T&I News 28 2022…

A late report this week, as we were struck down at home by a bug my one-year old son caught at nursery, and rapidly spread through the family! It is, though, very nice to find an inbox with lots of photos to show the progress being made by the team on several fronts, which I share here along with a narrative to explain what is going on…

VK 5401

Below: We start here with a view showing the demounted body of the bus, sat on its bespoke trolley and with internal structure in place to support it whilst it is repaired.

Below: The Dodge chassis is now well-stripped and the chassis ladder will shortly be sent for shot-blasting and painting/coating (depending on what it will fit into!). It will be finished in black and we will accept a modern process for this in order to give us a durable finish as nobody working on this project wants to see it needing doing again!

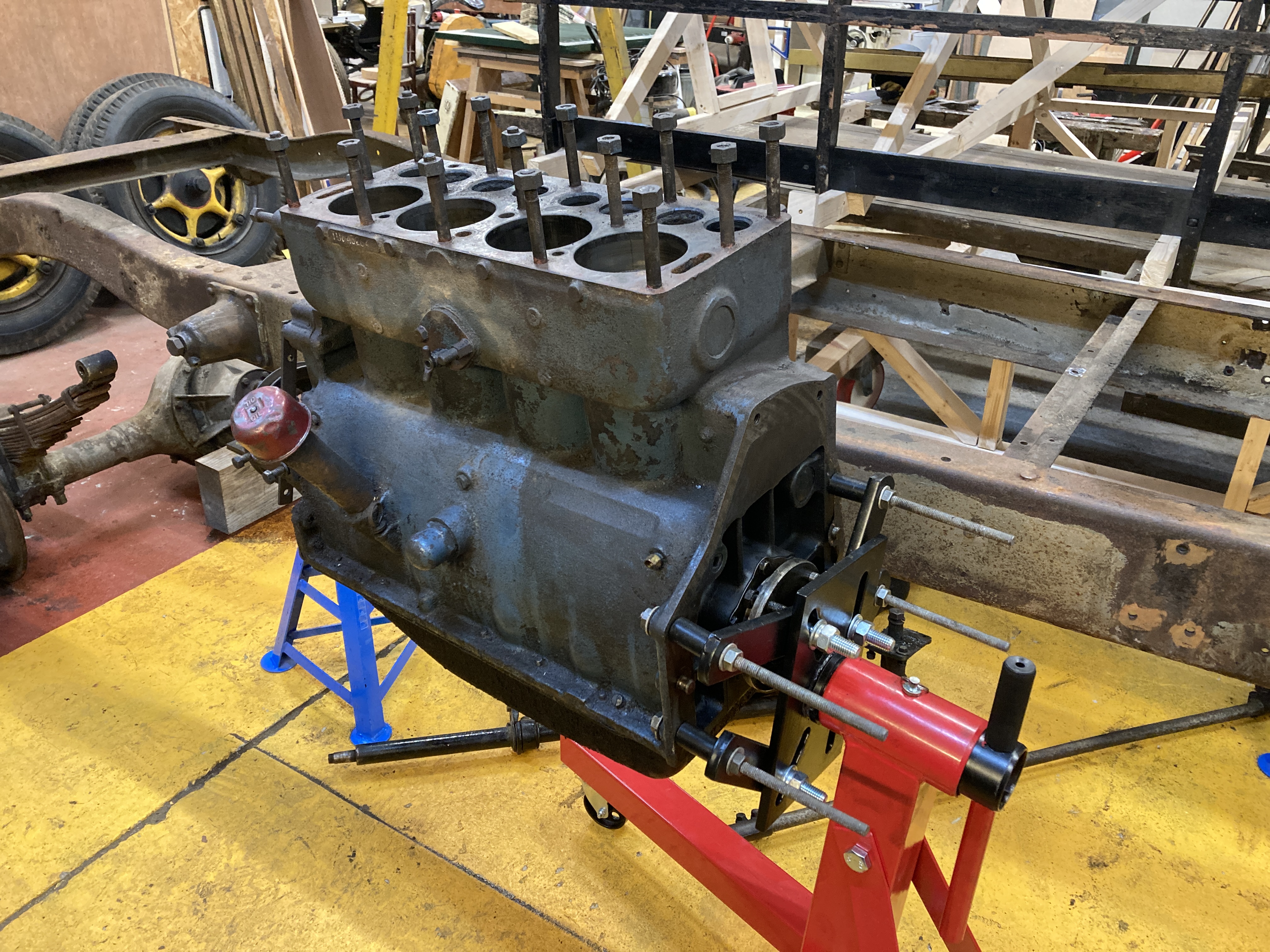

Below: The engine block is being stripped by Chris and team, and a list of the required repairs, renewals and replacements is growing as the condition of each component is explored.

Outdoor Works – Rowley Station

Below: The Steam Team have been continuing their work to improve the appearance of Rowley’s building and environs, including revisiting areas previously painted and improving them for accuracy, in part based on the study of some contemporary (to NER use) photographs, such as the one below.

Below: In repainting the columns, the style has been changed to better reflect what the image above appears to show. It does remain a longer-term aspiration to create replica screens to install into the arches – this would recreate what was actually present at Rowley, as well as extend the sheltered area of the station – something that might be useful in the future.

Outdoor Works – Waggonway

Below: A bit of tidying up yielded some spare Seaham Harbour Coal Drops stone blocks, that were placed at the end of the yard to form a dam against coal being stored in the area. This has opened up the view of the platform, moving the coal pile further east and reducing the obstruction to visitors who wish to study the locomotive and train when they are operating. Note the new yard gates that have been fitted in this location too. I still wonder about the water column and whether we should move it towards the shed, so we can actually use it…

Below: The steam team have been busy carrying out work on the exterior of the Great Shed, including repairing and repainting the doors and window frames.

Below: A new section of railing has been prepared and installed to block off a gap previously protected by chain. This finishes off the fencing in this area after many years, and adds another piece of detail to the scene.

Below: The deviation access path is progressing well, as shown here. A reminder, this is all being done by the same team of engagers who drive the trains and engage in the exhibits through the year.

Below: Over the road from the Waggonway, the COVID-19 era fencing in the Colliery (part of the recovery and reopening process and investment) has been adjusted by the team to make it more sympathetic to its period environs. This style has been copied from fencing in Weardale, and suits the area well. The team will be tackling other parts of the new fencing as and when time and opportunity allows.

Photos in this section courtesy of Jorden Sayer

Engineering

Below: North Bay Engineering Services are completing work on 721’s wheelsets. One of the centres has a radial crack around it, but this has not penetrated to the crank boss and it has been agreed that the tyre will act as sufficient counter to this, given the low-speed and low miles operation for the locomotive. Here are the wheels, with journals skimmed and the centres all turned-true. The new tyres, with an initial profile machined onto them, are in the foreground.

Below: Once the new tyres were shrunk onto the centres, the final profiles were turned, incorporating the back to back/back to front measurements that had been calculated for the locomotive (which is quite wide-framed). With this work done, the wheels are set up (as seen here) for the crankpins to be tidied up and turned true. David Young has made new brasses for the coupling and connecting rods, so these will be machined to the required dimensions and clearance once the wheelsets are back at Beamish. Similarly new axlebox brasses have been cast and will be machined to match the journals.

Photos above courtesy of North Bay Railway Engineering Services

Below: A progress view of the first of Gateshead 10’s bogies receiving its top coats of paint in the RHEC.

NER 559

Below: The boiler shell and firebox flu have been prepared and now sent for Non Destructive Testing (NDT), as seen here. It is a reminder, when seen like this, of just how small this locomotive will be!

Photo courtesy of North Bay Railway Engineering Services

More 4mm scale North Eastern waggons

Modellers will be pleased to see Accurascale’s further announcements regarding it’s range of coal-carrying waggons. The launch for the latest batch was filmed at Beamish and can be seen here:

At the weekend, Rapido Trains announced an NER H/LNER Y7 would be added to their range, and this on top of Heljan/Locomotion Models recent announcement that they are producing the Tyne Quay electric locomotives in 4mm scale.

Until recently I have been receiving regular email updates.

I have not had any for quite some time.

I have tried to subscribe again but it keeps coming up with an error message.

Can you help

Thanks Stephen

As reported by Stephen Howarth, applies to myself.

Many thanks, Graham