Transport & Engineering Diary September 2025 Part 1

For the first part of the month, here is a fleet/site round-up, to record progress on numerous vehicles. Readers will have noted the previous post with an update on Dunrobin’s boiler. The valve gear/motion for this locomotive is also largely complete and the hydraulic test for the boiler is booked for mid-October.

Steam Elephant

Below: Preparation for the boiler to be tested/inspected by the insurance company surveyor have continued – here is one of the mud doors fitted – note the white paint-pen labels to ensure doors and plugs return to the hole from which they originate.

Below: Steam Elephant’s safety valve has also had some attention, the valve being lapped into the seat to ensure a good fit when the valve is closed.

Below: Numerous items were showing the effects of use and have been cleaned and inspected, ready for fitting.

Puffing Billy

Below: The original hand/parking brake nut (which is at the bottom of the vertical handbrake shaft) was replaced recently – the worn original is on the left, the sturdier replacement is on the right.

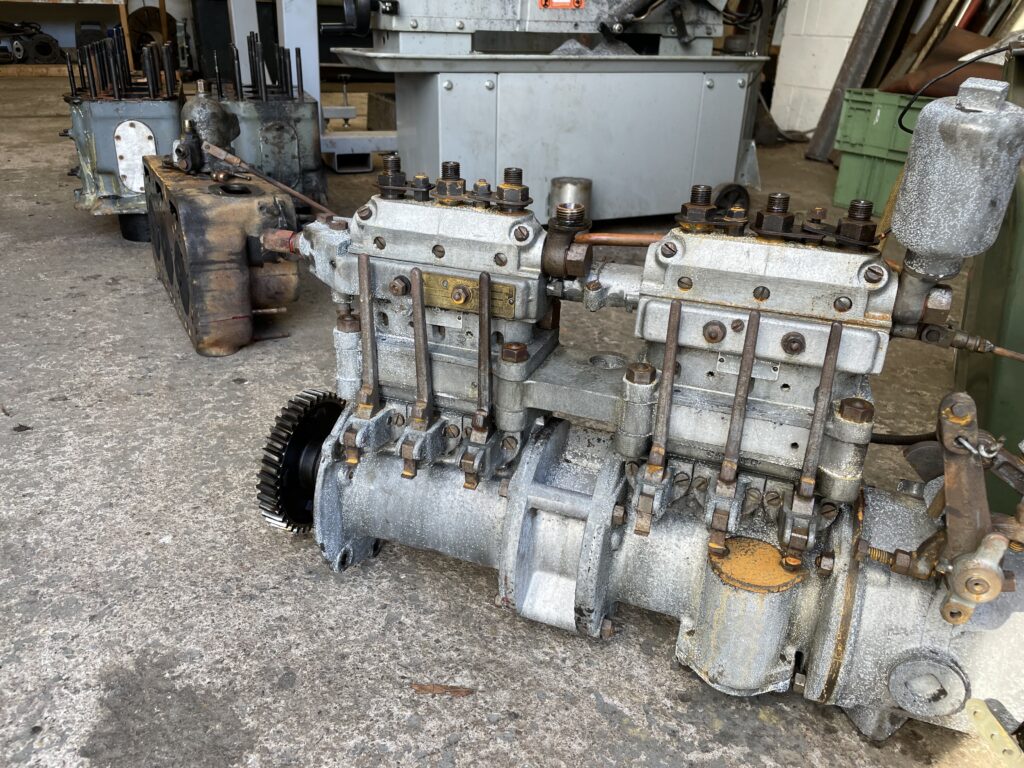

Rotherham 220

Below: For a little while, 220 has had a ‘knock’ emanating from its engine. It has been decided to reduce its operating level in the short-term. We have a spare 6LW (seen here) that is being dismantled to yield spares, the aim being to have two good engines, out of the parts of 3 and ensure one is ready to be transplanted into 220 to reduce its down-time. Whilst out of service we hope to find some funds in order that the seats can be re-upholstered. Here Phil applies some persuasion to the donor engine as it is dismantled for spares. We also have a 5LW available for Darlington 4 and are always looking out for spare engines/gearboxes/differentials for our vehicles, in order to build up a stock of potential spares for the fleet.

Below: A working spare 6LW has just been collected following donation to the museum, and this will be overhauled and fitted to 220, to release 220’s own for overhaul/spare as and when this might be required.

Below: The newly arrived engine was soon broken down for overhaul too. Whilst it was nominally operational, there was little point in putting an unknown engine into the bus, and the effort to overhaul this example will hopefully result in many years of reliable service in 220.

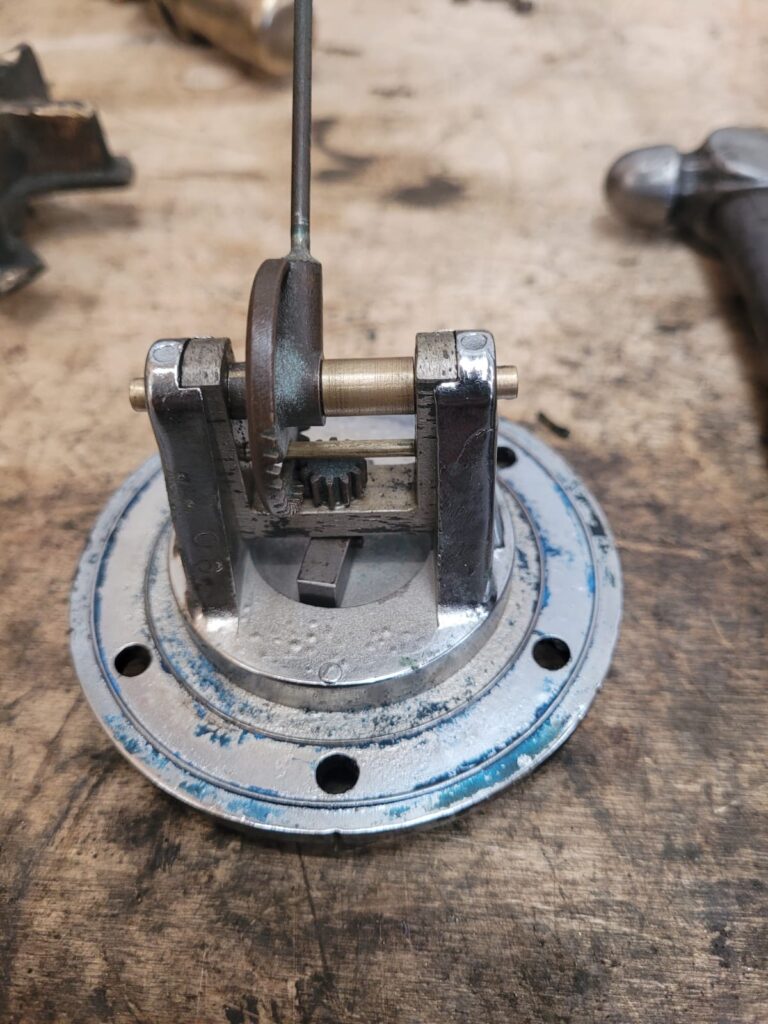

Newcastle City Fire Brigade Leyland Cub FK7

Below: In preparation for further operation, the fuel tank has been removed for cleaning – up to now the fire engine has used a temporary fuel tank with transfer pump. The capacity indicator and float gauge was stuck, so has been removed and overhauled for reinstatement in the tank once this returns from the contractor carrying out the specialist clean-up.

Newcastle 114

Below: Spot the difference – compared to the previous post! The black beading is also being refreshed, whilst the yellow panels have been flatted in readiness for another coat of paint (as there is time to apply this). The signwriter is booked to visit later this month, in order to restore the ornate lining on the yellow panels as well as refresh the dash panel numbers. After this, the tram will be prepared for varnishing.

Blackpool 31

Below: This tram was failed following damage being discovered on one of the truck bolster side plates. We were keen not to lift the tram (as the jacks are in use by 10 and we didn’t want to have to spread all of the parts across the depot) so Mick and Ian have managed to remove the damaged plate (it forms a side plate to the side of a channel for the bolster assembly between the bogie sides) and rather than attempt to repair this, will manufacture new plates and insert these back into the bogies. It would appear that an old fracture propagated into a break between bolts, whence the decision to completely remove the material and replace it. Various items from the bogie had to be removed in order to access the repair, including the brake gear shown here. 31 isn’t due a mechanical overhaul just yet, so whilst it was tempting to seek to re-profile the tyres, this would not have been practical given the resource/space available to us at the moment.

Below: We are rather short of available tramcars whilst Blackpool 31 is under repair, with 16, 196 and 264 holding the fort. Gateshead 10’s overhaul continues (as reported elsewhere in this post), and 114 awaits overhauled controllers and completion of its partial re-paint ahead of its 125th year in 2026. Lisbon 730 continues to present challenges and the discovery of a mis-mesh between motor pinion and axle gears means that we may have to lift the tram and remove the truck to further explore and then resolve this issue. The return of Gateshead 10 to service is the priority, followed by Newcastle 114. Blackpool 31’s mechanical overhaul (and refresh of the body) will wait until Sheffield 264 is re-tyred (once Gateshead 10 has settled into service) and Sunderland 16 also has to fit in with these, again for re-tyring (probably quickly following 264 through the process). We will look for an opportunity to progress 730, the entry into service of which will allow 196 to be retired pending a comprehensive overhaul.

Gateshead 10

Below: The new spring cups and control links/pins have been completed and are being fitted to the bogies. This will now enable the brakegear to be reassembled and the motors re-fitted. The plan is to tow both bogies to accumulate some miles on them and enable the components to be inspected and any remedial work carried out before we commit to fitting them back underneath the body.

Daimler CK Lorry

Below: The flywheel has been removed from the engine crankshaft. A bespoke puller was made and a substantial amount of pressure was required. Phil described the process as ‘apply some strategic hammer blows and more tightening of the centre bolt, then go and do something else, come back and repeat – within a couple of hours, it came off’. The engine will now be mounted on an engine cradle for further dismantling and overhaul, though this is not a high-priority project and it is likely that the engine from the SHEW car will take precedence in terms of veteran vehicle overhaul work in the medium term.

A suitable ring gear and starter motor-type has been identified to suit the Daimler, as there is space to accommodate electric starting – something that is operationally desirable and also makes the process much safer within the museum environment. Such installation will be entirely reversible, should the vehicle ever be required in a purer form, but given the level of renewal the cab and body will require, as well as sections of the chassis, this is felt to be a small compromise in this regard – we also intend to restore the original wings (it was back-dated to look older than it was, when first installed in the garage at Beamish).

Crosville 716

Below: Visitors may have noticed the absence of 716 over the last month or so. The rear doors became damaged, so it returned to Gardiner’s in Spennymoor for repair, where it was determined that it was easier to manufacture and install new doors – resulting in these also needing repainting and signwriting. With this work completed, the bus has returned to Beamish.

Darlington Corporation Bus Shelter

Below: After something of a hiatus, work on the site on which the ex Darlington Corporation bus shelter will be erected has commenced. The rather atypical building (for the region) on the site opposite Pockerley Tram stop has been dismantled for re-use elsewhere on site, and the ground will soon be cleared and a concrete base and new fencing installed. Meanwhile, the shelter is moving to the fabrication shop for some modifications and assembly, before installation on site, painting and glazing. This project is supported by the Association for Industrial Archaeology and has been delayed in delivery when the original site proposed became unavailable. This stop has become a busy one on the bus route, so the provision of a shelter will, I am sure, be a welcome one.

Below: The bus shelter canopy outside the fabrication shop for completion of modifications and final assembly.

Narrow Gauge Railway

Below: For various reasons, work on the narrow gauge has slowed down, but three sets of of turnout (points) have received new ‘timbers’ (steel I beams) to replace decayed wooden sleepers that also functioned as sliding surfaces for the switch rails and mounting points for the levers too. This should give us much more positive closure, when operated, and also improved support to the track in these areas as well.

Waggonway

A new coach for the Waggonway has reached the design stage – I’ll illustrate and feature it separately, as it will be covered in some detail, but it should restore capacity at the Waggonway for the summer of 2027 onwards.

Workshop development work

Below: The old Erecting Shop building is being re-wired with revised power supply for the lighting and limited socket installation. The space is being adapted as a vehicle store, for long-term projects and some of the working collection (which has often had to be based outside, or tucked into any space we could find for it). This has meant Sunderland 2 being made mobile, and this is now in the area that will be the new Vehicle Joinery, which is going to have a new floor surface, new lighting and be fitted out with the woodworking machinery from the Erecting Shop.

A new Local Exhaust Ventilation (LEV) system is being installed, so that this aspect of work remains compliant – management of dust exposure has been of particular interest to the regulators, and the old system was no longer easily maintainable to the required standards. Once the work has been completed (at considerable cost!), Darlington 4 will enter the workshop for completion, then Sunderland 2 will return (as it is temporarily parked there) for completion of the conservation/restoration work. Future projects in this area will include railway waggons, the Dodge bus body and a lot of street sign posts, as well as supporting work being carried out in the adjacent tram and bus depots.

More postcards from Samson…

Below: Samson’s holiday in Wales continues, and it made a trip onto the Welsh Highland Railway in order to visit the Welsh Highland Heritage Railway on the other side of Porthmadog. These photos show it crossing the Cambrian line by way of the famous flat crossing, and later on making its way back to Boston Lodge across Britannia Bridge in Porthmadog, in the face of the deteriorating weather.

Samson will next appear at the Ffestiniog & Welsh Highland Railway Bygones Weekend, after which it will be stored pending overhaul this winter. It will return to Beamish next year, date TBC.

Photos by Phil Doran, Paul Jarman, Clare Oates and Phil Smith

Just an idea for the 27th i know steam elephant is not yet ready to work on the waggon way but any chance it can in the waggon way yard rather than inside the shed.