T&I News 19 2021…

We’ve a strong engineering bias to this week’s post. Matt has been taking detailed photographs of various processes that are often referred to but not shown in full, so hopefully this will be of interest to readers. The principle feature follows the engine overhaul of the Fordson Super Major, which we hope to hand back to its team shortly. The other Fordson tractor (the somewhat older ‘N’ is still under repair following receipt of the new radiator bottom tank casting.

Crosville 716

Below: After more adjustment and checking, the Cub has had a further visit to Go North-East to see if the already improved braking system could be bettered yet, which it has been. Here the bus mixes with a vehicle 88 years its junior! A date for MoT has been booked and we still hope to see it enter service in July at some point, all being well…

Engineering

There has been a lot of engineering work taking place in recent weeks, so Matt has compiled some captions to accompany his images in this section of this week’s post. The first batch of images all relate to the Fordson Super Major tractor.

Below: Having seen the old liners removed (see an earlier blog post), here we see the new liners fitted into the cylinder block.

Below: The pistons are being renewed, so the circlip retaining the gudgeon pin is removed, followed by knocking out the gudgeon pin itself.

Below: New and old pistons for comparison.

Below: As the gudgeon pin is a tight fit in the pistons, it was necessary to ease the fit, to do which the pistons are heated gently (in this case in a bucket of near boiling water). This causes the piston to expand slightly, making gudgeon pin insertion an easy task. Once in, new circlips are fitted to retain it (second image).

Below: All four pistons renewed.

Below: Next up are the piston rings, usefully supplied in packaging which indicates the location of each ring. Unfortunately I missed the fitting of the rings and fitting the pistons to the bore. One for a future rebuild and blog post maybe…

Below: All pistons fitted into their bores

Below: The associated big ends located on the crankshaft, with bearing caps fitted. The big end bearing shells have also been renewed during this overhaul.

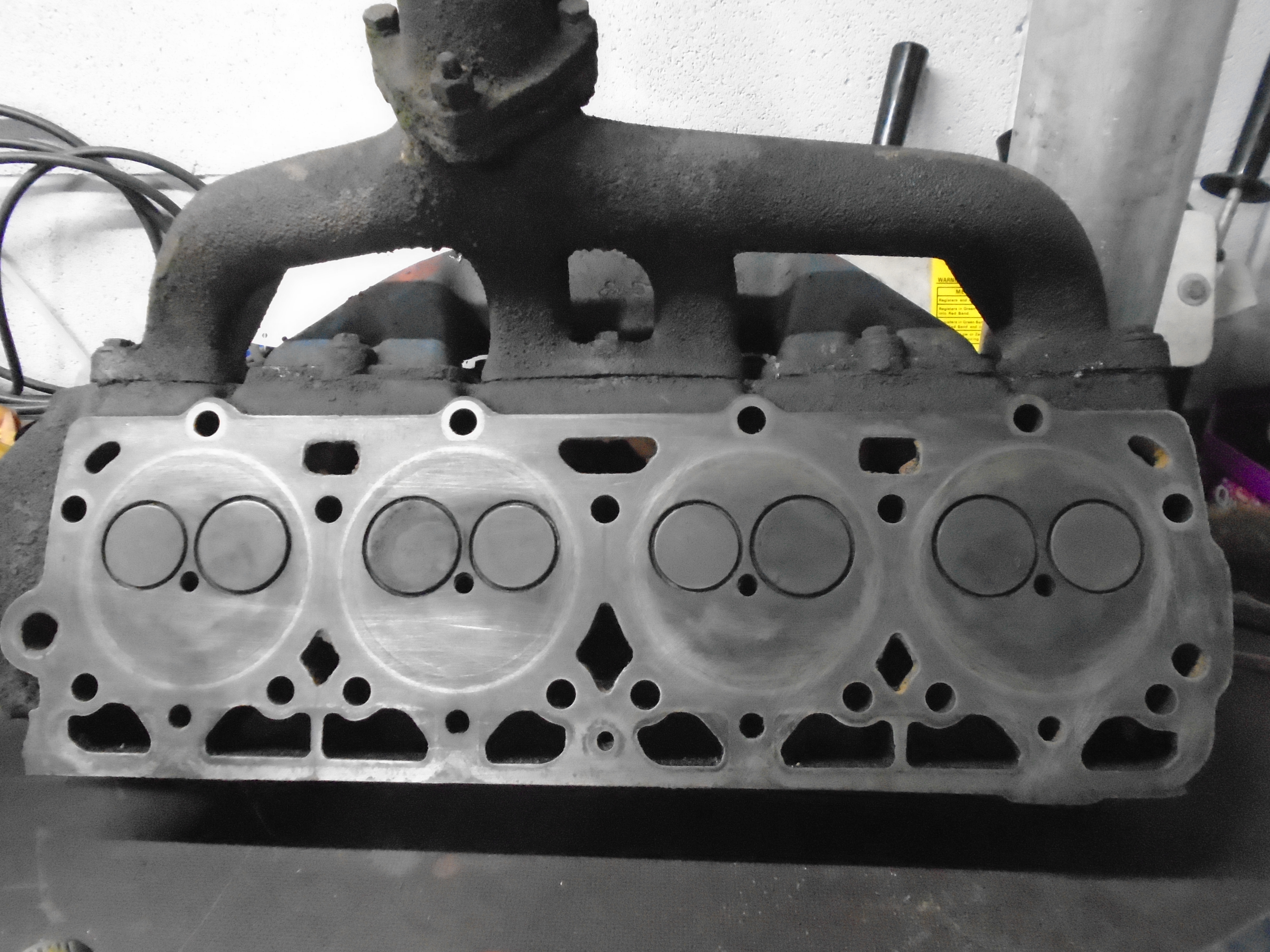

Below: The cylinder head has been cleaned up ready for refitting, as seen in this view.

Below: The new cylinder head gasket fitted to the block ready for the head to be fitted.

Below: The array of gaskets which are required for refitting the various covers and manifolds. The engine will be assembled to the point where the coolant system can be filled and then will be left overnight to ensure the liner seals are doing their job. Leaving the sump off will allow the display of a pool of water on the floor tomorrow morning should the seals not be working effectively. Provided the floor is dry, the sump can be refitted, the engine filled with oil and then tested.

There are a few remaining jobs to complete on the rest of the tractor, after which it can re-enter service with the farming team.

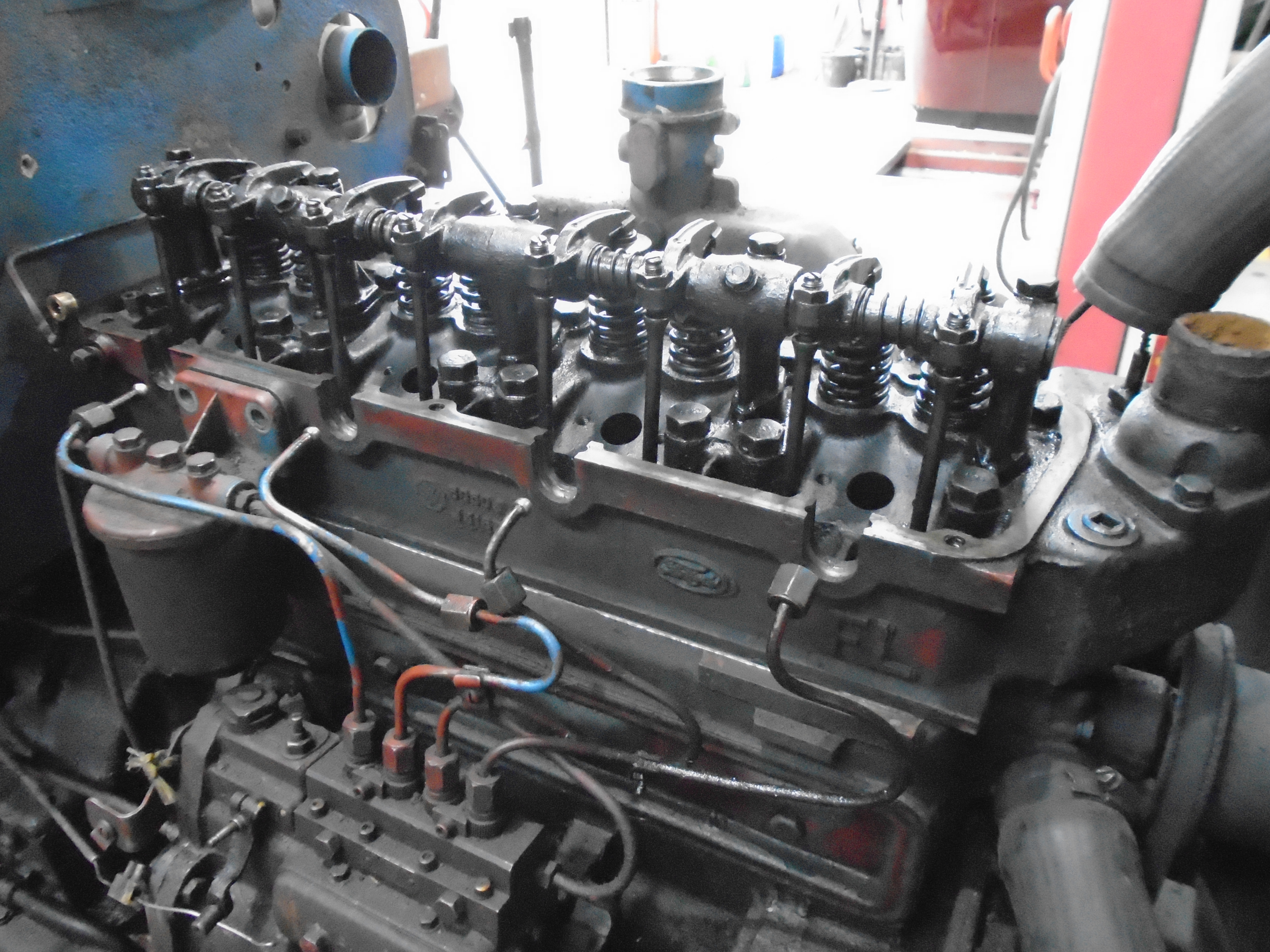

Below: The cylinder head refitted and torqued down onto the gasket. The pushrods have then been fitted, along with the rocket shafts, these both transmit the motion of the cam shaft to the inlet and exhaust valves fitted in the cylinder head. The holes which can be seen between each pair of push rods are for the fuel injectors, which await fitting.

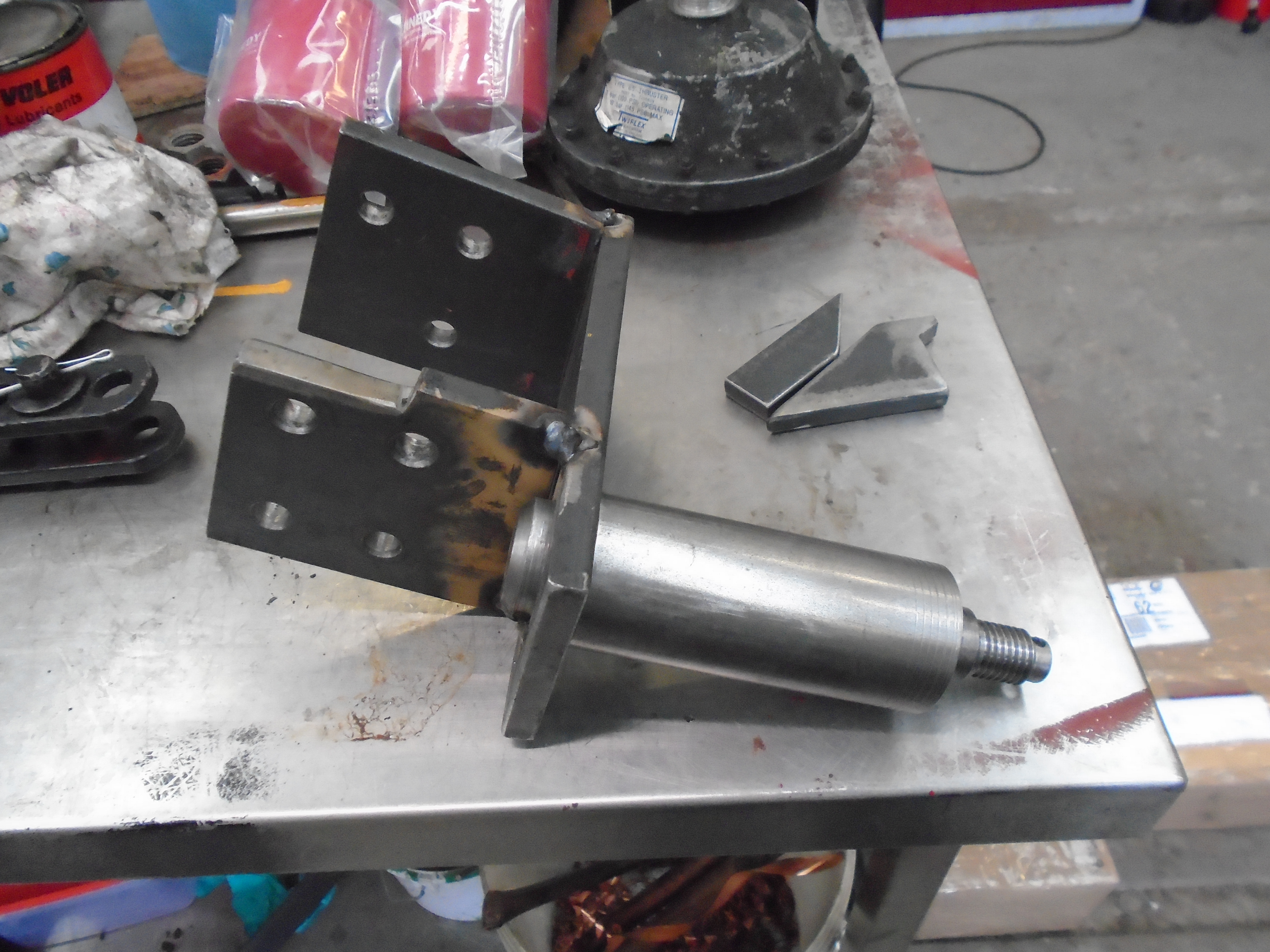

Below: Over on the steam side of the fence, Puffing Billy’s handbrake modification/repair is drawing to a close and by the time you read this, the locomotive should be undergoing testing prior to entering service. The replacement brake calliper is a much more substantial piece of equipment than that which it replaces. The action of the linkage that the new calliper requires is slightly different to the old one, so a new pivot and bracket were required. Here we see the new pivot and associated bracket, tacked up (whilst assembled on the loco) ready for welding.

Below: The same bracket, following completion of the welding work. It is now fitted to the locomotive in readiness for testing this week.

Looking forward to having a ride in this vehicle & pretend I’m travelling from Wrexham town centre to Croes Newydd steam shed – 55 years ago!