T&I News 20 2022…

This week we are mainly looking at the heavy overhaul of Gateshead 10, and some of the progress made in the last couple of weeks.

Gateshead 10

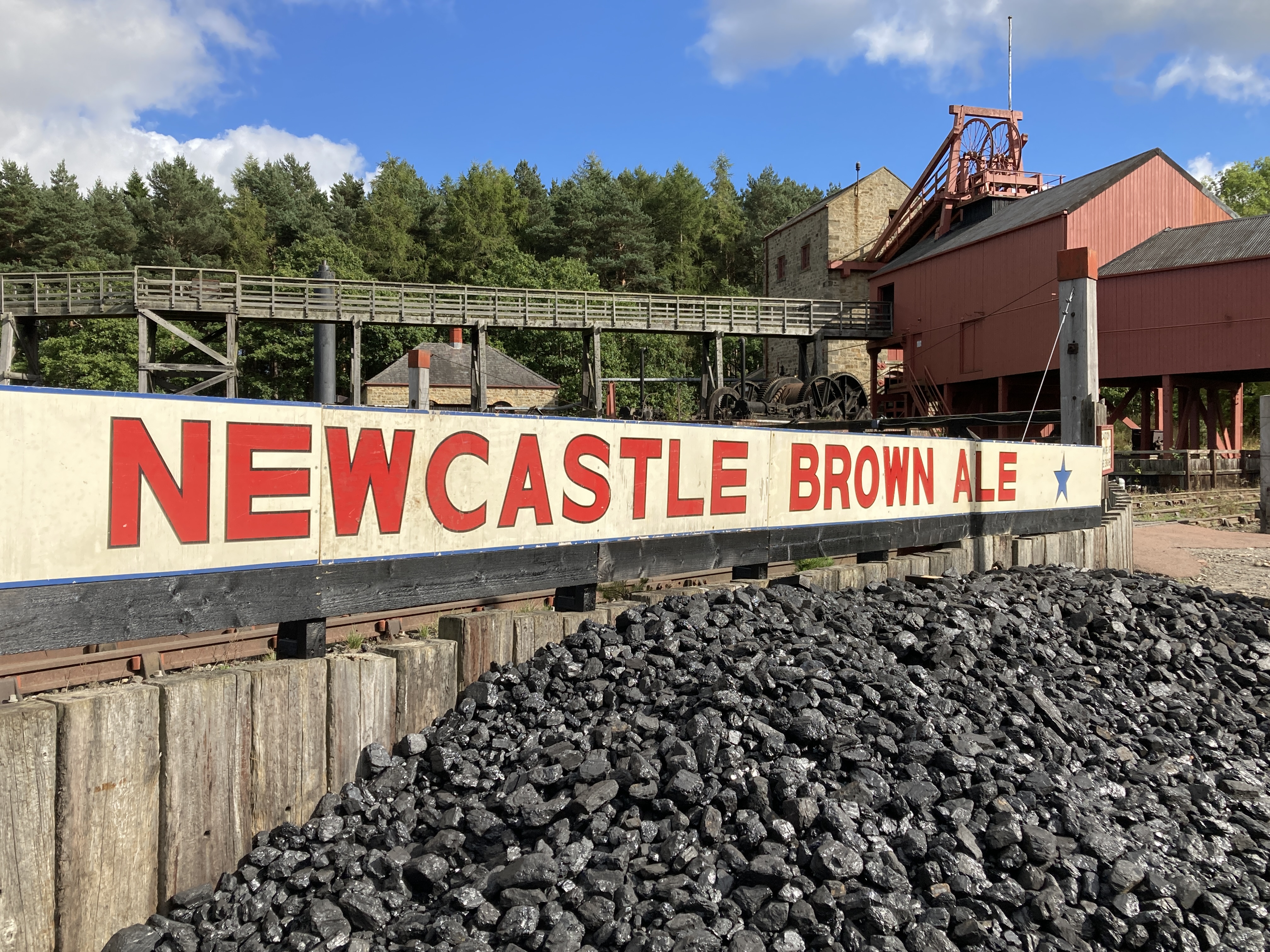

Below: As we are stockpiling more coal these days, to protect ourselves a little against interruption to supplies, the fence in the Colliery Yard has become a little short in height. A novel way of raising the effective height of the fence (in case anyone climbs the coal heap) has been found, utilising redundant advertising panels from Gateshead 10 to extend the vertical height of the fence.

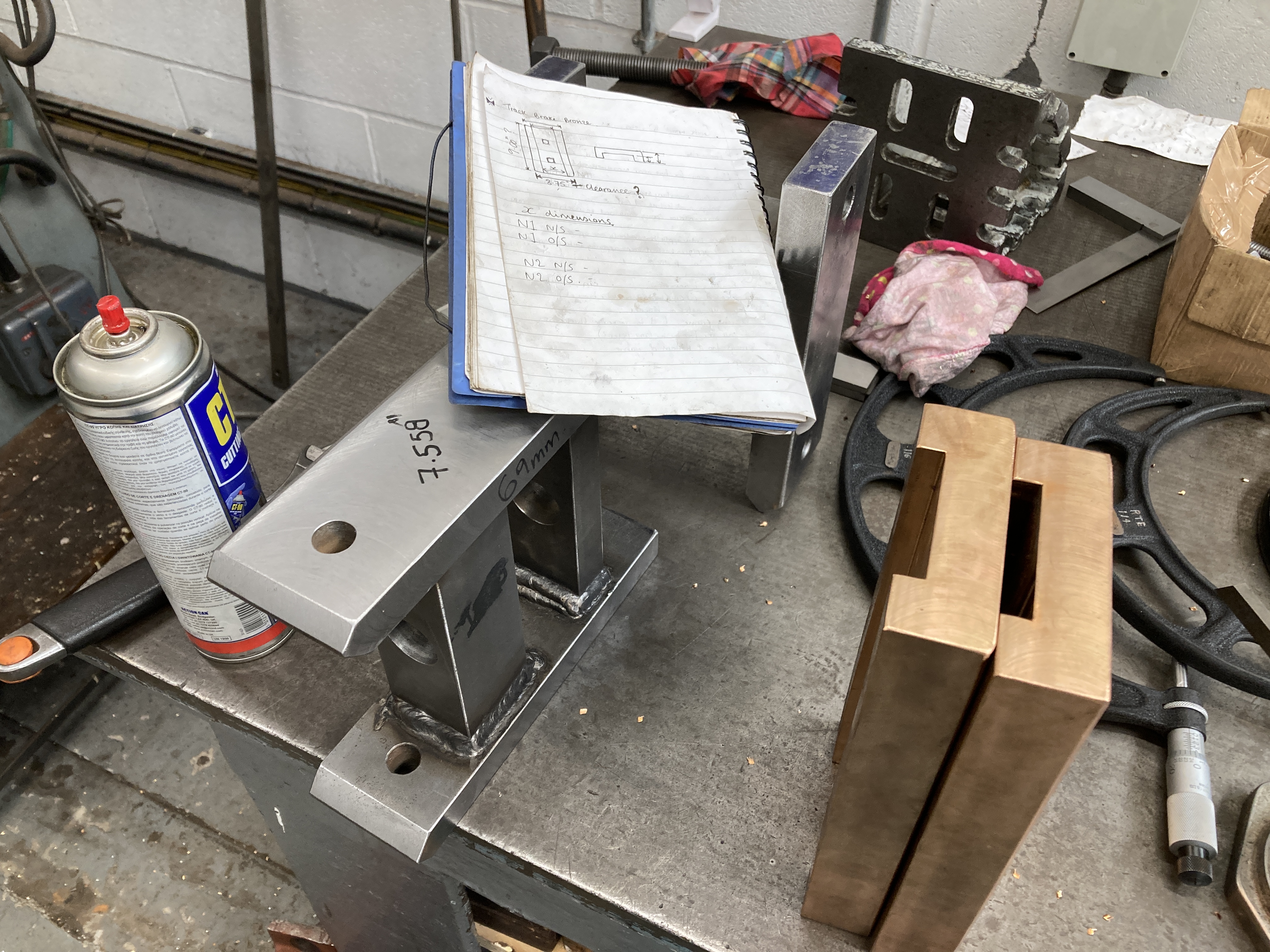

Below: The brake cross shafts for 10 are now being overhauled. The new shafts were made some time ago, but are now having the various pull-rods fitted to them.

Below: The fittings have also been overhauled, bored for bushing and their structural shape restored to original dimensions.

Below: To ensure the pull rods fit correctly, these have been cut to enable fitting and then welding, so that they are a close fit on the shaft. They are also pinned, so the holes for these are being restored to original, unworn, dimensions.

Below: Zoe is machining the slippers that fit onto the sides of the new track brake centre pieces (themselves fabricated in steel and seen in the last post).

Below: These slippers are fitted to each side of the steel centre, and in turn run in the guides attached to the bogie frames.

Below: One of the ‘brasses’ (usually phosphor bronze or gunmetal, rather than plain brass) is seen being machined to accurately accommodate the steel centre fabrication as a snug fit.

Below: A reminder of where these components are located – fitting into the guide shoes affixed to the bogie frames (in turn these have been carefully machined and set up to provide a parallel slot for the brake components above to locate into). Much of this precise engineering is hidden when the bogie is assembled, but these photos go someway to showing what work is carried out when so quickly described as ‘a mechanical overhaul’!

Below: Working at height has long been a topic of interest here, and in particular with accessing some areas of rolling stock (such as the roof or top decks of tramcars) which are beyond the reach of our usual ladders or towers. There have been in place, since 2005, the Working at Height Regulations, but in recent months, following some incidents within the heritage sector, a new focus on this subject has resulted. As we do not have a fall arrest system in the tram depot, we have tended to scaffold tramcars needing access to their roofs.

Below: Working at height has long been a topic of interest here, and in particular with accessing some areas of rolling stock (such as the roof or top decks of tramcars) which are beyond the reach of our usual ladders or towers. There have been in place, since 2005, the Working at Height Regulations, but in recent months, following some incidents within the heritage sector, a new focus on this subject has resulted. As we do not have a fall arrest system in the tram depot, we have tended to scaffold tramcars needing access to their roofs.

Readers may recall that Sunderland 101 was scaffolded for some time whilst the roof was reinforced and trolley planks fitted. We’re following the same route for Gateshead 10 – which has now been surrounded by scaffold and barriers in order that the roof can be cleaned, repaired, painted and the trolley base refitted. Once this work is complete, the tram will be lifted to enable completion of under-floor restoration, then, hopefully, be lowered back onto its bogies this winter.

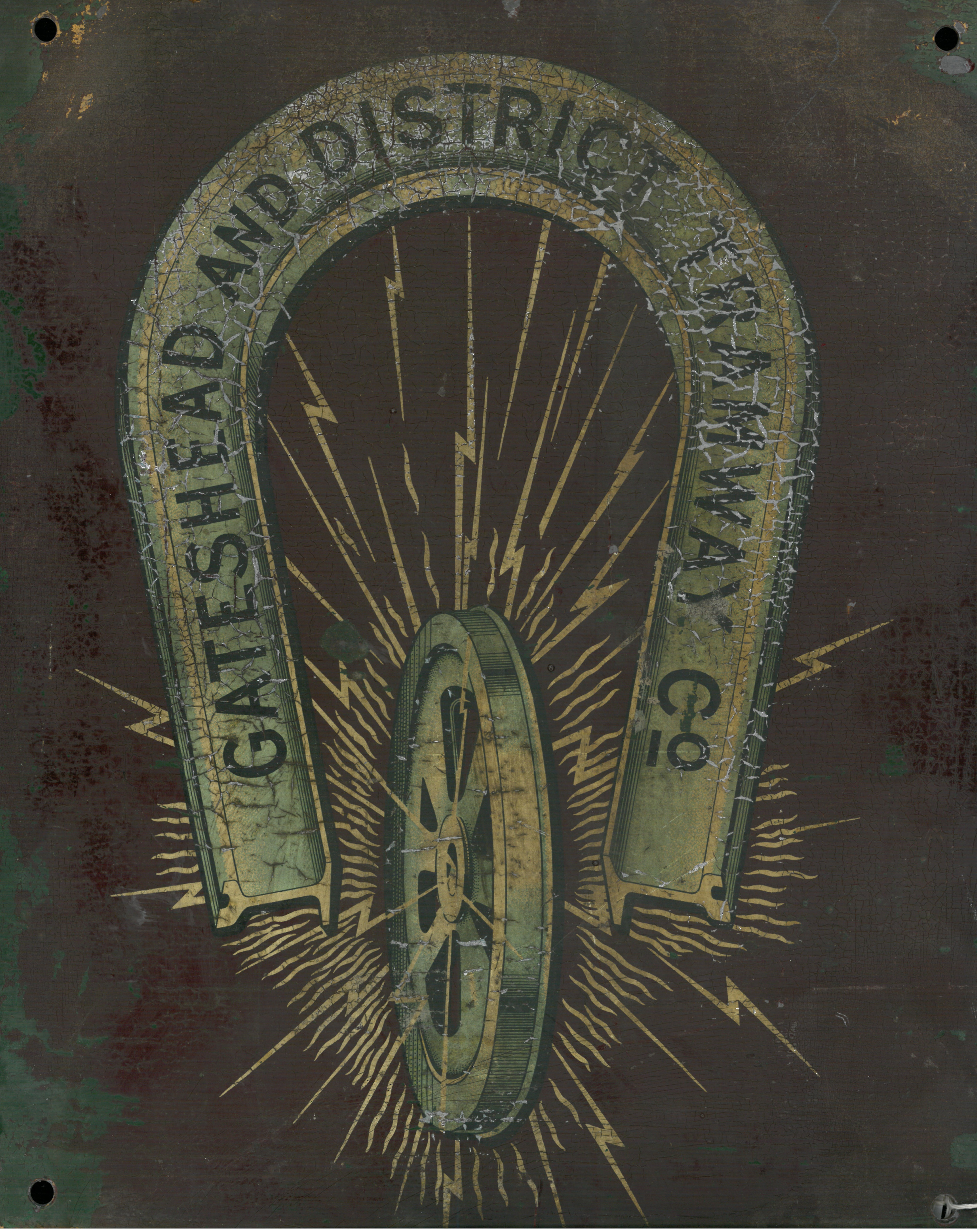

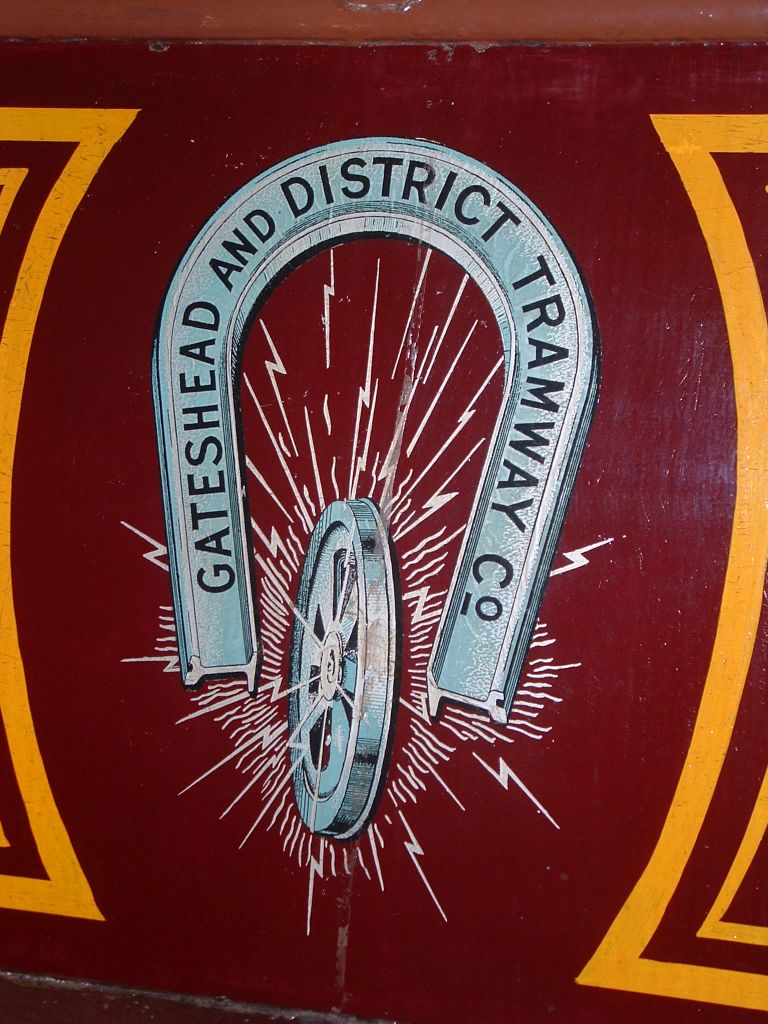

Once settled and tested, the gloss paintwork can be applied and the lining/lettering added. Contact has been made with Fox Transfers, in order to produce new Gateshead Tramways crests/logos, based on scans of originals within the collection here. I hope to feature some of this process on the blog in due course. The minimum order of transfers will be 50, so allowing for a small stock for archiving here at Beamish, we can make available these crests for others if they are interested. We may produce a small batch on crimson panels if there is sufficient interest, to enable some of the costs of this work to be recouped.

Below: A scan of the original crest, on a panel recovered from one of the trams that ended up with BR (judging by the green paint) I would imagine – so perhaps even off No.10 itself.

Below: A photo of the crest carried on Gateshead 10 in the 2000s… This was original old stock, applied as a vanish-fix transfer and so the colours can be considered reliable.

Below: A gallery of Gateshead 10/G&I 26 at work over the last fifteen years or so. It’s return is keenly anticipated and we very much look forward to completing this long-running project and seeing the tram back in service.

Recent Comments