T&I News 1 2024…

Welcome to 2024! I very much hope to increase the rate of posting this year, as it fell a little behind my own aspirations for the blog last year. I am also aware that the blog does need a bit of a refresh, and that some of the add-ons (such as the ability to subscribe to the blog) are either not working or aren’t working as well as they might. If there is anyone out there who might be able to assist with some of the admin in this regard, I’d love to hear from you! I’d also like to revisit the idea of transferring the stocklist into an Excel format in order to maintain a more up-to-date list on the site too. This was tried a few years ago, but for various reasons it didn’t proceed, so again, if anyone is able to assist with this, do make contact.

So, to 2024, and a busy start for the team and an extra-long post to cover it…

Lisbon 730

Below: On Monday 22nd January, Lisbon 730 made its second trip from Merseyside to Beamish, this time to take up a permanent position in our fleet. It travelled through he tail of Storm Isha, arriving in the afternoon, whereupon it was unloaded into the depot (initially to occupy a space in Road 1, pending commissioning). To enable this, Oporto 65 has been extracted and sheeted up, pending a move into another building on site (Gateshead 52 is also due to be relocated for storage until moved for eventual restoration). The team at MTPS had refitted the windows for us, and though one of the platform doors was damaged by the wind, the tram arrived safely and our initial thought is to quickly commission it for testing, and if satisfactory (which we have no reason to doubt that it will be), put it into service temporarily in the Lisbon livery. There is a lot of painting to do on rolling stock this year, so getting contractors lined up is key to when we can repaint 730. Gateshead 10 is to finish, Rotherham 220 has gone off site for work, and the North London Railway carriage at Rowley will be repainted into Highland Railway green later this year in readiness for Dunrobin’s arrival at the museum. On top of everything else that needs painting (a Model T Ton Truck, signs, window frames, doors etc. etc.).

Below: I’ve been quite surprised at the comments on social media regarding 730, and some quite negative observations about capacity. Whilst larger tramcars do carry more people (obviously!), as we now have much more of a balanced tram/bus operation, smaller vehicles that can board/disembark faster, are actually quite handy for keeping ‘orbit’ times down, especially at times of year where we run a double decker bus alongside one or two trams. This helps the headway (reducing it) and therefore gives the visitors waiting for transport both a shorter wait and, importantly, the perception that something won’t be long until it gets to their stop. Regarding livery, well, it’s going to run in Lisbon livery for now, but we will be repainting it into a local scheme, as this best meets the objectives of the Tramway’s curatorial purposes (alongside that of being a transport function). I detailed the reasons for choosing the early Darlington livery in the post introducing 730. That 730 had to find a new home, and we have 196 coming out of service soon, also marries very nicely.

I’d like to place on record again our thanks to the MTPS for offering 730 to us when they had to find it a new home, and for making the arrangements for it to move to the museum – this was a generous and much appreciated gesture and I hope that their members can enjoy seeing 730 at work, at Beamish.

B-Bus woes

Below: At Christmas, the B-Type replica had an in-service failure whilst being turned (empty) at the end of one the day. The exertion on the steering caused the sector shaft peg (that imparts the rotary motion of the steering column through to the steering rack) to sheer, rendering it impossible to steer. The recovery (the following morning) entailed suspending the front end of the bus then slowly towing it back to the workshops (noting its brakes were still operational).

Below: The sheered sector quadrant peg. Within minutes of arriving back into the workshop, the team (with help from across the specialities) stripped the bus of its steering box and removed the peg. The bus had been recovered at 8am and was back on the pit for this by 9am. A new peg was manufactured, fitted, and the bus was re-inspected before re-entering service before lunchtime! It is these incidental breakdowns that would once have floored operations for a period of time, but now, thanks to the skills of the team and the development of the facilities, can be considered as annoyances rather than more disruptive.

Below: The B-Type is receiving attention to the body panels at the moment. The body is steel framed, and corrosion is making its presence known. Here Matt is removing some of the beading in order to access the panel below. This bus works incredibly hard for us and is a very robust vehicle. We do have to consider, though, that the replicas are reaching an age where an operator would consider them long-since life-expired, and so they do require more and more work to keep them safe and fit for service. The Colliery service is a particualrly challenging route as it can only be operated by the two replicas (for curatorial and height reasons), placing a lot of pressure on them. A solution to this is often pondered, but we haven’t reached a firm conclusion yet!

Below: The same bus is also having a brake overhaul, with all of the cylinders away for re-lining, so whilst it is off the road for these to be done, the opportunity has been taken to remove the staircase – this will have new treads fitted, but first it is being sent for shot-blasting and powder-coating.

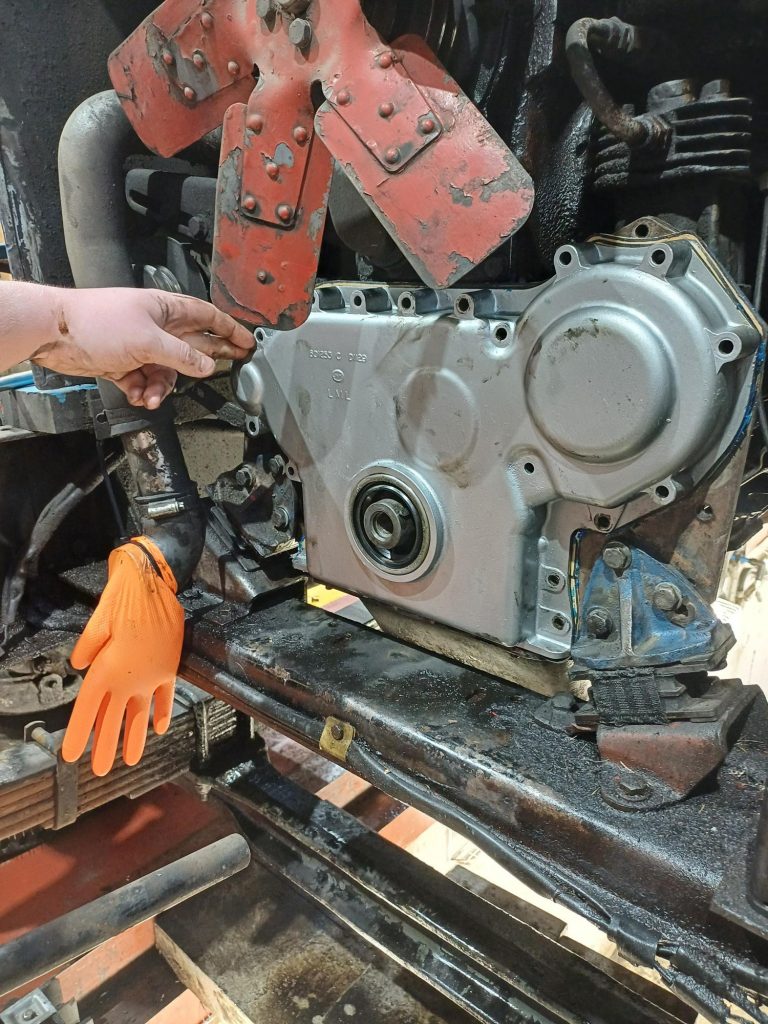

Below: Another job that has been done on it, whilst it has been available to the workshop staff, is fitting a new timing case oil seal, with some machining work being undertaken to make better mating surfaces for the seals, hopefully curing a persistant leak in this area.

Gateshead 10

Below: Work on Gateshead 10’s repaint has now turned to the interior, with the inside of the dash panels and controller cases being attended to at the moment. The bench seats are receiving a gentle flatting, and will then be stained/varnished – but we’re keen to retain the glorious patina inside the saloon of the tram, as it is something that really cannot be recreated other than through age and use.

Newcastle 114

Below: In the first of several updates from Chris in the Fabrication shop, here are Newcastle 114’s brake ratchets (operated by the driver’s foot, and used to keep the brake tension on when applying the handbrake) being restored to profile. Chris used Rockwell hard surfacing electrodes when building the pawls back to profile, to ensure longevity of these high-wear components. These are what can be heard ‘clicking’ when drivers apply the handbrake during operation/parking.

Road Vehicles

Below: The previously seen gritter is now being reassembled, the chassis having been shot-blasted and then powder-coated. We went for orange, so as to be able to tell the two apart easily! It has also been suggested that a public competition to suggest names for both might be held… Gritty McGritface has already been suggested. I quite liked ‘Scott & Charlene’ too!

Below: On Crosville 716, a routine brake inspection showed an imbalance between left and right front brakes, that further investigation showed to be partly air in the system and partly movement of the lower brake shoe anchor (which was shimmed). 716 is racking up quite a mileage – certainly for a bus of its age. We are all keen to get on with West Riding 560 to supplement the wheelchair accessible fleet.

Below: Rotherham 220 is currently visiting our contractor for an external repaint. A lot of preparatory work was carried out at Beamish, so it is hoped that this will be a relatively quick job, as we’d like to have the bus back in time for service at Easter.

Below: During routine inspection, some cracks were noticed on the Daimler D-Type’s engine cross-member mounts. These brackets sit within the chassis rail and provide a flat surface for the cross member, which more or less obscures them for a visual inspection. With the issue caught, Chris was asked to look at them and what repairs might be possible. His examination revealed further cracking, appearing to emanate from the stud-welded captive nuts (the cracking possibly emanating from the original resistance welding of these components). Here is one of the brackets, showing the cracks before further exploration.

Below: Here are both brackets, after the welds were identified and ground out to allow them to be repaired.

Below: Chris added stiffening plates to the rear (inside) of these brackets – as seen here prior to being welded into place and showing the clearances of the nuts that provide anchor points for the cross member to be bolted to the brackets (it is easier to picture how these slot into the U section of the chassis rail here, to create a box).

Below: Following repair and painting, the two brackets are seen ready for fitting back onto the bus. A further example of even the replica vehicles beginning to show their age now (having had life spans far in excess of those usually experienced by the vehicles upon which the replicas are based, of course!).

Below: Chris then turned his attention to the Austin 10 car, that has been on the back-burner for some time now, but progresses as and when the opportunity allows. With the boot pan quite badly rotten, as seen here, a new boot pan was required.

Below: The new pan shown fitted in place prior to securing to the shell.

Below: The pan secured into place.

Below, Dan, Chris’ colleague in the Fabrication Shop, has been manufacturing vehicle components too – the first shown being half of the rear tailgate from the ‘modern’ Nissan Navara the the museum operates as a support vehicle. The limitations of the forming tools meant that it was made in two halves. These were then welded in to replace the ‘iron oxide’ section (rust!) – part of a whole programme of work to improve the Nissan and also ready it for MoT.

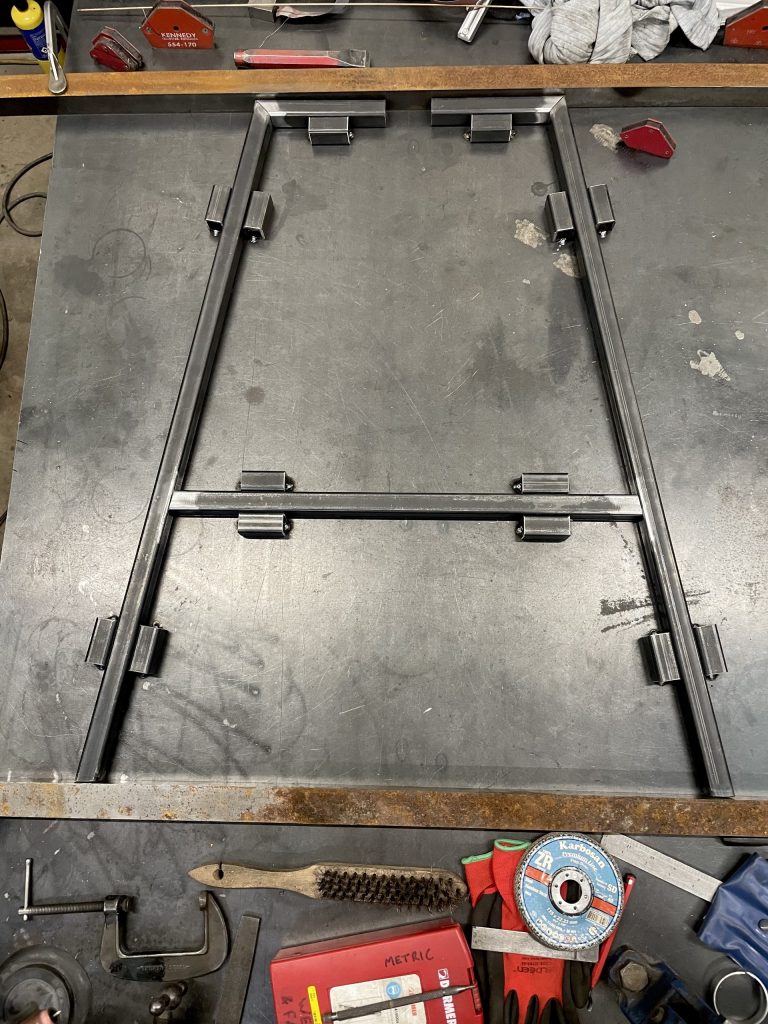

Below: It’s not all transport! Here are some record racks that are being manufactured for the 1950s electrical shop, which include a steel leg frame (shown separately in the second photo). The timber sections have been manufactured in the buildings joinery across the road from the Fabrication shop here by Shaun and Dan.

Steam Maintenance

Below: The annual boiler inspections usually entail some repairs too, and here are the mudhole doors from Coffee Pot No.1 on Chris’ bench. These doors are located in the boiler shell to allow the cleaning of the boiler internally (washouts) and also internal inspection. They sit inside the boiler, being pushed outwards (and tight) by boiler pressure, and are secured by a bridge over the integral thread. A joint is placed around the lip/seat of the door, to assist in creating a steam/water-tight seal. These items are subject to corrosion, as they are located internally, and so receive attention on a fairly frequent basis in order to ensure that there is sufficient lip upon which to locate the gasket and to land the door securely against the inside of the boiler shell. Here are the worn doors before attention but after cleaning.

Below: Here is a a repaired door, with the lip restored by welding, and then dressed back to a smooth finish. Because these repairs can be made a number of times in the life of a door, Chris made a radius gauge (based on the boiler shell size, rather than worn door, and allowing for the compression of the joint thickness) in order to maintain the form of the seat both this time, and for future repairs.

Below: All of Coffee Pot’s refurbished doors, ready for inspection and then fitting when it is recommissioned this spring.

Permanent Way

Below: The team have been replacing the sleepers on the Town-West curve, leading towards Foulbridge on the Tramway. This work was done with minimal disruption to the rails/bonding/formation, by replacing the sleepers one by one (made easier to extract and handle by the JCB). The check rail has to be removed to allow access to the spikes that secure the low (inner) rail. We have previously intonated a move towards using recycled plastic sleepers for all renewal work, but weren’t able to allocate the budget in time to enable us to order these for this work, so have used hardwoods instead (as we could purchase these, left over from a commercial job elsewhere, at a rate we could pounce on them for). The plastics seen below will be reused elsewhere.

Below: The running rails and track bonding (that provides the earth return for the traction current that the tram operates on) were left intact, though the high rails have been secured with clips and screws, in place of spikes – giving a much more secure fastening. After alignment and packing work, the check-rail will be reinstalled, and the section handed back for operation. All of the sleepers have been replaced on this section, which was re-railed several years ago.

Below: The check rail is back in place, and work draws to a close… The next job is likely going to be replacement of the grooved rail on the outer-circle lines at the eastern end of the Town.

Photos in this post by Paul Jarman, Russell Walker, Neil Sullivan, Chris Armstrong, David Moseley and Ben Wilson

Great to see beamish using Autosmart products :),

I use them and they are brilliant, biobrisk is great for removing nicotine smells

cheers

Rob

Love reading the blog it’s very interesting to see what goes on behind the scenes at beamish to make it a magical experience for the visitors I also learned alot from reading this aswell keep up the great work.

i go to beamish by bus alsa no seats at or neat bus stop at main entrance any chance?

Hi paul

Could you do a history on the colliery setup at beamish please? everything about it pls, as it would be good to read inc buildings etc,

Also I’ve seen on a vid that the cage in the shaft moves using a electric motor (i know the winding ropes are continuous winding) is that still the case pls?

Many thanks

cheers

Rob

Hi Rob

The history request might take a while to fulfill, as I’m committed to a couple of books this year and into next, and so have struggled to keep the blog up-to-date! But I’ll keep it in mind.

Re the cages, yes, there was once a function to move them up and down about 20 feet (not attached to the winding rope), in order to demonstrate the process in the heapstead. The mechanism for this is below ground level and is largely flooded, and would be very hard to service in this day and age. I’ve never seen them work, so it must be 25 years or so, maybe more, since they did.

Best wishes

Paul

Hi paul

Many thanks for your reply, really appreciated

looking forward to seeing the work to rowley this year

Cheers

Rob

seats at bus stop any chance??