and occasionally frustrating process, we have now made a start (and after a lot of work behind the scenes).

Friday was also one of Coffee Pot’s running days – the next will be on September 10th. As well as Coffee Pot No.1, No.18 and Glyder were in steam. The buses were busy with 4, 220, 716 and the D-Type in operation across the day – which felt like quite a lot of transport and a nice reminder of busy days in the past.

Tramway

It’s been a while since we’ve had a tramway heading on the blog! We now have activity on the tramway itself, whilst work on Gateshead 10 is progressing well as the extensive reconstruction of its bogies (and their running gear) continues. More and more work is now being tackled – with our own engineering team, the previous list of work has been expanded to improve other areas of the bogie operation and standardise components both in size, but across the tram, ironing out a lot of ad-hoc repairs and modifications that were added through its long working life (Gateshead, Grimsby and Beamish).

Below: Within hours of returning to work after a lengthy sojourn away from the museum, Brian and Ian pose with 196, seen here at the Main Entrance stop. Monday was spent preparing 196 for action (you may recall the electrical testing as completed a while ago).

Below: The next milestone – Pockerley. This also entailed preparation and inspection to insure the electric token system (ETS) was functioning correctly, work completed in recent weeks by the Beamish Tramway Group volunteers.

Below: The furthest extent of the test running for this week was the concrete crossing adjacent to the 1950s Welfare Hall. Beyond this there are some outstanding track maintenance tasks to complete before the final few yards to the bakery is signed off for use. This will also include reversing the bias of the facing point, entering the long Town section, so that passengers alighting from terminating tramcars do no do so directly onto a curb and into the path of the buses. Two more staff return next week, and begin their refresher training, and will be using 196 and Blackpool 31. These workings are largely taking place whilst we are closed, because of the obvious questions that otherwise arise from visitors who wish to use the trams as transport. We are still working to a public resumption of service on September 4th…

Engineering

Below: Chris and Dan have completed the machining of the new bottom tank for the Fordson N tractor – seen here with the damaged original. There has been a substantial amount of work to complete this – a moment’s lapse committing the team to a lot of expensive and time-consuming work. However, the repair has been terrific experience for Dan (one of our two apprentices) and the new tank is undoubtedly a far more durable component than the original!

Work on the B-Type bus continues. Russ, Alan and Chris have got to the bottom of the very heavy clutch. Some of this is a hangover from when the new engine was put in a few years ago, and the way that it is mated with the old transmission. Various spacers are required to ensure smooth and reliable clutch operation, and hopefully this work will consign some of the regular operational faults and adjustments the team has had to make, to history. It does show how nothing is ever straightforward, and that even the replica vehicles require considerable engineering resources behind the scenes, in order to accomplish what sounds quite a straightforward job (i.e. replacing the engine, re-fitting the clutch, etc.).

Below: Firstly, some tooling has been made to assist with the work. An attachment for the trolley jack to take the bracket which is used for lifting the transmission in and out was fabricated. Usually the bracket is mounted on the pit transmission jack, but to retain pit availability, this work has been done on the level using the trolley jack.

Below: The spidery device mounted onto the trolley jack.

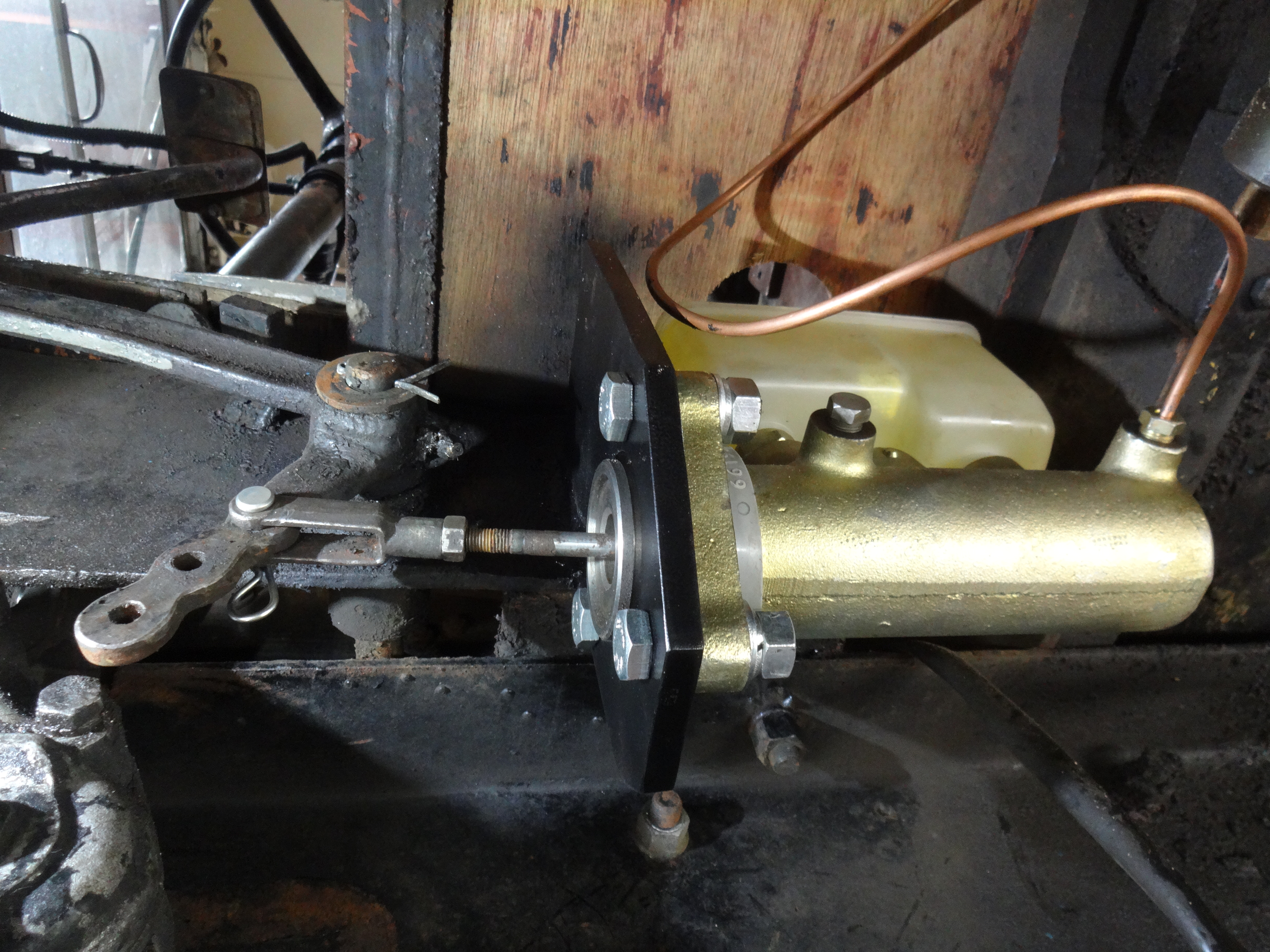

Below: The new clutch master cylinder, complete with a new bracket (the steel section to the left), to enable it to be mounted to the bus chassis.

Below: A view of the underside of the B-Type, looking upwards (note the underside of the pedals and steering wheel seen through the floor hatch).

Below: The clutch thrust bearing required an extension piece, seen here in the lathe.

Below: The extension piece seen in the previous view, and the thrust bearing itself, to the left (and over which the extension piece fits).

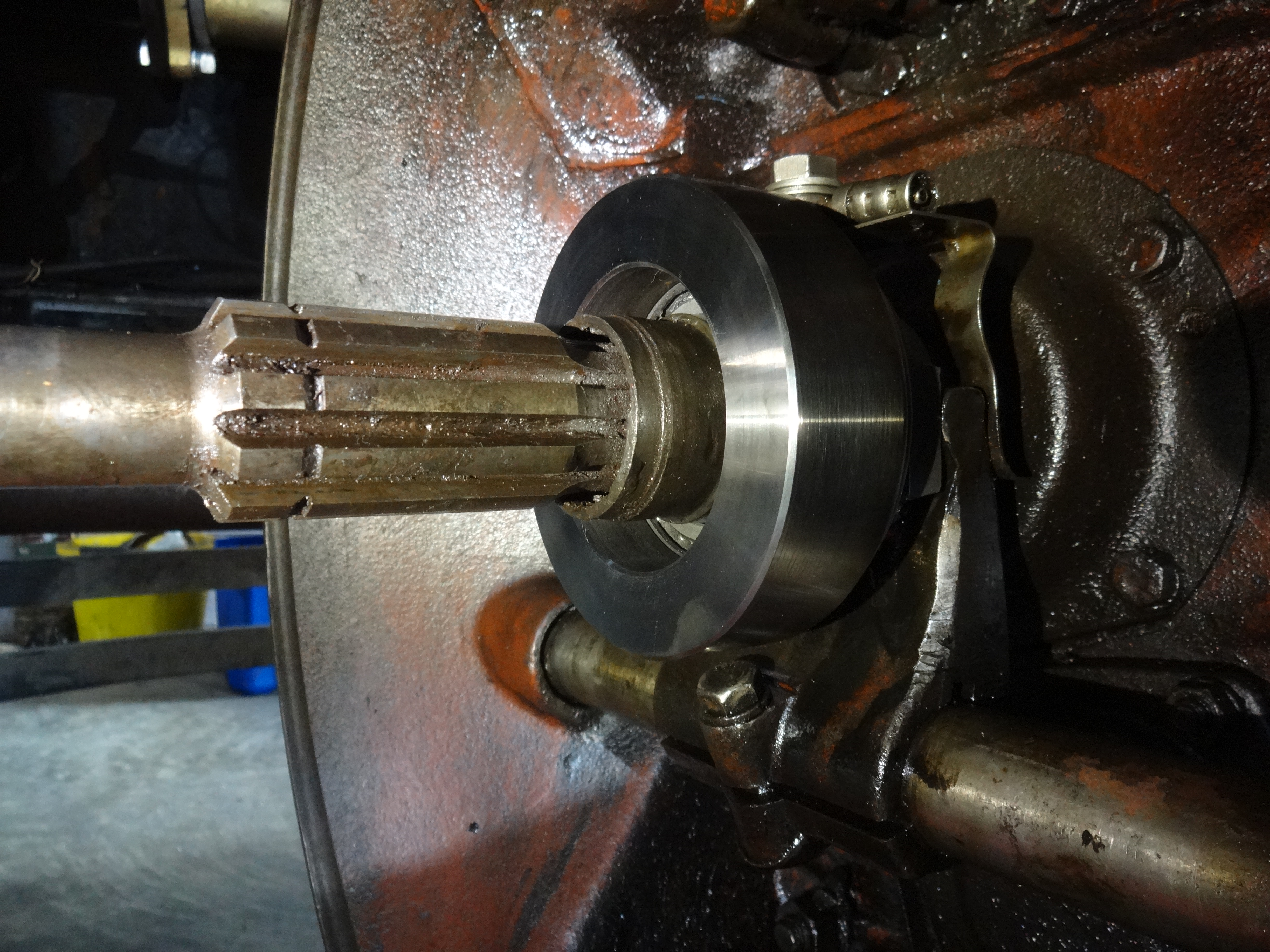

Below: This view perhaps makes the assembly clearer – with the extension piece over the thrust bearing, located over the spline of the input shaft. The clutch itself is with a contractor for modification (it having previously been overhauled there).

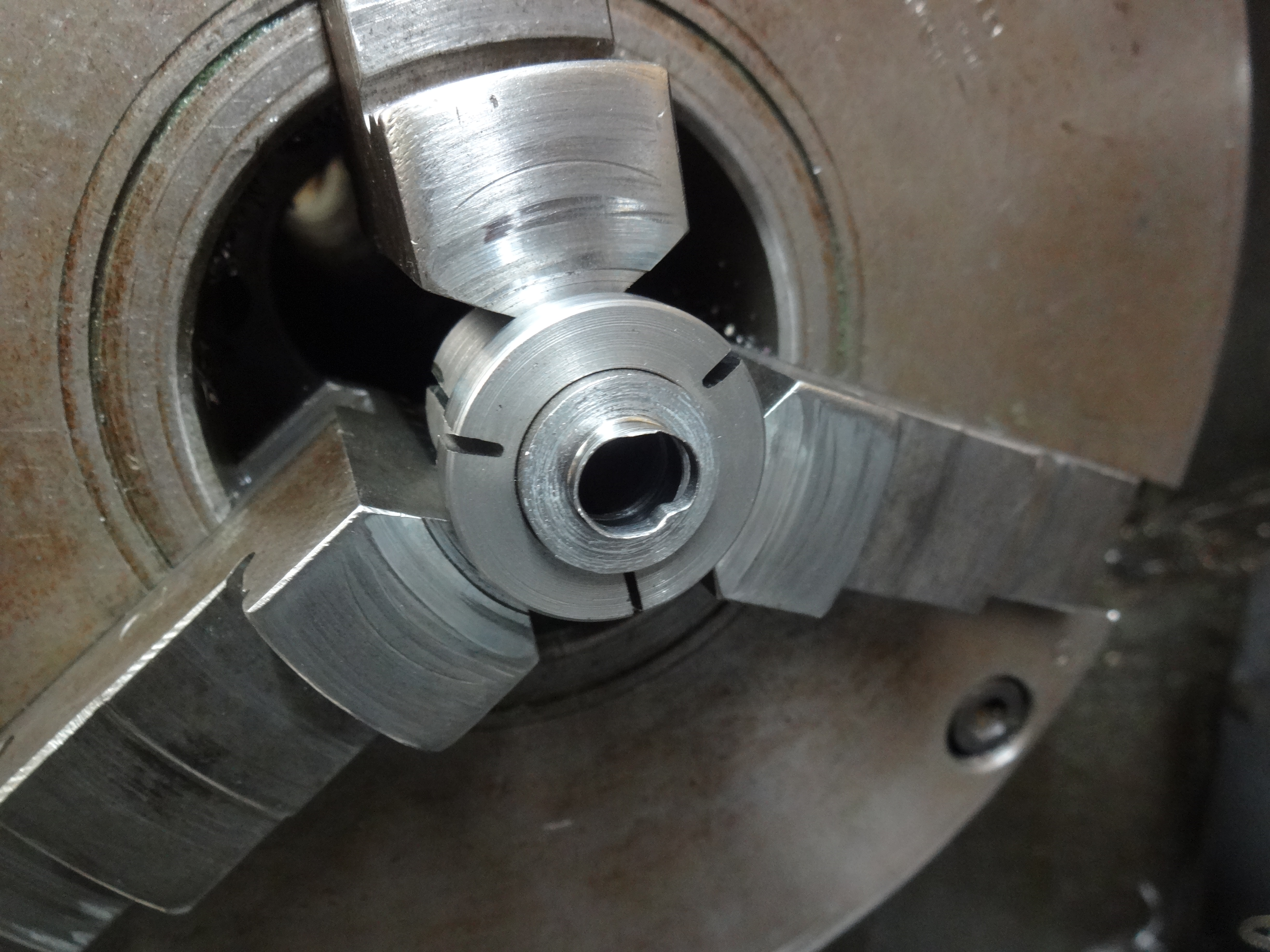

Below: The clutch assembly is also being modified, including spacers of identical dimensions. To hold the parent material from which these are made, Chris made a fixture for the lathe chuck, to act as a collet, which has a suitable back-stop to ensure that all of the spacers are faced to a consistent length.

Below: A small production run of spacers, available by the palm full!

Photos in this post from Matt Ellis, Chris Armstrong and myself.

Recent Comments