T&I News 5 2023…

This post is a bit of a roundup relating to various matters, as it’s been a few weeks since I had time to post on the blog. There is plenty going on, and as well as what is recorded below, I’ve been to the Heritage Railway Association conference, attended numerous meetings regarding our contribution to celebratory events in 2025 and also had a short holiday! We start with an update on Dunrobin, which forms part of our strategy for restoring operations to Rowley Station by 2025.

I noted with interest comments on Facebook regarding Beamish seemingly abandoning railway operations – as readers will know, nothing could be further from the truth and whilst we will see a late-start to the Waggonway operation due to the overrunning work on Puffing Billy, the Colliery lines are set to restart on the 1st April and we will be hosting a visiting locomotive there for a couple of months. As ever, the news on this site can be regarded as definitive and accurate!

Dunrobin

Two weeks ago I visited the Severn Valley Railway’s engineering works at Bridgnorth to view recent progress on Dunrobin and to discuss the next steps towards completing its extensive overhaul.

Below: We’ve seen the bogie in completed state before, but not with the final topcoats of mid-bronze green or lining applied.

Below:The driving (coupled) wheels are seen awaiting their axleboxes and trial fitting into the frames.

Below: The frames themselves are sat on stands, with the new cylinder block trial fitted into them.

Below: The new cylinder block has been pressure tested and has now been placed into the frames for final alignment and then bolting into place.

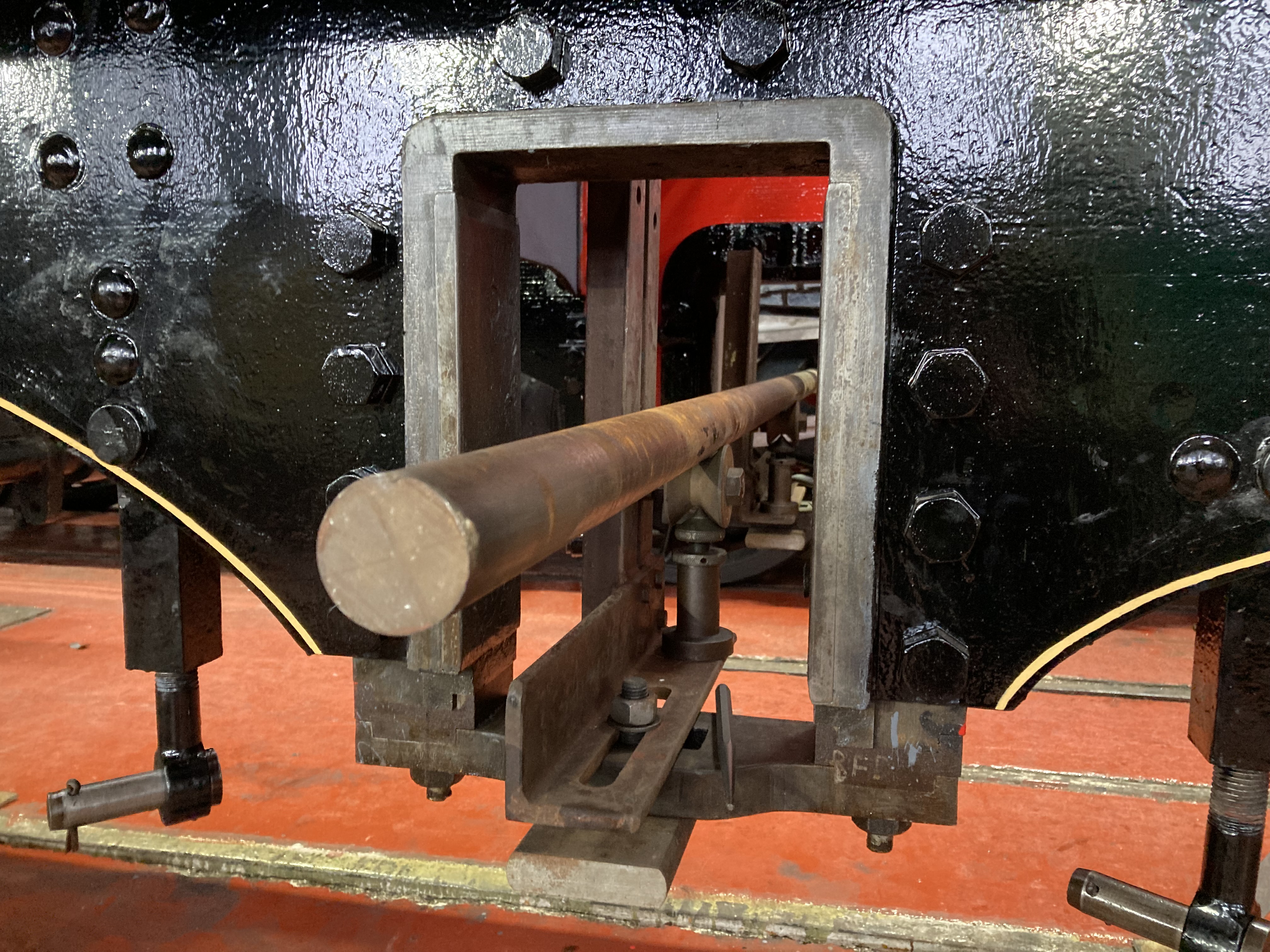

Below: To assist with aligning the cylinder block, an artificial axle has been placed in the aperture of the rear hornguides, to allow optical alignment to set the centreline from the axle centre to the cylinder bore centre. This uses a series of mirrors and a laser to refract the light and then set the final position accordingly.

Below: The splashers and sandboxes are seen in the foreground. These have been repaired/prepared for painting.

It is very encouraging to see progress on the overhaul, with the boiler also now being worked upon again. As ever, no timescale for completion is promised here, but it would be surprising if Dunrobin was not steamed early next year if the current rate of progress can be maintained.

Seaham Harbour Coal Drops

Below: In June 2010, the Seaham Harbour Coal drops were relocated from Rowley to a field between the Town and Pockerley. This was always intended to be a temporary move, and as the field that it resides in is needed in order to create an attenuation pond for the 1950s rainwater drainage, it has been relocated once again, this time to a site in the overflow car park. The plan is to fence it off and then add some interpretation until, at some point, it finds a new and permanent home (which could even be in Seaham if there were interest in this happening there). Here are a couple of views of the extraction and relocation underway.

Colliery Railway

Below: Following its annual boiler exam, Coffee Pot No.1 has been reassembled, tested and steamed for the insurance surveyor – followed by a very good clean, as depicted here. The flat waggon awaits the completed NER K class boiler to be delivered in the near future. There will be regular steam in the Colliery (Mon/Tues) from the 3rd April, and there will be several dates when the visiting Barclay, 1219, will be in use midweek as it is staying with us through to the 8th May.

Below: Some of the chaldron waggons received attention over the winter, with further applications of black bitumen paint made. The set has also gained a waggon, restoring a fifth vehicle to the demonstration train.

Tramway infrastructure

Below: Rail replacement continues on the tramway, with the high (outside) rail on the curve at Pillar Bend being replaced, and further changes to the means of securing the rails to the sleepers (replacing spikes with MOW clips) made.

Below: Some extensive repairs are underway on the museum’s roads over the next two weeks. These repair a number of degraded surfaces as well as complete works never quite done when the original top dressing of Tarmac was applied. The work entails planing off the surface to allow the new dressing to be laid flush, laying some new kerbs to retain the dressing where it meets a grass verge in places, and also surface a number of paths that have never had a top dressing on them. This work, totalling tens of thousands of pounds, will continue next winter, with footpaths and car parking areas on the list for attention.

Engineering

Below: 721’s frames have been inverted in order to ease access for trial fitting the axleboxes and wheelsets. In the foreground is one of Puffing Billy’s tender wheelsets, which has had attention to the journals after one became quite scored. The lubrication on Puffing Billy relies on holes through the timber frames, and over time we’ve seen these can ‘heal’ and starve the bearing surfaces of oil. A solution is to re-establish the passages, and also copper pipes can be inserted to line them. The risk of not doing so is damage such as this, and the downtime in repairs necessary. All that said, for such a basic form of lubrication, it has worked remarkably well over the years that PB has operated at Beamish.

Below: The re-tyred wheelsets have been placed into the hornways, sans axleboxes, and then spaced to enable measurements to be taken. These will allow for the variable dimensions between thrust faces, side to side, that will compensate for the rather variable nature of the frames alignment. They will allow a limited amount of sideplay, as clearance is very tight between the backs of the wheels and various fastenings on the frameplates themselves.

Below: This is the egg-end from Puffing Billy’s boiler, which is being modified so that it separates into two pieces. At present, to carry out work and inspections, the boiler has to be lifted slightly to release this component. This change will enable just the upper half of the egg-end to be released and removed, hugely improving access to the fittings that reside within it and also shortening down-time when any repairs are needed. The first step has been to remove the rivets to allow the ‘petals’ to separate. These will be retained and modified to form bolts that mean the appearance will not change, though the functionality will.

NER 559

Below: News from Darlington is that the K class’ boiler is complete and ready for blanking plates and hydraulic testing (due to take place imminently). This is a great step in the progress of the project. The photos show the vessel following NDT (non-destructive testing) and awaiting blanks and water. Once the tests are completed for the insurance company surveyor, the boiler will be painted prior to delivery to Beamish.

Hard to believe some (idiots) are accusing Beamish of ‘abandoning’ railway operations! They are obviously unaware of the aims, work involved and achievements at the Museum. Hope the Barclay ‘settles in’ at the Colliery & also hope to see it in action.

Thanks Michael. I’ll ask Matthew in ops for the dates that 1219 is running as we hope to be steaming it quite a bit during its stay with us – to make the most of the haulage and also the flurry of events that take us through to the Coronation Bank Holiday. Cheers, Paul

Will there be any visiting narrow gauge locos at this year’s gala?

Hi Matt – nothing booked in for April 1/2, but I’m working on potential guest locos for both the narrow gauge and standard gauge Colliery lines for the September event. Cheers, Paul

agreed michael,

luckily some of us who follow the blog know whats going on,

and the team is doing a great job with limited funding etc.

The bronze green now used on Dunrobin is much more attractive than the very bluish-green tone used in its earlier preserved condition. The painting of the wheels is a lovely job. So looking forward to seeing this unique locomotive complete.

Hi Euan

The colour applied latterly was certainly too-blue in tone. From the photos I’ve seen, the 1960s application was a much deeper green, and probably more closely matched what they found on it (it was stripped to bare metal when it was repainted in Vancouver). It was later re-sprayed and took on the shade most recently carried. Looking at photos closley, and trying to second-guess what the painters did in 1895, led to the selection of the mid-bronze green shade. The lining follows contemporary photos and certainly brightens up the livery! The yellow/straw replaces the gold applied in Canada, which was a paint rather than leaf.

Cheers

Paul

Hi Paul, With Puffin Billy not ready to run this week end (shame) when will pb be ready? also how long before the Steam Elephant will return to steam?

Thanks Gary

Hi Gary

Puffing Billy should be back by the end of April – we were held up at the start of the work by a supply issue, and have been catching up since then. In terms of Steam Elephant, the overhaul will start once Gateshead 10 is complete. There is only one machinist, his apprentice plus the steam technician available for this work at present, so as I’m sure you can imagine, timescales are always going to be longer than everyone might like, and the team under pressure to keep the running fleet going alongside overhaul work. We’d like to see Steam Elephant back for 2025, given the importance of that year in local railway history, but at present that is an objective rather than a guaranteed completion date.

Best wishes

Paul

Hi Paul,

I’ve noticed on the colliery railway you have started to put panlock keys in the chairs on the bullhead part of the railway in place of the old wooden keys, I any plans to do the whole area where bullhead rail is located please?

Many thanks

Cheers

Rob

Hi Paul, Thanks for your reply.

Just an idea as you wont need all the people at the waggon way with no trains running why not open the black shed so people can have a look inside (like what happens at the tram shed) people only at the door way just looking.

Regards Gary.