T&I News 4 2023…

This post marks a return to regular blog updates after some interruption in recent weeks – there has been a great-deal going on, which hasn’t left very much time to write about it! A few readers have been in touch about this, but rest assured that the blog is very much alive and active.

Steam Gala Visitor confirmed

It feels like a few years now since we’ve had a visiting standard gauge locomotive come to one of our events, so it is heartening to be able to announce that, for our first visitor in recent years, we will be hosting Andrew Barclay works no.1219, built in 1910 on our Colliery Railway. This loan is made courtesy of the Pontypool & Blaenavon Railway and Ryan Pope, and the locomotive will be in regular use from the 1st April through to the 8th May as part of an extended working visit to the museum. The locomotive was supplied new to Stewart & Lloyd Ltd’s Clydesdale Works near Motherwell.

Below: Two views of 1219 in steam at its home on the Pontypool & Blaenavon Railway in South Wales. (Photos courtesy of Alex Hinshelwood)

Below: Beamish has met this locomotive before – it was stored with Manning Wardle Newcastle and when we collected the latter, we had to first crane 1219 clear in order to create space to load our locomotive. Here are a couple of photos showing the restoration challenge ahead for owner Ryan Pope.

Winding Engine

Below: Work on the winding engine has largely concluded. Tests proved that it runs both more positively and with a greater sense of strength. This can be attributed to the steam available now being actively used (much of it was exhausted to atmosphere due to the worn valve-events) and enabling the engine to perform far closer to its original design expectations. The new drain valves have been fitted, and these are seen below, complete with a linkage to enable operation from ‘upstairs’ (the floor that visitors view the engine from).

Permanent Way

Below: The rail-welding in the Town area has become quite protracted, necessitating overnight working in order to ensure the tramway operation was not disturbed during last week’s busy half-term operation. David Moseley took these views of the contractors at work in the small hours. Work was completed overnight on Thursday/Friday. Not photographed, but also completed, is the re-railing of the outer side of Bog-Bend, with rails in place to carry out the same work at Pillar Bend shortly.

Below: With welds applied over several hours, they are then dressed by grinding, to restore the correct profile and gaps (as if it were new rail). Work is now complete on this section and whilst it has been a long-haul, with considerable amount of work being needed, it has restored the original rail section profile in this area and without having to lift the street surface in this very busy area.

Below: New stocks of flat-bottomed and grooved rail await installation at various locations on the tramway, during the next programme of PW renewal work. Work will shortly start on the long curved section known as Pillar Bend (named after a pillar that is no longer there!), between the Town and Foulrbridge.

West Riding 560

Below: The Perkins engine has been offered up to the Cub to see what might be needed in terms of modified engine mounts and changes to the chassis cross-members in order to incorporate the gearbox. This first step proved to be relatively successful, the fabricators now designing various brackets and modifications using CAD software, before committing to metal. Knowing that the engine now will fit, Russell has started the engine-overhaul process, which will see it fully rebuilt within a new working area adjacent to the bus and one which is dedicated solely to this project.

Kerr Stuart 721

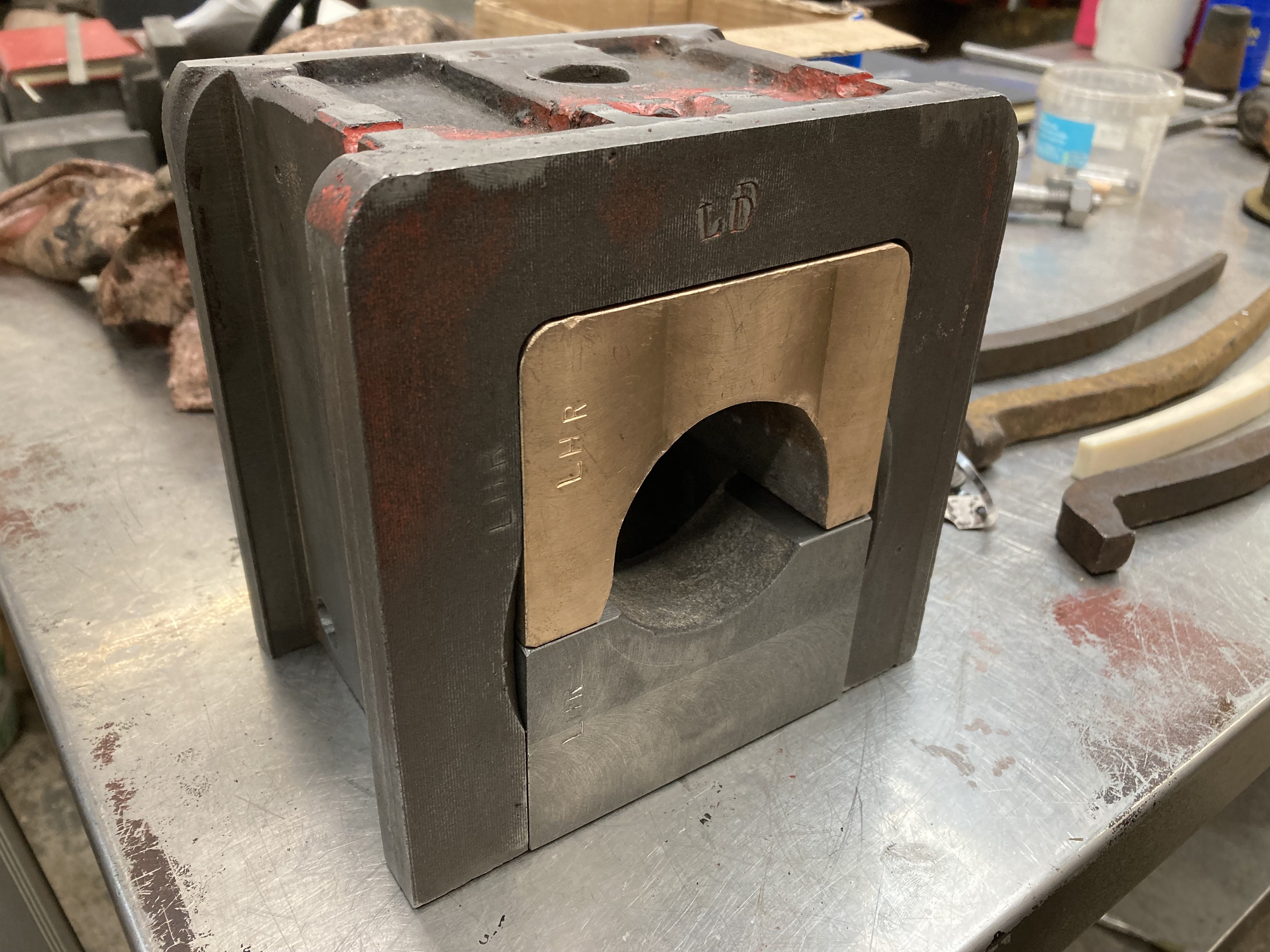

Below: Work is largely focussed on the axleboxes for 721 now. The hornguides are replacements, fitted when it was cosmetically overhauled for display at the Narrow Gauge Railway Museum in Tywyn, and have not been active on these frames before. With the overhaul of the wheelsets complete, and extensive restoration and replacement of components associated with these, the boxes are now coming together. Dave made patterns for new underkeeps, which have been fitted on all four boxes, new crowns (the bronze coloured shoes visible below) and one new axlebox (where the crown had worn away and the axle had been running in the cast iron of the axlebox itself).

Below: New keep and crown, within one of the original axleboxes, awaiting a session on the boring machine to open them up to accept the axle journals. The plan is to re-secure the hornguides with imperial bolts (temporary metric ones had been fitted), correctly fitted into the frames and castings, and invert the frames in order to make trying the axlebox and wheel assemblies within the frames easier (as the electric gantry crane hoist can be used for this).

Gateshead 10

Below: The brake blocks on 10 are held in place within the carrier assembly using curved keys. Three originals are seen here (the right hand three below) and show signs of wear, distortion and thinning. The one on the left is a 3D print, to test a drawing made for new keys, which will be laser cut to replace the full set needed on this tram.

Below: The keys fit into the aperture behind the brake blocks, visible here (with no key fitted). These anchor the blocks (the grey bits) to the carriers (painted in the brick-red colour). The blocks are entirely sacrificial and are regularly changed, whereas the rest of the brake assembly on the bogies has been extensively overhauled in order before it is eventually put back into service.

And finally…

Below The sign recovered from the now-closed Chester-le-Street Go North East bus depot has been installed on the northern end of the bus depot/workshop at Foulbridge. All that remains is to install the clock at the southern end, for which provision was made when the building was constructed.

Hard work, enginuety, money and organisation and understanding,

Is it possible to reverse history and go back to a less electronic age!.

Hi paul,

Thanks for that,

Any plans to get the Silksworth Sinking Engine which sits next to the siding at the colliery operational again please,

Many thanks

cheers

Rob

Hi Rob

No plans for that one. Drawings exist for the rest of the building that would have enclosed it and it was used a little in the 1970s using a portable steam sterilising boiler to run it. It’s very much on the ‘would be nice’ list but unless someone were to fund it specifically, then it isn’t on any current strategic plan for restoration to working order.

Best wishes

Paul

Thanks paul for your update,

When will the strategic plan be published please? as It will be interesting to see it

Hi Rob. It’s an internal document I’m afraid, but the gist of it is covered in the descriptions that I place on the blog and obviously which can be seen in the projects that we are working on for the next few years (Dunrobin, West Riding 560, trackwork, etc.). Cheers, Paul