Transport & Engineering Diary 2026 January Part 2

With plenty of content by mid-January, there will be enough material to have three posts this month, covering something of the variety of workshop and operational news that has occurred.

Snow days (they’re snow fun…)

Luke Griffiths, one of Beamish’s Tramway Supervisors writes:

We are now very much in the midst of winter, and have already had our first ‘snow days’ of the year.

Snow and ice, when it comes, is a particular challenge for an open-air site like Beamish. The first difficulty is usually getting here in the first place, with hills having to be navigated no-matter which direction you come from. Then there is the duty of care we have towards our staff and visitors. This usually means a great deal of snow shovelling and salt-spreading before we can even think about opening.

Modern equipment helps, especially the Landrover Defender and towed spreader, alongside the Kubota tractor for ploughing and gritting footpaths. The museum also has a contract arrangement to grit the roads around the museum. On the tramway however, we don’t have the luxury of modern equipment. When the temperature is hovering around 0, there is always the anxiety that old vehicles might be a bit difficult to get going. The worry is compounded by the fact that visitors have an increased expectation that a frequent transport service will run in bad weather, to save any prolonged queuing out in the elements.

All of this means that the tram and bus depots are usually a hive of activity when things turn cold, after a fortifying cup of tea of course. The first task is usually to start the buses in use that day. Some of the buses are better than others when it comes to cold starting. The cub takes a bit of coaxing, and some of the visiting vehicles have been known to need a jump pack occasionally.

Below: Weardale 909 and Scout 18 are seen quietly burbling away to themselves after start-up on a snowy morning back in November. If only you could attach sound to pictures here! These Leyland’s have plenty of fans within the department, and their sure-starting whenever it gets cold is another reason to love them. Weardale 909 stands by the jet-wash, which is incredibly useful for cleaning the grime (and salt) which accumulates at this time of year. We also try to mop interior floors, although after a few laps you might not be able to tell!

Below: The B Bus warming through outside the depot. A chilly day lies ahead for the crew, despite the protection afforded by the windscreen. This year we have been very fortunate to train a number of new bus drivers, and have welcomed a couple of new bus-driving volunteers as well. This gives us more flexibility on days like these to rotate crews and offer extended breaks for welfare reasons. We have also upgraded our tea-boiler, and have a ready stock of Bovril!

Below: Sheffield 264 considers poking its nose outside the depot doors on a frosty morning. The trams come with a different set of challenges when things turn fresh. We don’t have to worry about cold-starting, but we do have to consider the infrastructure. There are usually points to unfreeze, railheads to clear (especially in the depot yard) and ice to remove from the overheads. We always run a tram around the route without passengers in order to ensure everything is clear for operation before we even consider entering service.

Below: Oporto196 is a popular choice for route proving. Loaded with extra sand and a few willing souls with shovels and bars, it is waiting here to make its way carefully around the circuit before opening-time. Sometimes multiple runs are required. Pockerley Bank is usually traversed twice, to ensure that both of the overhead wires are clear of ice and that railhead conditions allow for safe operation in each direction.

Below: A real team effort. Last Sunday a gang onboard the B bus accompanied Sunderland 16 around the circuit, shovelling, sweeping and clearing as they went. This is a great example of tram and bus working in perfect harmony. The gulf between tram and bus people isn’t as wide as the mess room banter would have you believe!

Below: Due to the conditions, staff are sometimes asked to park in the main visitor car park. This can mean a long walk after work, but over the last few snow days we have run a special end-of-day works bus to take staff back to the main entrance. Here Scout 18 stands on the Town Street on an evening which was decidedly warmer than the morning.

All of this is usually quite entertaining and a good team building exercise. While we like to think we have it tough, the reality of the situation is our recent bad weather doesn’t really compare to some of the cold-snaps experienced by our brother and sister transport operators in the past.

An impulse buy…

Below: At a recent sale of narrow gauge equipment located at the Tanfield Railway, I saw this point lever, and for a small sum, was able to purchase it for future use at Beamish. It is of the type with an articulated lever, which makes the movement of the weight very positive and also highly unlikely to move when trains are passing over the associated pointwork. It was collected using the Leyland Cub tipper and moved to the machine shop where Sam carried out its overhaul.

Below: The actuating rod from the lever was bent, so the press was employed to straighten it after the lever was dismantled.

Below: All of the holes were made circular again, and new pins made to suit.

Below: The clevis was treated to heat to straighten it and the holes welded up to allow re-drilling centrally (and as circles again).

Below: The overhauled lever unit after painting and assembly. It will be stored pending purchase of further narrow gauge turnouts (I’d love to hear from anyone with spare ex Eastriggs 35M left or right turnouts that they may have spare…).

Tramway

Below: The replacement rails and sleepers have now been installed at Foulbridge, and the bonding connections (to ensure electrical continuity for the earth route via the rails) have been fitted. Some final alignment and packing work remains to be completed, after which the area will be handed over to the contractor who will fill the space with hardcore and Tarmac.

Below: As part of the widening scheme at Foulbridge, effectively creating a roundabout for vehicles entering/exiting the Colliery route, one of the traction poles in the depot yard is being relocated. The replacement pole has now been installed (shown here) and the OLE equipment will be transferred across to it and the old pole removed as part of the process. The ground surface will then be made-good, and the area below where the Transit is standing and beyond (to the left) will also be given a top coat of Tarmac. This means buses will be able to go right-way-round on the roundabout, giving them a better alignment into the bus/tram stop as well as obviating the need to mount the pavement to complete their turn.

Below: A bi-product of the work at Foulbridge is the operation of the Tramway on a horse-shoe, bringing into operation the use of the crossover in High Street and reversal of trams there – much to the interest of the visitors. Here Sunderland 16 has reversed after passengers have alighted at the Redman Park stop, and is approaching the Bank Stop to pick up waiting passengers, whilst Scout 18 is on the inner-circle bus service (which has been unencumbered by the work taking place at Foulbridge).

Below: During the closed days Monday – Thursday, sleeper replacement is underway between Town East and Pockerley, on what is an exposed section of line and one which has received a lot of attention in recent years, including installation of plastic sleepers at regular intervals too.

Below: Over the next few weeks, major contract works are to be carried out on the trackwork in the Town, principally building back wear in the rails outside the Bank. After this, the Overhead Line Equipment (OLE) is due to receive the attention of a contractor to continue the programme of replacing span wires and insulators, amongst other jobs.

Below: Alongside the Tram and Bus Depot, extensive clearance is being undertaken of the trees and undergrowth that has grown there over the last few decades. The new traction pole can be seen just behind the chipper, and components are in-hand for this to enable transfer of OLE components in the next month or so. There is also some improvement to make to the surface beyond the turnout in this view, as part of the bus/vehicle turning circle improvements.

Lisbon 730

Below: Mention was made of the proposal to fit Oporto headlights to 730 – John Marshall has very kindly manufactured some pattresses for these to be mounted on.

Below: The ex Oporto headlamp surrounds are shown in undercoat, pending fitting to 730.

Below: A few more photos showing progress later in the month, with undercoat flatted back, lamps surrounds fitted and ready for installation of the lamps themselves. No painting can really take place due to the cold temperatures we are experiencing at present. The Oporto headlamp is, to me at least, a great improvement over the commercial vehicle type (authentically) previously fitted and is a small action in helping to blend the tram into the Edwardian surroundings at the museum.

Below: By the end of the month, some newly-received paint, matched to that on Newcastle 114, was tested on 730… Note that the lamp and reflector has now been installed within the headlamp unit. A more aesthetically pleasing bulb will replace this one.

Below: Also in the paintshop are various bits of Gateshead 10, including the destination boxes.

Wheelchair Accessible Vehicle J2007

Below: This vehicle has been living on borrowed time for several years. Work was planned to be carried out on the roof just as we entered the first lockdown in 2020, and since then, opportunity or resource has prevented the roof leaks being revisited. However, they have now become bad enough that it was decided to investigate then remedy this situation.

As can be seen, the roof has been patched with sealing tape previously, but this has begun to break apart and let water into the structure.

Below: Internally, when the wooden panels were removed, the damage caused by water ingress was clear to see. The roof panels themselves are aluminium and are in good condition – it is the joints that have been the Achilles Heel for the bus.

Below: A close-up of the degraded roof tape, showing how much it has perished.

Below: Whilst it was hoped the roof could be patched again and the saloon ceiling re-skinned, this would be a great deal of work to not really solve the problem. As some sections were explored, it was also revealed that the fairly slender steel box section roof structure had corroded, and so the decision was taken to remove the roof completely.

Below: With the panels removed for cleaning up and re-use, the exposed structure can clearly be seen here. This is being cleaned and treated, repaired as necessary and will then be in a better condition to receive the panels back.

Below: Elsewhere on the bus, the effect of road salt and water can clearly be seen, which will necessitate renewal of some of the components below the body.

Below: The Iveco chassis is in good condition, as seen here, but the body structure does require renewal in places. The body was always quite ‘flexible’ and the intensive usage the bus received for many years has resulted in this situation. With Crosville 716 being anticipated for several years of J2007’s life, it was hard to justify the level of work needed on a cost and interruption to use basis, but we find ourselves in a situation that requires at least two Wheelchair Accessible Vehicles due to demand (victims of their own success!). The United Bristol will probably provide us with our next genuine WAV vehicle, but is some years from being restored, so J2007 will receive yet more surgery to try and extend its life, probably into the early 2030s. After that, we will probably find that the chassis/engine is beyond economic resuscitation and so the service will become one entirely operated by vintage buses.

Samson

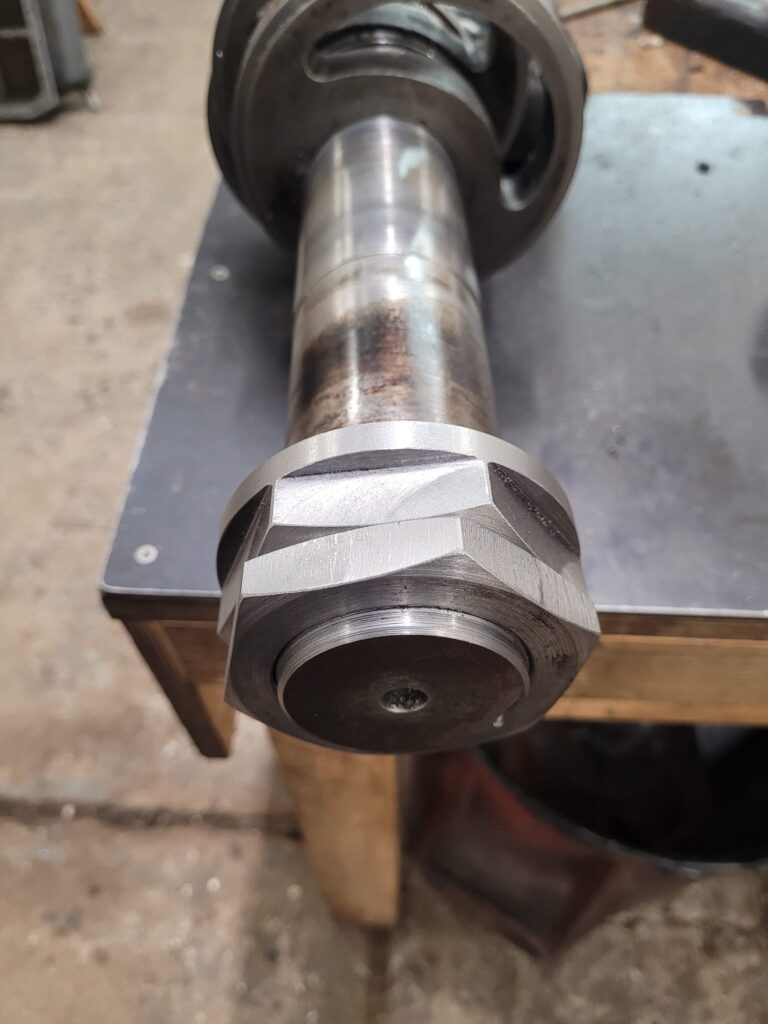

Below: The crankshaft for Samson has been having the flywheel end modified in order for it to take a locking nut to secure it to the crankshaft. Here is the thread for the nut being cut.

Below: A start on the nut – this will be made hexagonal, then split to create the pair of nuts that will act to lock the flywheel in place.

Below: Milling the flats to create the hexagonal shape of the nuts.

Below: With the piece split, the two components can be seen on the end of the crankshaft – the inner piece having a full-circle profile to act against the flywheel casting.

Below: Meanwhile, in Wales, the firebox door surround has been refitted and grate installed. The firebars sit on a taper at the back, and each was checked to ensure free and easy movement and no binding, grinding the ends where necessary. Hopefully this will limit the tendency for the bars to arch. The backhead, firehole door, surround and angle ring to the boiler barrel have all been treated to a coat of high temptation black paint. The gauge glasses were also refitted after this photograph was taken.

Below: This view shows the new position of the injector, with modified pipework. The hideous plastic-coated red valve handle will be hidden and have an extension which will come through the cover plate, with a nice bronze handle on it! Injector overflow pipe and blowdown valve extension handle still to make.

Below: One of the volunteers has given all the cladding sheets a further clean up then prepped and painted the inside surfaces ready for refitting. They’ve also taken the oil drip trays and a small section of cladding (which needs totally repainting) away to build up coats on them. Once the cladding is refitted, they will touch up the otherwise good paintwork.

Below: The front firebar and firebrick carrier. The groove that the front of the fire bars sit (left in this view) and hook into always filled with ash, meaning the bars couldn’t move when they expanded. This is one of the reasons the bars arched upwards over time. Some slots have been cut in the carrier in an attempt to allow the fine ash to drop through.

Photos in this post by Matt Bedard, Phil Doran, Matt Ellis, Luke Griffiths, Paul Jarman, Gary Kester, Phil Smith and Sam Telfer

Recent Comments