T&I News 1 2019

Welcome to the blog in 2019. Here we have the annual summary of tramcar mileages as well as an update of what is going on in and around the workshops.

Regular readers will be familiar with our annual reports on the tramcar mileages. This season the mileage total is slightly down on previous years. Early in the year there were various trams having routine maintenance work. Unfortunately there were a couple of failures which cost us days out of service too. Daimler Bus 220 has seen increased use covering for this lack of availability.

Sheffield 264 has been the mainstay of the fleet this season, completing 7825 miles, the highest in the fleet. The tram suffered a failure to a motor in late March, which cost us a week out of service when we could least afford it just before the Great North Steam Fair. With a great effort by Chris and Brian it re-entered service for the Saturday of the event and has been trouble free since. Once 16 entered service the burden on 264 was reduced.

Below: Here we see 264 with life trays and steps removed, along with motors and brake gear disconnected in preparation for lifting the tram off its truck next week. The wheel sets require re-profiling along with a motor overhaul. It is intended for this work to be done and the tram to be back in service for the summer season.

Newcastle 114 has been as reliable as ever, undertaking 5600 miles in service. It had its controllers overhauled early in the year and this has aided its reliability. The open top cars see use across all seasons now due to the service requirements. This isn’t a problem and we find that passengers still fill the open seats first in all but the worst weather conditions.

Oporto 196 has completed 4700 miles. The car was troubled early in the year with compressor and then compressor governor faults. Frustratingly these took some time to get to the bottom of and cost some days out of service. As usual it has been the car of choice for crew training and drive a tram experiences.

Blackpool 31 returned to service in late June and has completed 4150 miles since. As predicted it was immediately popular with crews and visitors alike. Importantly it brought the fleet strength up to four cars just when we needed it most. Instant relief all round then.

Sunderland 16 was lifted almost as soon as 31 was back in service. Between January and June it had some work done on the controllers prior to it being lifted. With the wheelsets re-profiled and the brake gear overhauled, it was reassembled and re-entered service in October in time for the evening events and Winter season. This for the, first time in a couple of years, brought the fleet strength up to five. As with 31 a great relief. Sunderland 16 completed 2225 miles and is likely to be the high mileage car of 2019.

Looking forward to this year. We start the year with 31, 16, 114 and 196 available for service, each will have minor works planned prior to the main season to ensure reliability for the rest of the season. 264 is having motor and wheel set work as mentioned, we should then see five cars available for most of the season once this is complete.

Gateshead 10 has made some progress with controllers and the compressor receiving attention. Work will progress this year, keep an eye out for updates in the coming months.

Below: The vehicle workshop is a hive of activity, with the Landrover and Fordson Tractor in view.

The Fordson tractor came in after an electrical fault caused a failure. Whilst in to be re-wired, the opportunity was taken to correct significant kingpin wear. The housings have been bored, new bushes and new kingpins fitted. It is awaiting delivery of wheel bearings prior to re-entering service.

The Series 2a Landrover is in for inspection prior to MOT. Small jobs have been completed and it will go for MOT next week.

In the machine shop the Centre Engine is making good progress. The crankshaft is back from having the journals ground so now progress can be made on fitting it.

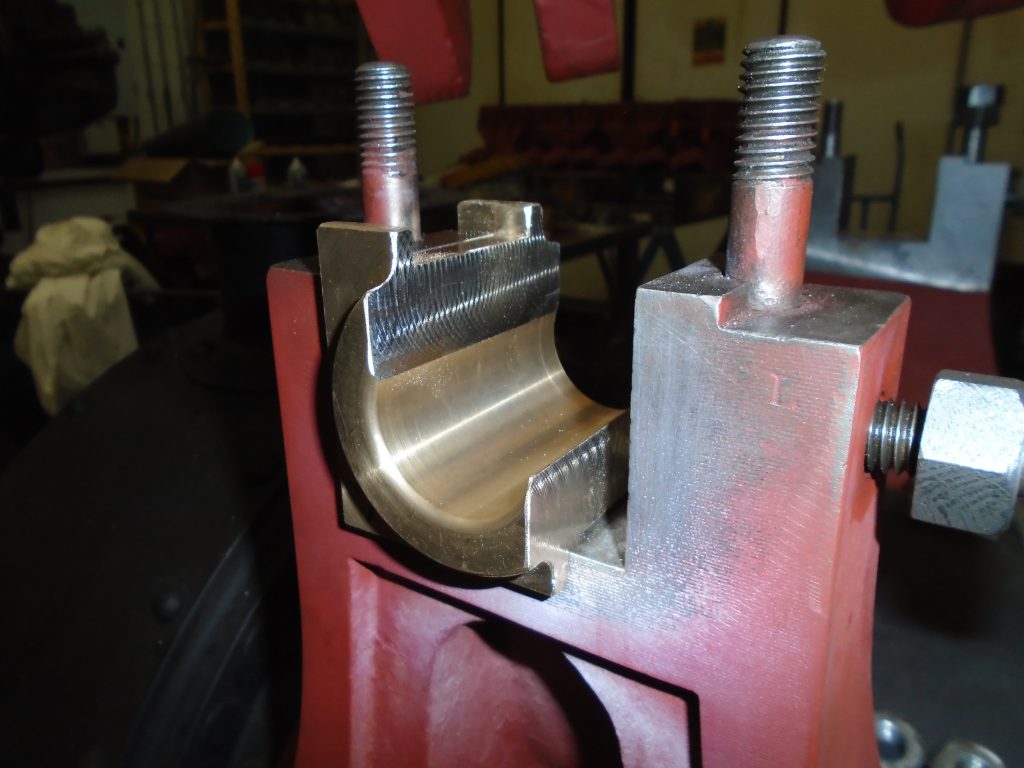

Below: Here we see Don machining the new crank shaft bearings.

Below: Later in the week the bearings are fitted into the pedestals and then the crank is temporarily fitted. The fit of the bearings is being checked with engineers blue.

Below: The RHEC completed the rebuild of this trailer just before Christmas, which incorporates iron work surplus to requirements from the drop side body of the Model T ton truck.

Below: The Pew Coach is now fitted to its chassis and just awaits the manufacture and fitting of draw gear to complete.

Below: There has been some progress on the Ffestiniog granite wagons (Nos 338 & 443). Here we see the first of the 4 wheelsets cleaned and primed.

Below: All eight axle boxes and under keeps have been cleaned, old oil brunt out and primed. The key tags are a handy way of keeping track of what goes where.

Below: These two wagons are braked, as is 825 (yet to be started). The brake gear on them all ranges from totally missing to present but totally worn out and damaged. Whilst we are doing these wagons we are making the set of brake gear for 825 too. In this view there is a variety or refurbished or new components which will go into these sets.

Preparations for the Great North Steam Fair continue and we hope to be able to make some announcements of exhibits in the coming weeks. As usual this time of year is busy for us whilst we gear up for the new season, which should provide plenty of material for blog posts. I will endeavour to improve my own photography skills so that images are clearer!

Below: Over the festive period I made an off site visit to see this. I will leave readers puzzling for now but hopefully all will be revealed soon.

that last photo… maybe a fair ground ride, a carousel? same colours as Neilson 4444 but not sure the anyone, will buy that sadly

Paul, was the trailer built by the TYE trailer Co by any chance?

All very interesting as usual, was wondering what is happening with the Trolley Bus route- not heard anything about it in a while.