T&I News 18 2021…

We roll onwards towards the summer, with various jobs receiving attention. The priority is to commission Crosville 716, complete the repairs to Puffing Billy and the accessible Waggonway coach, undertake some permanent way work and prepare some of the trams for the proposed Circular Tours in the autumn. We are trying to ensure our focus us on the things that are essential to the operation, with some of the nice-to-have elements being on hold for the time being. We still have very few of the team working full-time, as the furlough scheme is still a critical component in the museum’s recovery planning, and we have yet to bring back volunteers in any numbers, due to the restricted staff time available to liaise with them. However, we have been talking to the Friends of Beamish board regarding a return to volunteering for some of their members, and the methods by which we will do this with appropriate social distancing etc. in place.

Speaking of social distancing; whilst the UK Government has indicated that restrictions could ease further in July, even if they do, we will probably find there is an onus on us as an employer, visitor attraction and public site to ensure that staff, volunteers and visitors alike feel safe. To this end, discussions are being held nationally regarding what the likely, and appropriate, levels of restrictions will be once they cease to become a legal requirement. For example, we may continue to advise the wearing of face coverings indoors, that social distancing remains appropriate within buildings and we may have to cap the numbers who can enter enclosed spaces – buses and tramcars being a good example of this. I think there will be little appetite for crush-loading the last tram or bus of the day once again for example.

There is a lot of work going on behind the scenes to prepare for this rather uncertain concept, and of course there will no doubt be further guidance from the UK Government and our own trade bodies, with whom our CEO works particularly closely to ensure our voice is heard. Beamish is unusual, in the national definition of ‘museum’ and so has had to lobby hard to ensure that our particularly unique arrangements (i.e. that we are not a single building or gallery, that we are largely outdoors, we run our own transport and have a diaspora of retail and food outlets) are considered when rules or guidance are set.

So, onto the news…

Crosville 716

Below: Here are a couple of views to add to the last post, showing 716 at the new Consett bus depot, operated by Go North East and where it was visiting in order to undergo brake testing on the rolling road there. Russ took these views, which I wasn’t able to include in T&I News 17.

Outdoor works

Below: The first section of fencing in a three-phase programme of renewal and enhancement work around the Pit Village and Colliery has been completed. This will now open up new views of the narrow gauge railway when it is operating as well as greatly ease the set-up for events etc.

Below: The second section is seen under construction, creating a safe and enclosed viewing area within the top yard of Colliery. This area had previously required road access, for deliveries etc, but since the area to the rear of the Sinkers was opened, this is no longer the case and a more suitable period space is to be developed here enabling visitors to view some of the narrow gauge collection and watch operations more closely. The fence will also extend to the left hand side of this view, following the line of the rope fence as far as the iron railings.

Below: The gate marks the limit of visitor access, but also a means of utilising the siding should we require. The bricks, positioned like standing stones, mark the positions of posts that will eventually support a canopy, in order to provide somewhere for the Simplex and one waggon to be parked out of the weather, or to be used as an additional locomotive preparation area during events when we have visiting engines. The sketch beneath shows what is planned…

Below: Another view of the top yard during construction of the fence. The area to the right of the present locomotive shed (beyond the contractor’s lorry) is earmarked for a lean-to shed extension, to be accessed via a new turnout just before the water tower. I need to find a kind donor or some funding to purchase said point, but we have the plain rail for the siding. This will then provide a shed (which itself we intent to enhance and adapt) to house both Glyder and KS 721 or Samson, to improve the ease of operation for running days (and centralise the locomotive facilities in this area). This view is also a reminder of how green this area has become and that, at some point, a decent gardening session is needed!

Below: Current thinking is to add a lean-to to the side of this shed, and a bothy to rear. With access to the front via a new siding. This should put things in a more prominent view for visitors, including preparation and disposal times for the locomotives. We also need some better facilities here to store items such as oil, boiler treatment etc.

Below: By the end of the week, the second phase fencing was nearing completion. Phase 3 will be the renewal of the fencing to the rear of Francis Street, to enable removal of the badly decayed sleeper fencing in this location. It would be nice to replace sleepers with sleepers, but for safety we need a rapid solution, which the close boarded fencing provides (and I really wouldn’t want any more three-rail fencing in this area!).

Below: Another job nearing completion is the re-wiring of the Colliery Engine Works, which is being carried out by the museum’s in-house electricians. I remember the struggles back in 2004 to get the lights to work – now they will work reliably, the plug sockets will function and there will even be hot water to wash hands in! Luxury! The lights, now consistent and no longer intermittent, can be seen in the photos below.

In the tram and bus depot…

Below: One thing that Crosville 716 was lacking was a speedo. There was no speedo drive within the gearbox and when the project started, we didn’t envisage taking the bus anywhere that this might matter. However, with the changes made in recent years to the way in which we manage the bus fleet, and fortunate access to Go North East’s facilities for testing, it as deemed prudent to fit one. Unfortunately the choice was limited as it has to be a GPS unit, for now anyway. In the future we will aim to install a period unit and the mechanism to drive it, so for now we have to hold our nose and live with this one! We intend to screen the digital display however to try and reduce the modern appearance.

Below: Sheffield 264 has been placed onto the pit for a brake inspection. The Beamish Tramway Group have also made some adjustments to the wiring plan on this car, to reflect what is fitted rather than what is theoretically specified for it.

Below: Oporto 196 has reverersed places with 264 in order for the latter to fit over the pit – creating some change in the tram depot layout for the first time since March 2020!

Below: Peter sent through a couple of images showing the trams during the shunt – with the comment that it is a breif glimpse of normal times… Hopefully it won’t be too long before this becomes the norm again, and certainly 2022 should see us reach a point that we can resource and operate the tramway, free of social distancing restricions and offering a regular service around the site.

Below: The Daimler D-Type bus has had its solid tyres refitted – I’ve said it many times here before, but it looks so much better on these than on the pneumatic tyres, and as it is not visiting the Pit Village (due to the condition of the road there), the discomfort these might cause is limited to the Town Street, which is run empty at present in any case! We are a museum and we do try our best to make things right, even if they aren’t always the most comfortable options!!!

Below: Peter Barlow, from the Beamish Tramway Group, has been manufacturing dewirement buzzer boxes in his home workshop. Here is the prototype box, within which the components uses have been updated over previous generations of this design. These are what generate the distinctive buzz when the trams cross the dead-sections of overhead in service, and which fade into silence when the trams are put away at night and de-energised; another sound we probably hadn’t noticed we’ve missed over the last 16 months.

Waggonway

Below: Repairs to the open, accessible, coach are nearing completion and painting will commence next week. We aim to have the coach back to the Waggonway in time for the school summer holidays, to enhance capacity and restore a wheelchair accessible coach to the set. We had intended to re-body the coach in 2019, but events rather overtook this, so instead repairs have been carried out to make it safe, and socially distanced, for use in 2021. Final colour? I rather favour dark green – though this depends on what we’ve got in the cupboard!

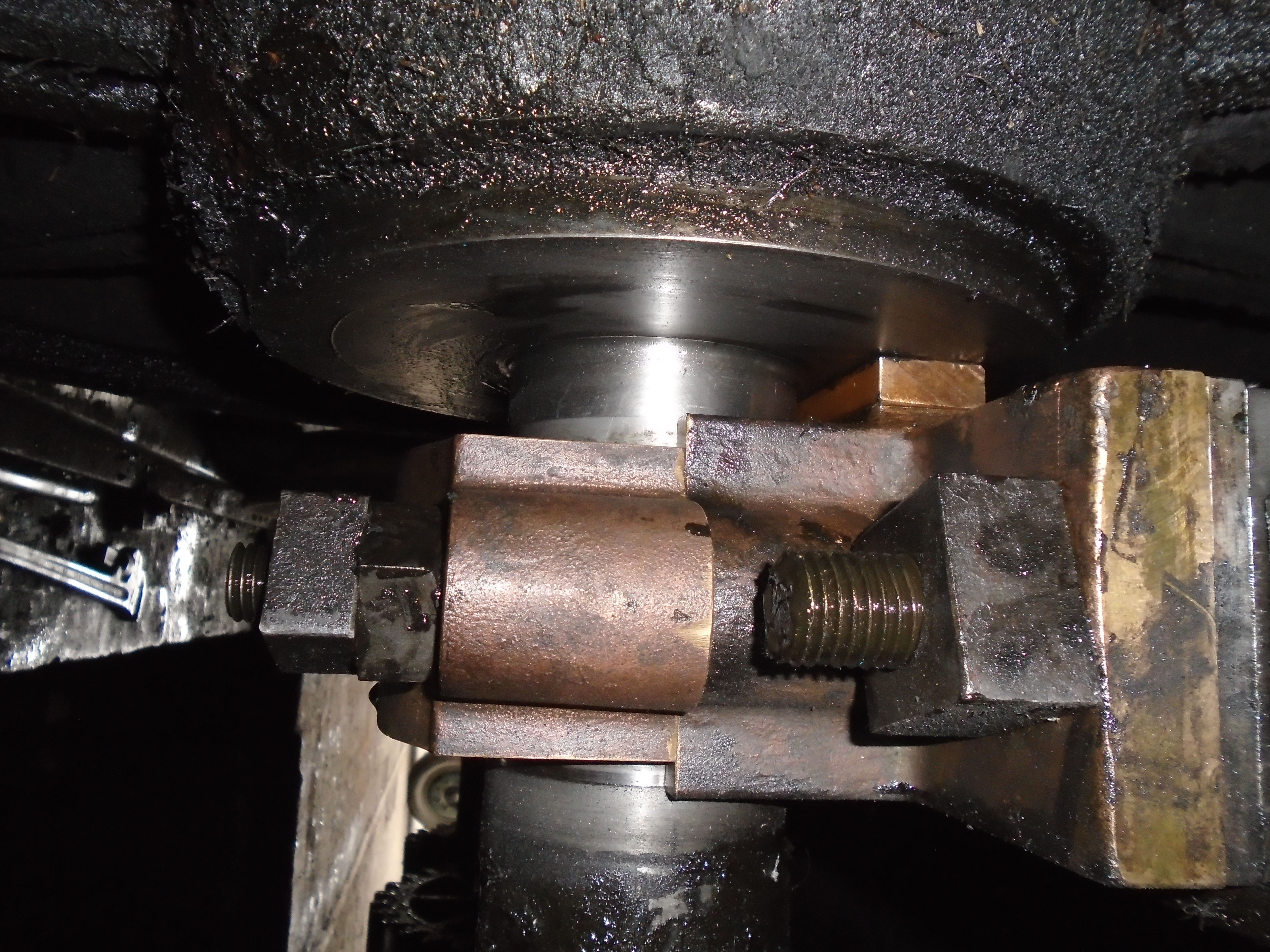

Below: The axle pedestal overhaul for Puffing Billy was seen in a previous post. Here is one of the pedestals in situ – note the replacement thrust face (the bronze rectangle to the right of the wheel boss) and its proximity to the rear of the wheel – this will control the lateral movement of the locomotive and give the brakes less work to do in terms of centring themselves on the brake disc – something that had caused wear previously.

Below: This is the new caliper mounting for Puffing Billy’s handbrake – a more substantial fixing than the locomotive had previously.

Below: In response to feedback from staff at the Waggonway, we’ve now installed steps to enable access from the ground to the floor of the compressor chaldron, without having to either board via steps, the platform or climb in via the brakegear. Daniel, one of our two apprentices, has completed the construction of the components that will enable safer access/egress from the chaldron. The steps are largely hidden by the platform when running, but come into their own when the train is parked in the shed lean-to or inside the engine shed (where it usually remains coupled to the locomotive when going on-shed). Here are the components, and Daniel with his steps, made to look suitably contemporary with the waggon itself.

Below: A test fit of the steps, which explains their role and location on the compressor chaldron. Obviously the projecting step supports will be trimmed upon completion.

Peckett 2000

Below: The 0-6-0ST, Peckett 2000, departed on Friday 25th June for its new temporary home on the Helston Railway in Cornwall. Rowley Station is now devoid of motive power, though if we find we need to carry out any shunting at Christmas in conjunction with setting up grottos, we will move Coffee Pot No.1 over there for the winter to save us shunting by hand again! Rowley Station is staffed at present, as a display, but trains are not likely to run for some time, given the backlog of track maintenance on site and costs of operation. We have also had a number of the steam team leave for other jobs, so we won’t start recruiting and training until 2022, with a lag of two years to attain the required level of competence. This takes us to 2024, when we hope Dunrobin should be somewhere near ready, and also gives us time to carry out track and infrastructure repairs in the meantime. This will leave us without a steam operation at Rowley for the next few years, but the plan is that when it does resume, it will be with our own locomotive, on refurbished track and with several other improvements completed, that have been on the wish list for this operation for some years.

In order to reach the loading pad, 2000 had to be steamed and travel from Rowley Station to Rowley East, where access by low-loaders is available. The locomotive has been very popular at Beamish and is in superb condition, thanks to the care and attention lavished upon it at its last overhaul by its owner and his contractor.

Below: 2000 is seen departing earlier (25/06/21), on its way to Cornwall – one of the longer journeys made by a locomotive leaving Beamish (though not the first time we’ve had the Cornwall connection – Alfred & Judy visiting from the Bodmin & Wenford Railway in August 2013: http://beamishtransportonline.co.uk/2013/08/steam-action-at-agricultural-power-from-the-past-day-1/

And finally…

Below: Having described the collection of two Hudson ‘Victory’ narrow gauge skips in a previous post, I took the trouble to measure their gauge (rather than guess using my boot!) and found they are 19″ gauge. This set a chain of thought in motion on the drive home – which is probably easier to illustrate than describe! The photo below illustrates the thought, the measurement and the test!!!

Below: So turns out that a 15″ gauge railway with 35lb rail, laid between standard gauge rails, rather nicely leaves a 19″ gauge railway to utilise, as Matt demonstrates here! So we have our ash railway and two historic wagons to restore and use on it.

Operations June/July 2021

A reminder of what visitors can expect to see in the next four months…

- Daily bus service using 1950s double deckers

- Wheechair Accessible Vehicle service available

- Waggonway daily from 3rd July

- Colliery Railway on the 25 – 27th June (using No.18)

- Coffee Pot running day on 9th July (joined by at least one other locomotive in steam in the Colliery area)

For now, Rowley Station, the trams, Colliery winding engine and Drift Mine remain non-operational. The Colliery Railway will be used if there are technical difficulties at the Waggonway. See Facebook (Beamish Museum) for latest information.

As ever, the above are subject to availability of locomotives and vehicles, but we work very hard to try and meet these objectives.

This is one of the most all-encompassing, varied, informative, multi-subject & very relative Transport Bulletins I’ve ever read! Well done, Paul – particularly finding time to inform with all the work that’s going on.

Hi paul, Excellent post as usual can I make a suggestion regarding when you do the track repairs at rowley, can I suggest you sort out the access to the coal drops whilst you have the opportunity to do so and relay the goods yard, so you can offer shunting demos etc, but what are your plans for the track at rowley? cheers rob

I had always been led to believe that the Great Laxey Mine Railway in the Isle of Man (now partially restored and enthusiast-operated) was the only 19-inch gauge railway in the British Isles. Now I know differently!