Transport & Engineering Diary October 2025 Part 2

Looking back at the folder for ‘October blog images’ I was surprised to see just how many photos there were in it! It has certainly been a busy month with lots to see, and one that the weather has certainly helped – the short days of winter are perhaps less photogenic and the work undertaken tends to be more routine. However, there is a great deal taking place and as ever, here is a selection of projects and programmes that have been taking place in the last two weeks. In addition to these, the PW team have been carrying out re-sleepering work in the Colliery and there is a great deal of progress in the sorting and preparation of Overhead Line Equipment (OLE) for the Tramway (and future trolleybus route).

Rowley Station

Below: Work is underway to clear the embankments of vegetation in order to open up the views of the railway, from the road alongside the cutting (from where this view was taken).

Below: The signalbox has been scaffolded for repair and redecoration over the coming months, and in order to improve its appearance for the station’s 50th anniversary since it was reopened formally, next year.

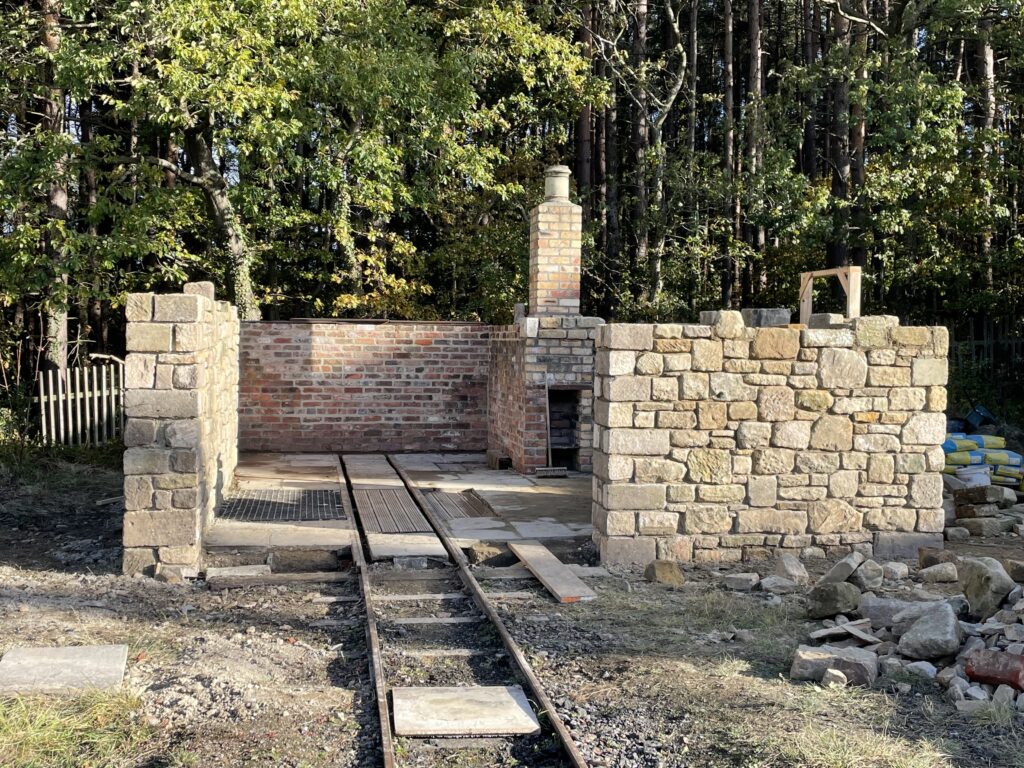

Narrow Gauge Railway

Below: The narrow gauge loco shed, which will usually house Samson, is rapidly progressing, with door and window apertures now being set out.

Below: These two views, as at the end of October, give a good idea of the style and shape of the shed, now that all four walls have reached a reasonable height.

Below: The shed site had a visitor in the shape of Glyder, which was steamed and used to ensure sufficient clearance would be available for larger locos – as mentioned above, it will usually be Samson’s base, but for annual inspections, it is useful to have access to a pit (and one ideally under a roof!). Having confirmed clearances, the shed will now be scaffolded as the higher sections of wall construction commence.

Below: Glyder also tested all of the new narrow gauge track formation and repaired turnouts, as well as moving some stock into position for the winter.

Gateshead 10

Below: In the middle of the month, the final coil spring and associated cup/control arms were assembled onto the bogies, completing this part of the process.

Below: With the springs in place, the brakes could then be attached to the frames, as seen here, complete with new brake blocks.

Below: With the motors fitted, the collars that establish the motor position in relation to the wheel boss back-face were then installed.

Below: Two views of the overhauled motors in position, with the torsion reaction bars fitted to them, ready to be drilled in relation to the bogie frame and torsion springs. The bars were then be removed and painted before final assembly.

Below: The bogie frames were drilled for the new holes that secure the torsion reaction bars. The old holes had previously been welded up, to enable new holes to be drilled accurately for the refurbished components.

Below: Temporary assembly of these components shows the principle rather more effectively than can be described.

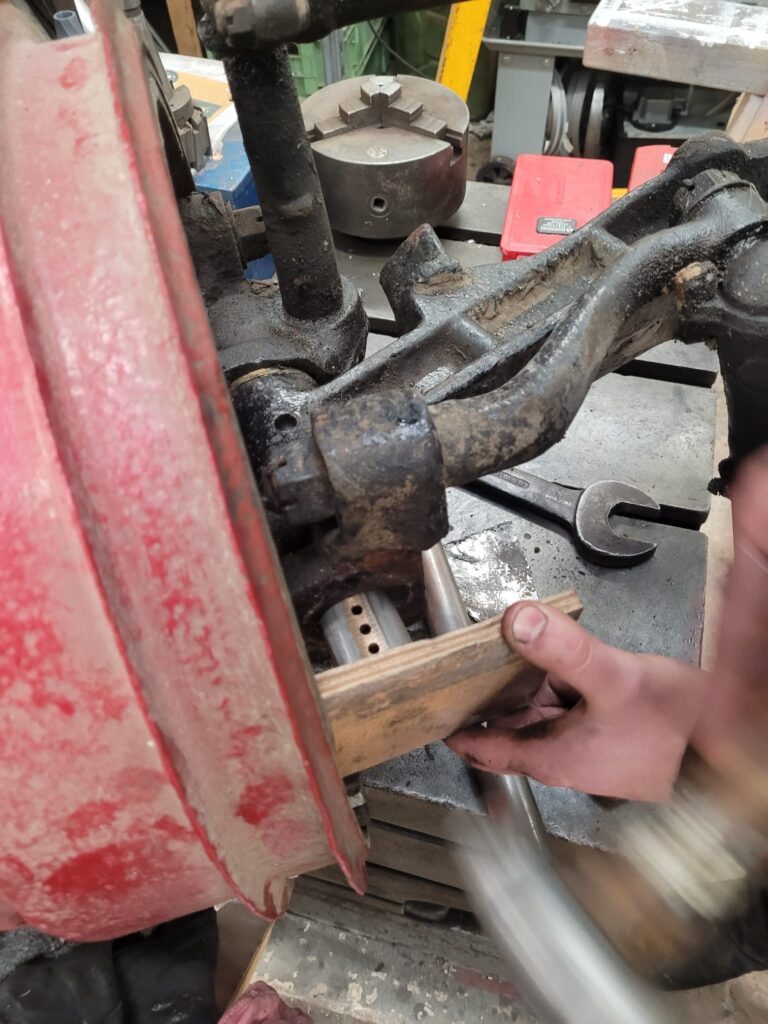

NGTC 688 ‘SOS’ Bus

Below: The front axle was dismantled in order to allow it to be straightened. The kingpins were withdrawn using a hollow ram, which exerted between 12 and 18 tons of force to remove them cold.

Below: The front axle was then moved to the press and straightened, shown in the two views below depicting the during and after process.

Below:

Below: The damaged mounting pads for the front axle (the springs themselves are away at a contractor for overhaul). These required complete replacement…

Below: A sequence of photos showing the manufacture of the new pads and wedges now follow.

Below: This wedge was made in order to set up the machining operation seen above, where several taper cuts were to be made, all requiring a consistent angle.

Below: The finished items, primed and ready for painting.

Below: Old and new components together, after the new ones had been painted.

Dunrobin

Below: As mentioned in the last post about Dunrobin, the boiler is being trial fitted to the frames, in order to allow work on the backhead fittings to progress and ensure the overhauled vessel fits correctly. The result certainly looks exciting, though the boiler will be removed for fitting of the smokebox and steam test etc. The refurbished brakegear is also being fitted – the hangers, cross-shafts and pull rods are visible in this view.

Below: This post closes with a photo from one of the Halloween evenings, showing Weardale 909 at Redman Park as its passengers board for their journey back to the Entrance. This bus has become a familiar and welcome sight around the museum, and it seems to be very popular – certainly a vehicle that was well worth adding to the collection and the working fleet.

November should bring further progress on Gateshead 10, the narrow gauge engine shed, ongoing re-commissioning work on Steam Elephant and hopefully completion of the new joinery, to enable Darlington 4 to move back in for completion of the repairs to its body frame.

Photos by Duncan Ballard, Phil Doran, Paul Jarman and Sam Telfer

Are there any more running days for the narrow gauge this year?

Hi Matt

There are no running days planned, and Glyder will be stripped for winter inspection and maintenance fairly soon. Samson is on loan to the FR at the moment, and the Waggonway will shortly close for the winter to allow winter maintenance there too. With the weather getting colder now, we tend to witnerise the steam fleet to protect against frost damage etc. too.

Best wishes

Paul

Thanks Paul

Great to see that work has restarted on the narrow gauge loco shed. will be a really useful addition to the narrow gauge railway.

Was Glyder the first loco to enter the shed?

Gary

Hi Gary

Glyder has used the pit in the partialy completed shed for a number of years now, as has Samson and the visiting locos for events. KS 721 has also been there during its clearance checks a few years ago. As for which loco will be first in once the shed is completed – time will tell!

Best wishes

Paul

Hi Paul!

Appreciate it’s probably the last thing on mind when the busy pre-winter work is on the cards – what sort of transport provisions will be on hand during the Christmas evening events, please?

It’s my girlfriend’s first ever visit so I’m very eager to get as much done as possible!

All the best,

Jordan

Hi Jordan

During the evening events it will be trams and buses – usually three/four trams and four/five buses depending on how many visitors are expected. I would imagine it will be more buses than trams, given the weather we are having at present, and we usually look to having a few hired-in vintage buses too – but what these are likely to be very much depends on what the operators/owners have available at the time.

Best wishes

Paul