Transport & Engineering Diary August 2025

This month has passed by in something of a blur, with lots happening, and therefore quite a bit to report. The separate post regarding the SHEW car will hopefully have kept readers interested, and there is a forthcoming article to come, with the newly acquired Dene motorcycles to be discussed…

Dunrobin

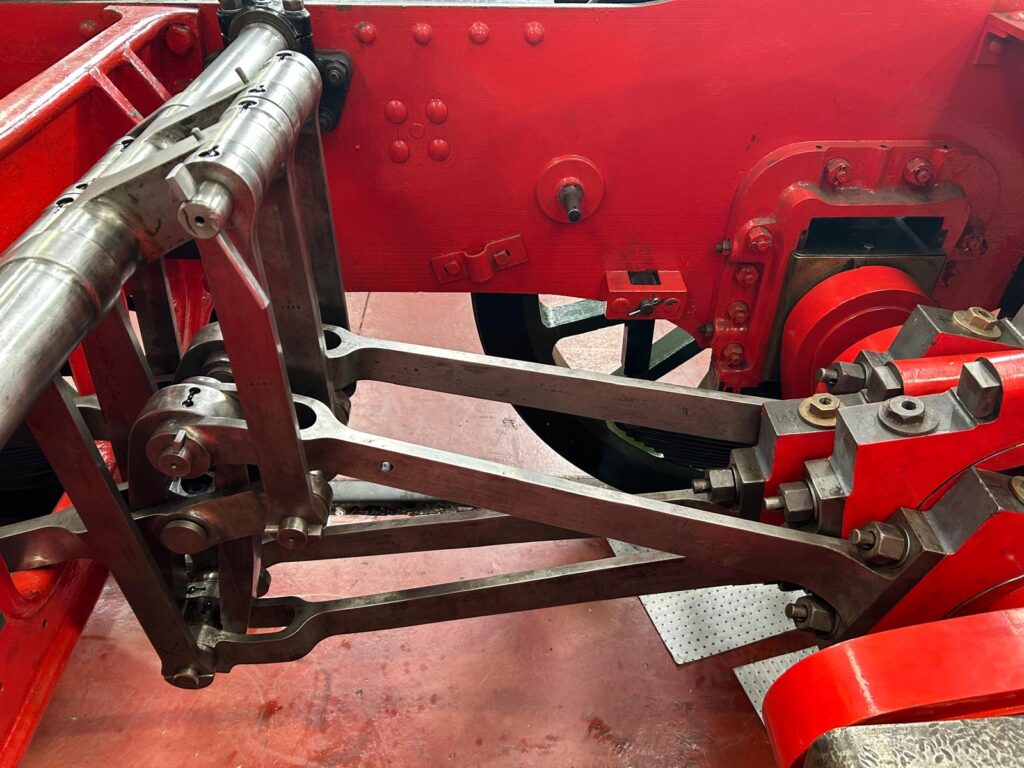

Below: This recent photo of Dunrobin shows the overhauled valve gear being assembled (connecting rods yet to be fitted). The absence of the connecting rods creates an impression of space between the frames, but once the bell has been reinstated, and some form of mechanical lubricator concealed here too, the space (including that needed for the movement of the rods and valve gear) soon fills up.

Some of the final parts for the boiler have also been received at Bridgnorth, to complete the replacement dome assembly and allow this to be permanently attached to the boiler barrel.

Steam Elephant

Below: Steam Elephant is now awaiting its final boiler examination/test before being commissioned back into service as a working locomotive once again. It will make a very welcome returnee to the operation and we hope to have it in action during the October half-term week, where the Waggonway will round off the museum’s Railway 200 event contribution, hopefully with a very special visitor to work alongside the resident locomotives…

Below: Assembly of the overhauled valve gear was completed early in the month, so a visit from the boiler inspector is the next step towards returning the locomotive to operation.

Gateshead 10

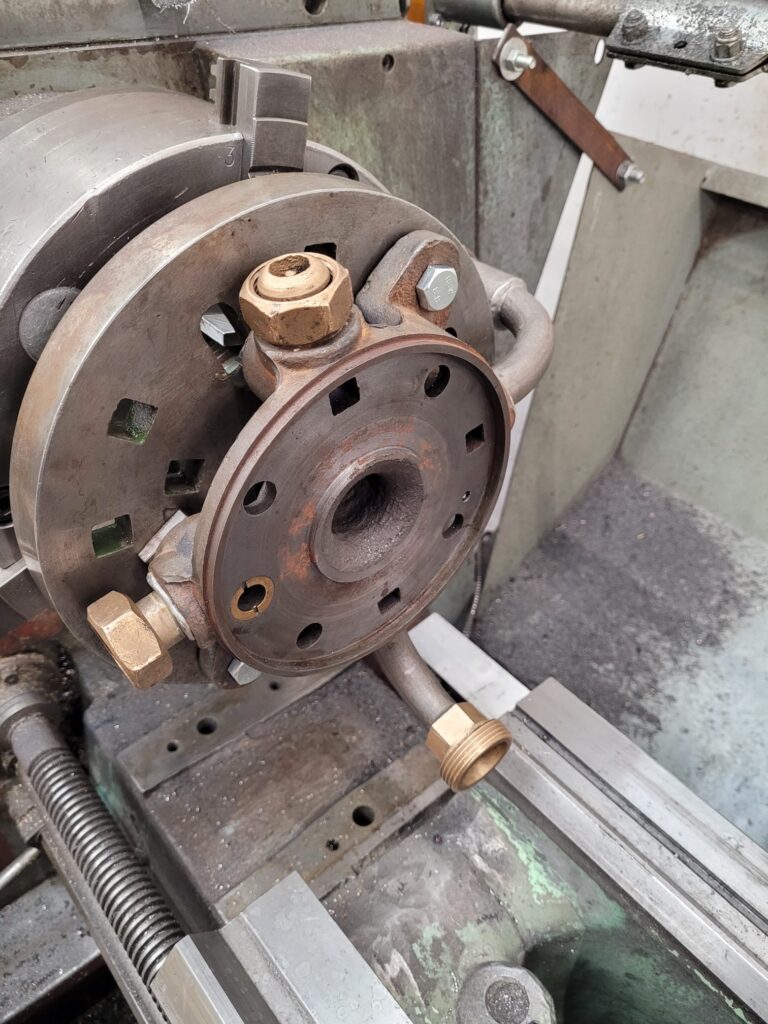

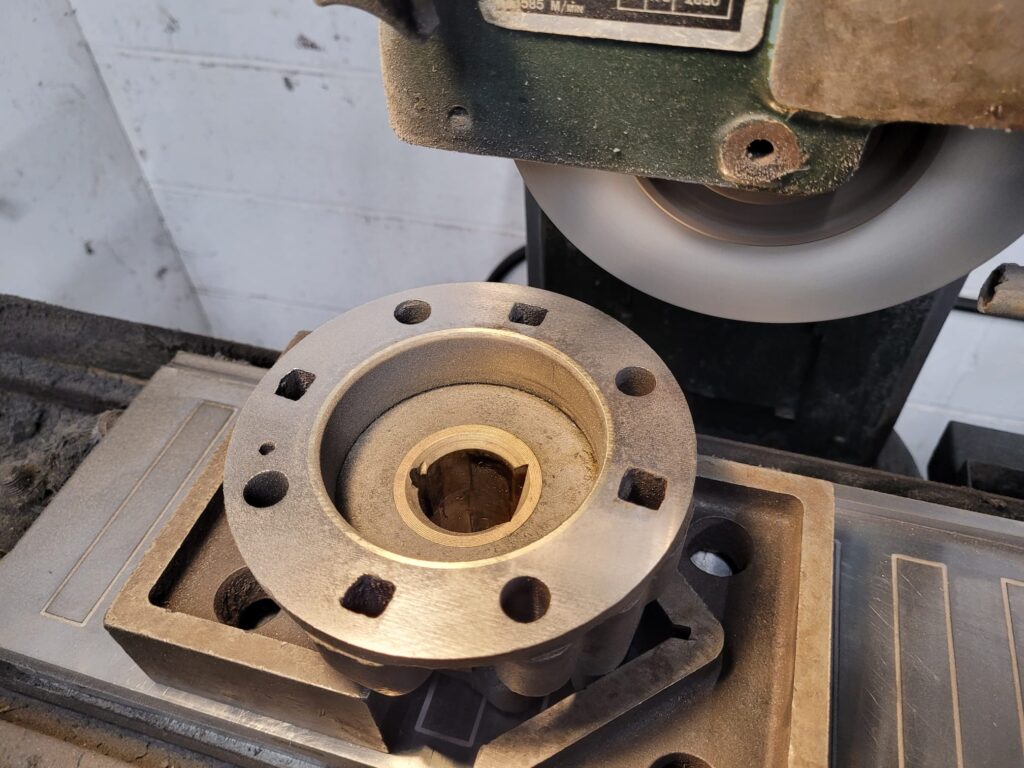

Below: The air brake cylinder from the tram was dismantled in order for the bore to be inspected. There is some evidence of corrosion and surface degradation so this cylinder has been bored, in order to restore its concentricity and remove the surface impurities.

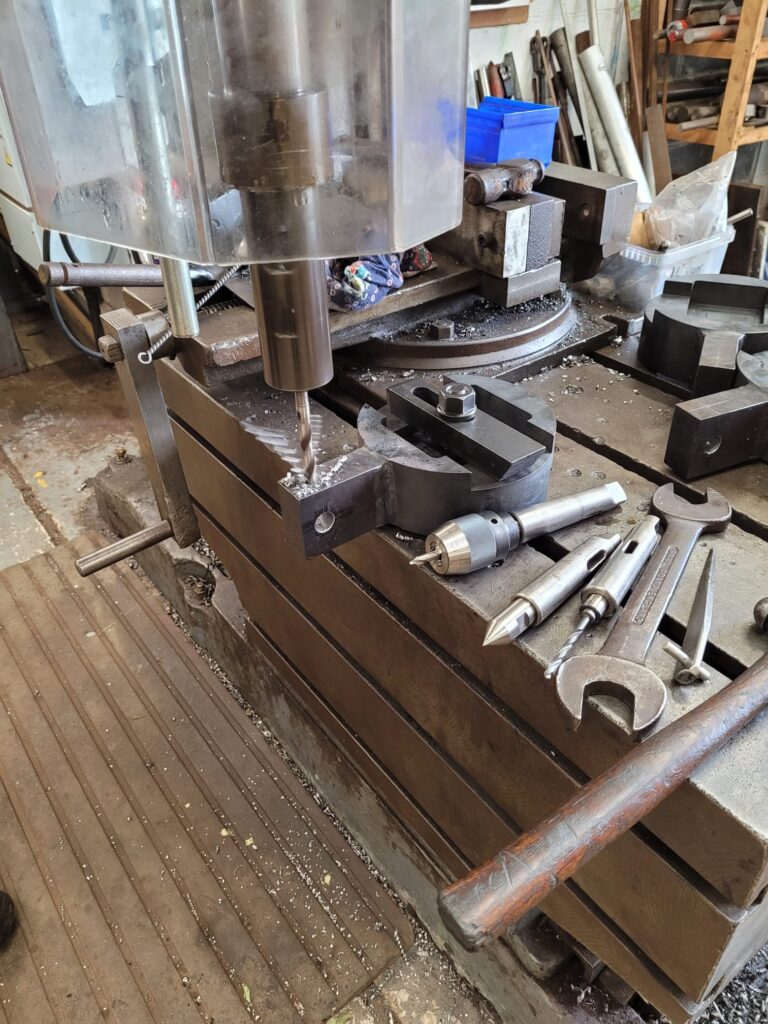

Below: The cylinder mounted on the lathe in a four-jaw chuck and with the boring bar in position before the first cut is made.

Below: Nearly 80thou was removed to restore the internal bore to a circular profile – here is the finished piece.

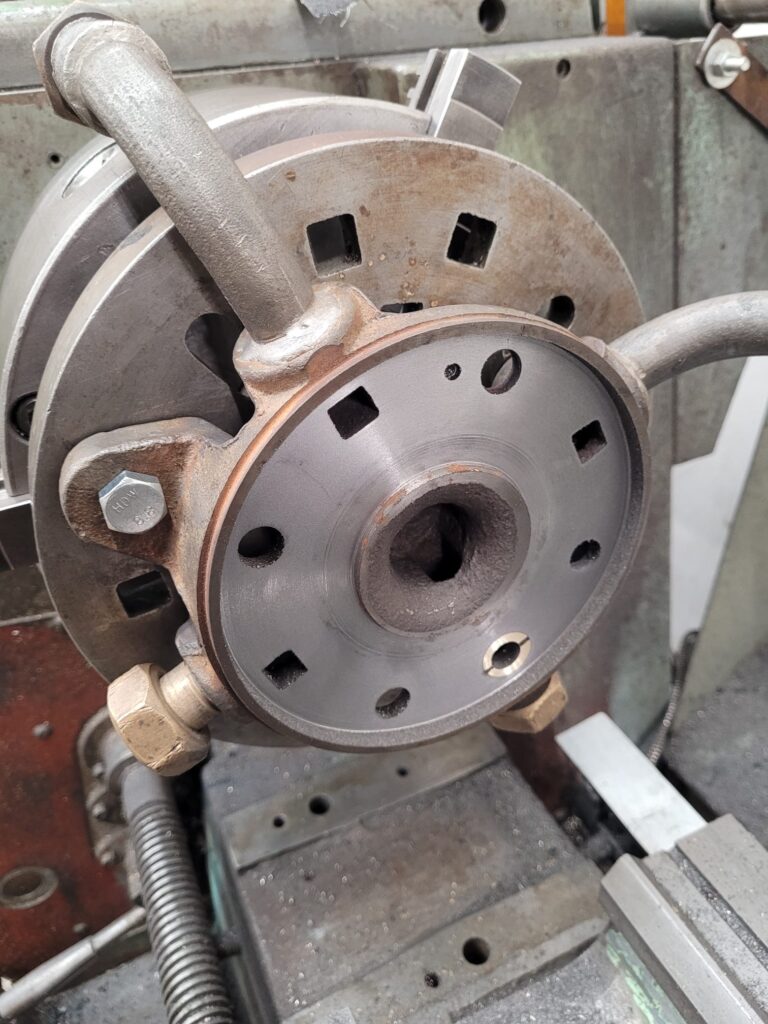

Below: This is the brake piston – the end nearest the camera is the piston head, with seal visible, and the flange to the rear of the spring is what bolts onto the rear of the cylinder, through which the piston rod passes. The cylinder is single-acting (the air acts on the piston in one direction only) so the large spring is to return the piston once the air pressure is released.

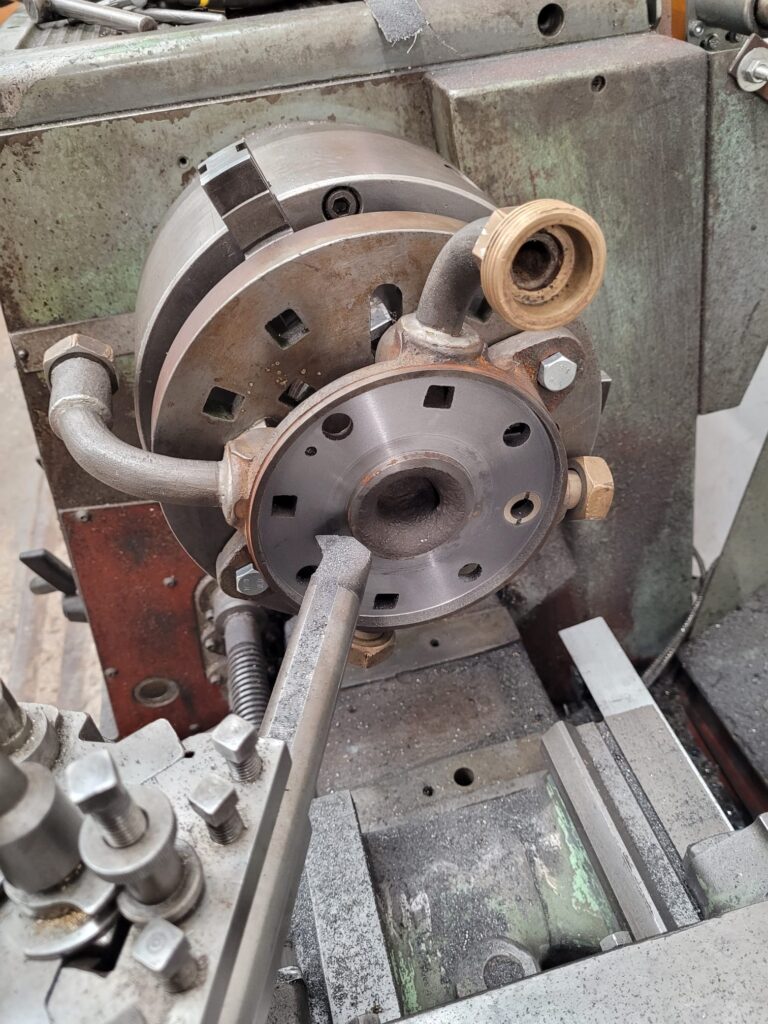

Below: The brake valves continue to receive attention to – again to restore the mating surfaces between the valve components (through which air can leak and escape). This sequence shows the valve assembly on the lathe before machining, during and then after work was completed.

Below: The corresponding valve body has also been treated to a visit to the surface grinder, with 10.5 thou being carefully removed to restore the surface accuracy. The two views below show the component before, and after.

Below: We now return to the coil spring cups, that have been manufactured from new, for the bogies on Gateshead 10. Firstly, we see the components prepared for welding, complete with run on/run off tabs (these enable the weld of the actual material to be continuous, without a stop/start on the piece itself, reducing cratering on the weld that will remain – they are removed and dressed off after the welding is completed).

Below: The completed items in the kiln (at the pottery at Pockerley!), ready for heat treatment to stress-relieve them.

Below: After firing…

Below: The heat treated parts were then wiped with oil, and this reveals the black oxide finish from the process.

Below: The coil spring cups were trial fitted and then marked up for drilling.

Below: The cups, complete with the welded lugs, are seen after heat treatment (part of the welding process) and with the holes drilled for the pins that locate the control links.

Below: With the linkage holes drilled, the next step was to drill and tap the lubrication points – part of the overall objective to improve lubrication on the tram and consequently reduce wear and tear. These parts are now being painted in readiness for fitting onto the bogies.

Below: Once the holes were drilled, the parts were shot-blasted to prepare them for painting, and a dye-penetration NDT process was applied, to prove the integrity of the welds – this is shown here by the white residue that it leaves.

Below: Following priming, the cups have been painted and are seen here drying on their clothes line. Behind them are the new air tanks for 10, which have been painted in the interior shade of brown used on such components (they are located beneath the seats).

Below: The brake rigging has been shot-blasted and primed, after inspection for remedial works needed. It is now being painted in the standard underframe red/brown colour.

Below: The overhauled compressor has been refitted to the underside of 10, and the brake swaybar assembly will be installed next. The air pipes have been inspected and are deemed suitable for further use.

Town Garage

Below: There have been a number of mentions of the Town Garage display, and the development of a scheme to motorise some of the machinery in order that it can be operated (slowly!) in order to bring some life to the exhibit. Here is the Blackstone oil engine, located to the rear of the garage area and which will be driven by electricity, and in turn enable it to drive the line shafting via the belts that can be seen here. For some reason the engine was installed on a plinth that does not align with the line shafting, so this is a challenge currently being faced by the team, who have now overhauled the gearbox and bedplate for the motor-drive assembly.

Rowley Station

Below: The tired steps to the signalbox were closed earlier in the season, and the replacements (made in quality timber) have been manufactured and installed. They are seen pending painting. It is planned to scaffold the signalbox after operations conclude (in early October) in order to re-decorate the building and carry out some repairs. We’ll hopefully have an opportunity to refit the external walking boards at this stage as well.

Narrow Gauge

Below: Work has slowly continued on the narrow gauge revisions, in between other work on site. The new turnout has been installed and levelled, and work on the formation running away, and down the hill from this, continues.

Tramway

Below: Work to re-sign the perimeter road and Tramway continues. There is a growing pile of signage waiting for installation, and quite a bit that could do with refurbishment in situ (we need a signage group of volunteers really… any takers please contact me!). Most recently installed are these crossing signs opposite the Welfare Hall, which denote the ungated crossing that is a feature of the Tramway there. Identical signs await installation at Foulbridge – and will mean that the small modern signs in these locations can be removed. These are all-new and have been cast to our requirements by Leander Architectural in Derbyshire. They come ready painted and the next batch includes token section signage and ground frame nameboards for the line at Rowley.

Newcastle 114

Below: The tram has now received the topcoat of yellow, which was mixed to improve its appearance. The original livery specification as Cadmium Yellow – but we found that BR Warning Panel Yellow to be a very good match, and just needed knocking back a little to take the harshness out of it. The signwriter is booked for September and he’ll make a start then on the complex lining out that is a feature of the NCT livery. The black ironwork and dash panels will also be tidied up and re-varnished as part of 114’s refresh. Work on the controllers is awaiting a gap in the programme so that they can be dismantled and closely inspected.

Samson’s night out…

Below: Matt Ellis reported that Samson had enjoyed a run out on the Ffestiniog Railway one evening in July, when the weather was damp and allowed it to venture out (the loco would not conform to their dry-weather fire restrictions otherwise). It was used for a departmental evening out, and ran to Rhiw Goch (where it is planned to operate it to in October).

Below: Running back downhill, with the lamp lighting its way…

Below: Owners of ‘The Book of Samson’ may recall my observations regarding the high embankment at Cornish Hush rather resembling that at Cei Mawr on the Ffestiniog Railway. Well, here is Samson on Cei Mawr, giving a little flavour of what the original Samson may have looked like atop the high embankment in Weardale…

Below: The embankment on the Cornish Hush – Bollihope tramway…

Photos in this post by: Chris Armstrong, Duncan Ballard, Phil Doran, Matthew Ellis, Paul Jarman, Phil Smith

Recent Comments